UHPC batching and mixing equipment

A technology of mixing equipment and batching bins, which is applied in the directions of mixing operation control, mixing operation control device, clay preparation device, etc., can solve the problems of difficulty in controlling the accuracy of material proportion allocation, low efficiency of manual allocation, waste of manpower and material resources, etc. To achieve the effect of improving the construction environment, improving the construction environment and improving the processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, invention is described in further detail.

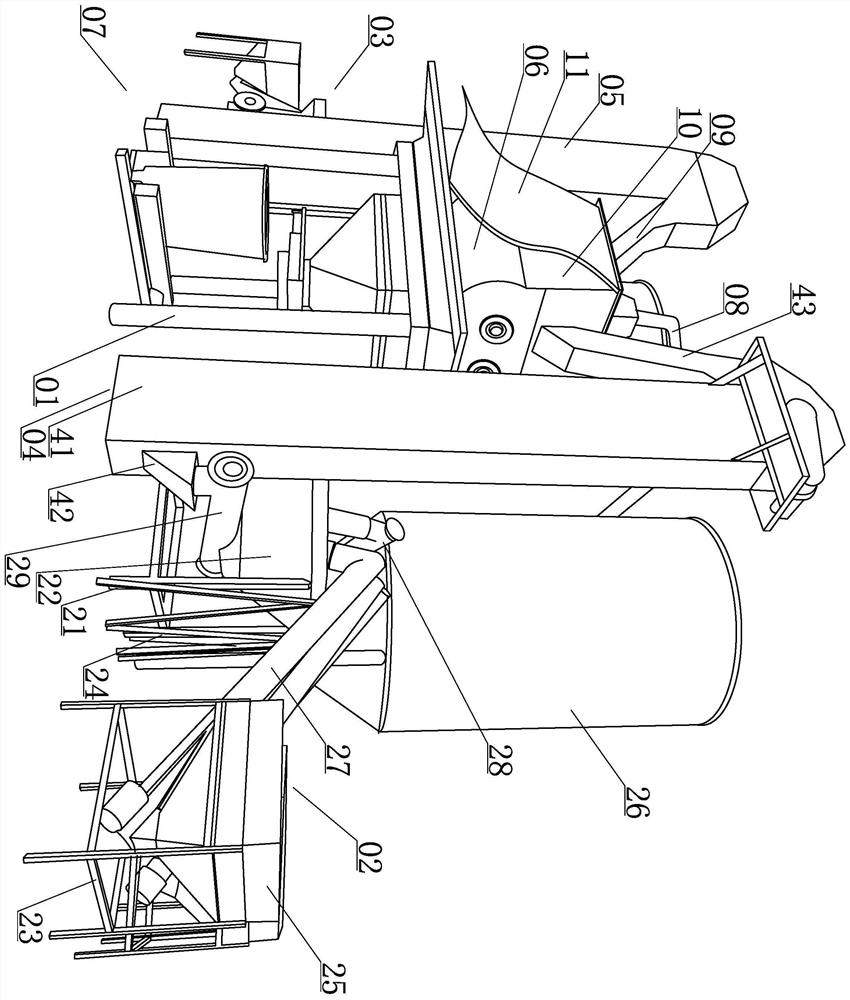

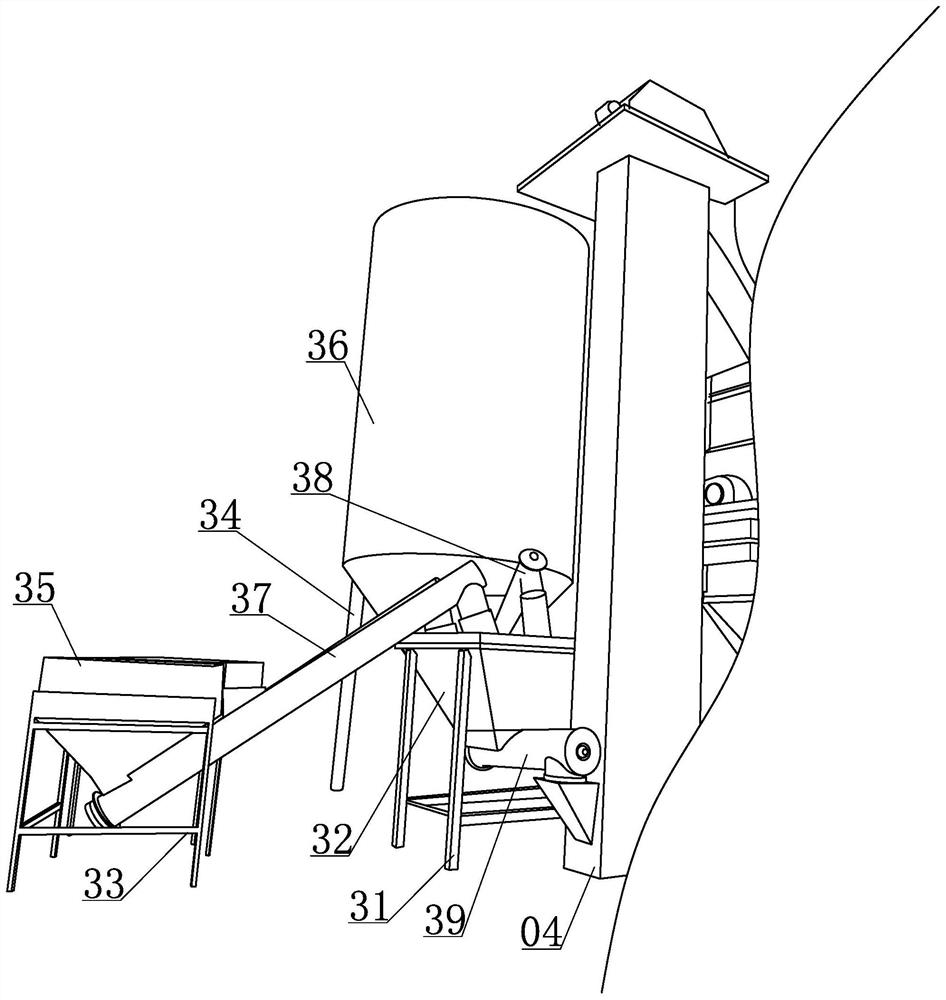

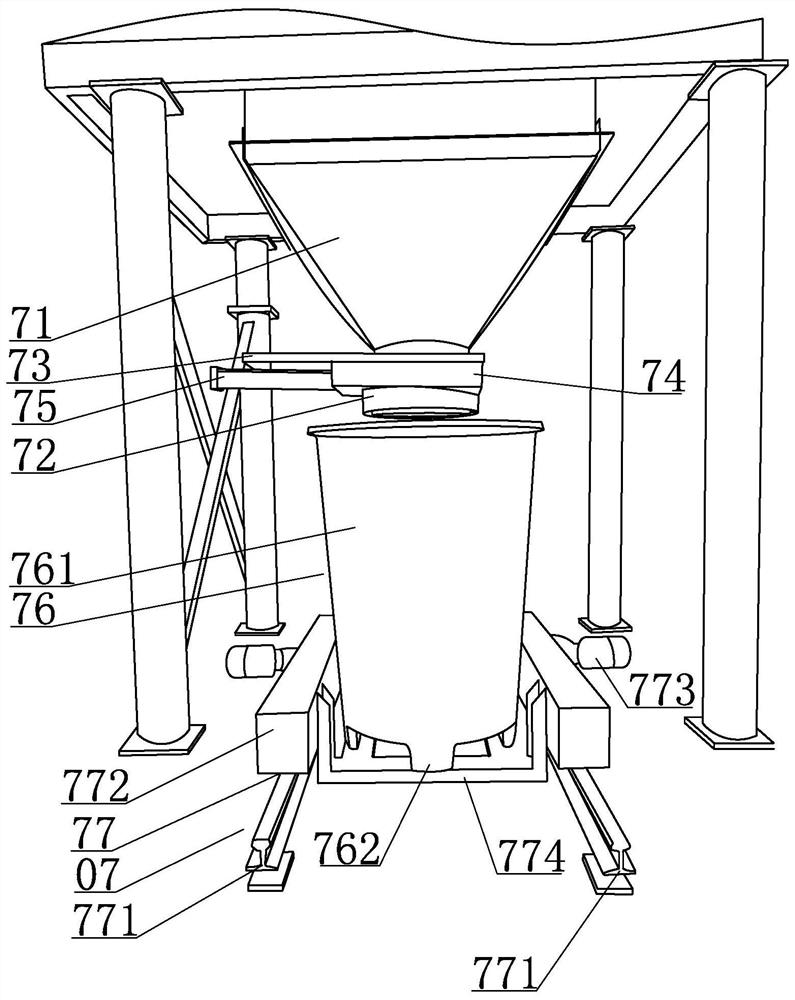

[0018] Such as Figure 1-3 As shown, a UHPC batching and mixing equipment includes a rack workbench 01, a first batching device 02 and a second batching device 03 respectively provided on both sides of the rack workbench 01, and a first batching device 02 is provided on the first batching device 02. The first hoist 04 that has, the second hoist 05 that is provided with on the second distributing device 03, is provided with the mixing agitator that communicates with the first hoist 04 and the second hoist 05 respectively on the frame workbench 01. Device 06 and the steel fiber vibration dispersing device 10 provided above the mixing and stirring device 06, and the finished product charging conveying device 07 that is provided with below the mixing and stirring device 06. A steel fiber conveyor belt 11 is arranged on the steel fiber dispersing device. The above-mentioned first li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com