Lithium negative electrode, preparation method and application thereof

A lithium negative electrode and a technology for preparation steps, applied in the field of lithium negative electrode and its preparation, can solve problems such as inability to effectively protect metal lithium, and achieve the effects of good cycle performance and improved cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

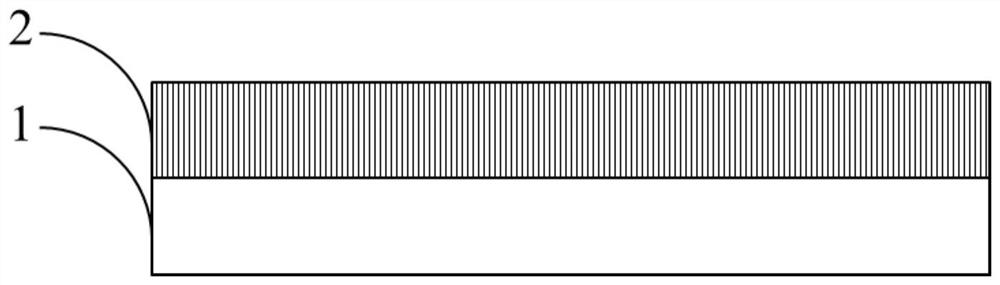

[0048] The cross-sectional structure of the lithium negative electrode provided in this embodiment is as follows: figure 1 Shown, wherein, protective layer comprises the polyimide of 87 mass parts, the LiBF of 10 mass parts 4 and 3 parts by mass of isophorone to a thickness of 1 μm.

[0049] The preparation method of the lithium negative electrode provided in this embodiment includes the following steps:

[0050] First, dissolve 4,4 diaminodiphenyl ether and pyromellitic dianhydride in the solvent NMP with a molar ratio of 1.01:1, and stir and react at 10°C for 5 hours to obtain polyimide; take 87 parts by mass polyimide with 10 parts by mass of LiBF 4 and 3 parts by mass of isophorone, mixed and stirred evenly, and the protective layer slurry was obtained after filtering the insoluble matter; finally, the protective layer slurry was coated on the surface of the lithium metal layer by dipping and pulling method, and then dried in a vacuum oven at 40 ° C. drying to obtain a ...

Embodiment 2

[0052] The cross-sectional structure of the lithium negative electrode provided in this embodiment is as follows: figure 1 Shown, wherein, protective layer comprises the PVDF-HFP of 90 mass parts, the LiPF of 8 mass parts 4 and 2 parts by mass of Solvesso 150 with a thickness of 0.6 μm.

[0053] The preparation method of the lithium negative electrode provided in this embodiment includes the following steps:

[0054] Dissolve 90 mass parts of PVDF-HFP in solvent NMP, add 8 mass parts of LiPF 4 and 2 parts by mass of Solvesso150, stirred evenly, and the protective layer slurry was obtained after filtering the insoluble matter; the protective layer slurry was coated on the surface of the metal lithium layer by casting method, and dried in a blast drying oven at 40°C to obtain a lithium negative electrode .

Embodiment 3

[0056] The cross-sectional structure of the lithium negative electrode provided in this embodiment is as follows: figure 1 As shown, wherein the protective layer includes 50 parts by mass of PEDOT, 45 parts by mass of LiFSI and 5 parts by mass of lithium dodecyl sulfate, with a thickness of 0.5 μm.

[0057] The preparation method of the lithium negative electrode provided in this embodiment includes the following steps:

[0058] Dissolve 50 parts by mass of PEDOT in the solvent toluene, add 45 parts by mass of LiFSI and 5 parts by mass of lithium dodecyl sulfate, stir evenly, and obtain a protective layer slurry after filtering the insoluble matter; The layer slurry is coated on the surface of the metal lithium layer, and dried in a blast drying oven at 30° C. to obtain a lithium negative electrode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com