Pouring sealant for potting of torque motor rotor and pouring method

A torque motor and motor rotor technology, which is applied in the field of potting glue and potting for torque motor rotor potting, can solve problems such as cracking of the glue layer and shaft sleeve cracks, and achieve the elimination of air bubbles, high bearing strength, and avoid abnormal operation of the motor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

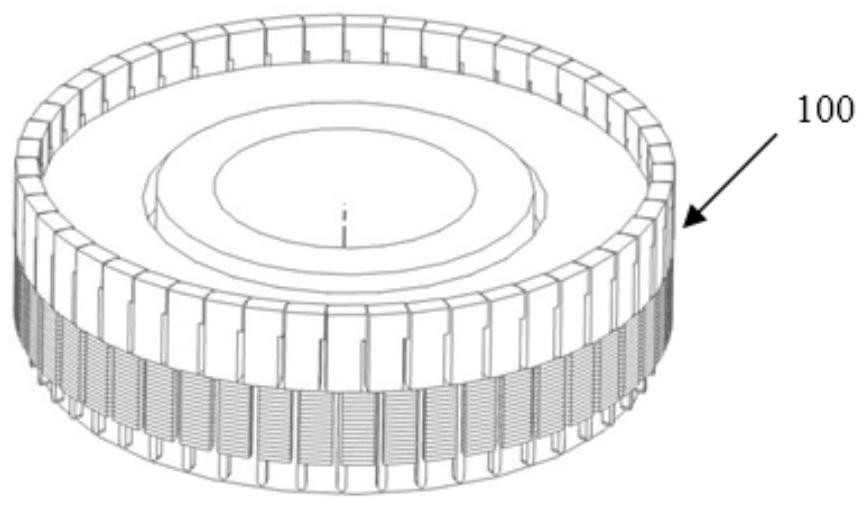

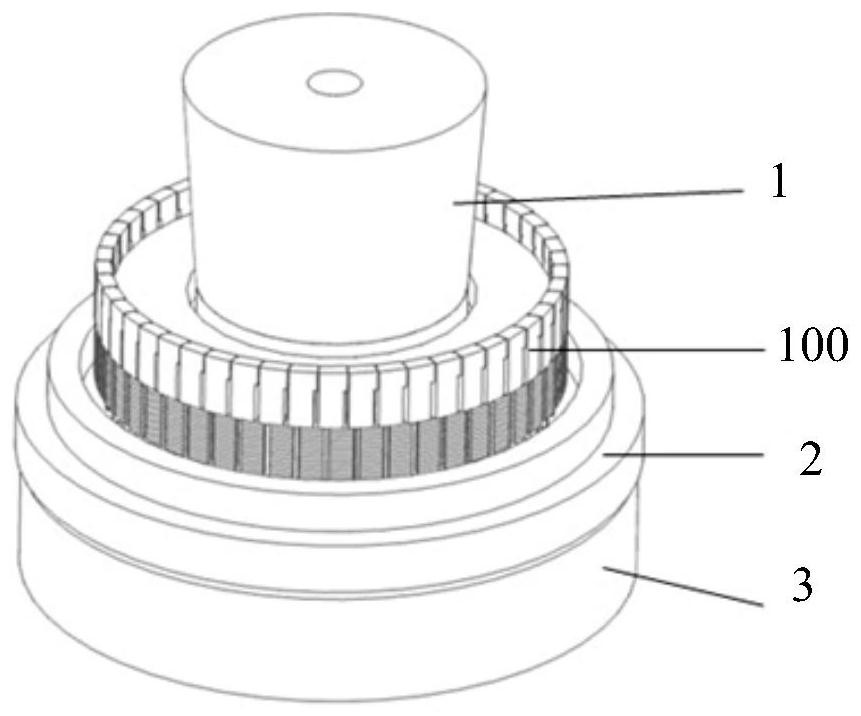

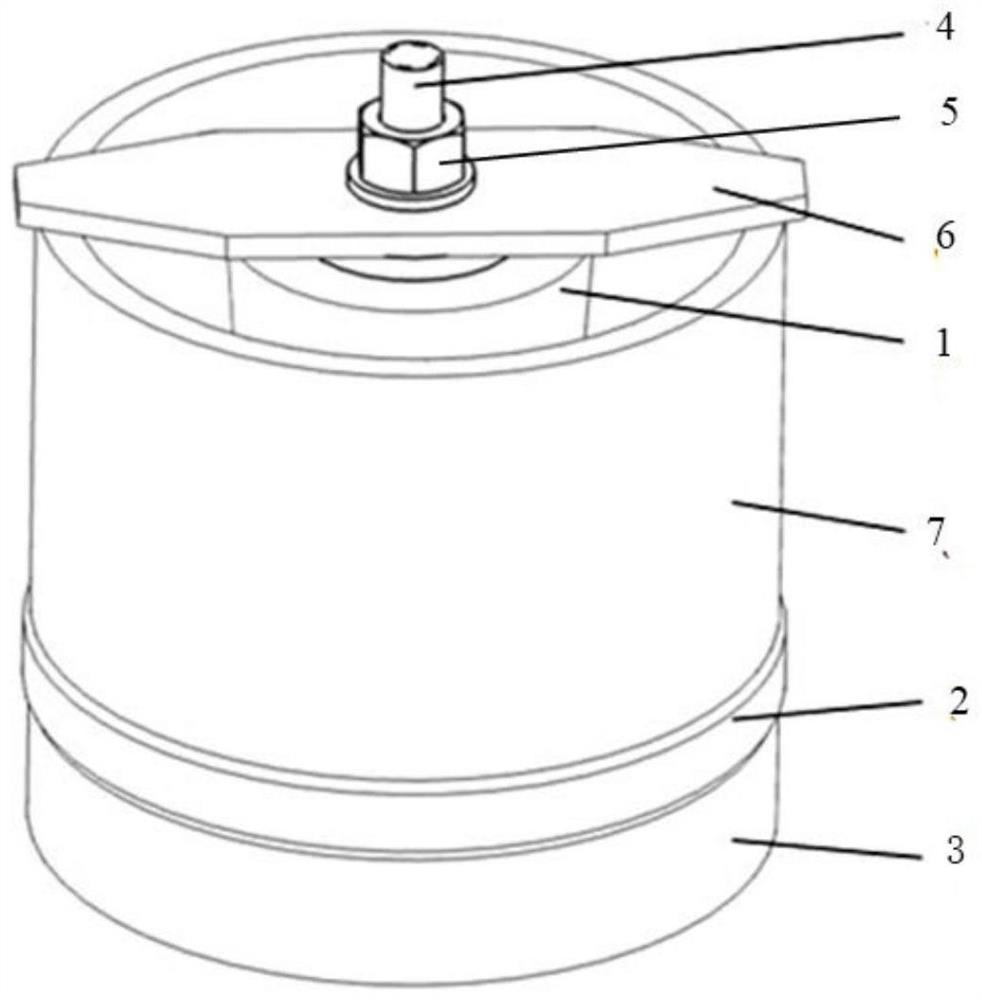

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the drawings and specific examples. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0034] A potting glue for torque motor rotor potting, the invention point of which is: it is composed of the following raw materials in parts by weight:

[0035] Use E-51 type epoxy resin with large production volume and low cost as the main component of the rotor potting compound, use liquid anhydride HK-021 as the curing agent for the epoxy resin, and use silicon micropowder as the filler for the epoxy resin On the one hand, improve the thermal conductivity of the colloid, on the other hand adjust the linear expansion coefficient of the colloid, in order to improve the flexibility and impact resistance of the colloid, add a certain amount of epoxy toughener CMP-410, and add the accelerator DMP-30 to promote the group sub-res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com