Assembly type installing structure for prefabricated outer wall doors and windows

An installation structure and assembly technology, which is applied in the direction of fastening/covering of the base frame and joints, drainage of condensed water, etc., can solve the problems that the doors and windows cannot be built with the same life span, difficult to be replaced by the owner, and difficult to control the construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

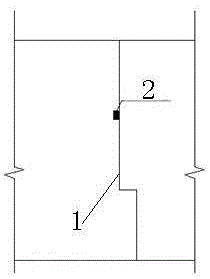

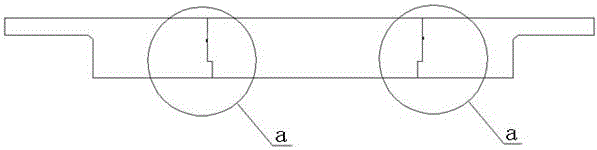

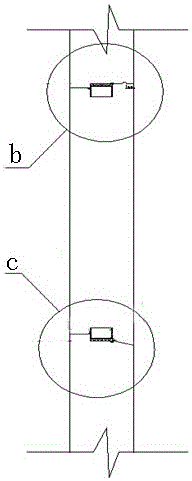

[0019] Such as Figure 1-5 Shown: An assembly type prefabricated external wall door and window installation structure, the window frame is provided with grooves 1 and glue grooves 2 in turn from inside to outside, a drip line 3 is arranged outside the glue groove on the top of the window frame, and the bottom of the window frame Find a 1% slope 4 and do flashing 5 at the glue tank.

[0020] Through the rebate, there is a concrete interface between the window and the interior. The sealing material is not directly connected with the interior. Even if the sealant is damaged and the foaming agent is not dense, the water flows to the rebate position to block, and the position of the bottom window is found. Slopes, water can be drained to the outside by gravity.

[0021] The rebate and other concrete are poured together, and the integrity is good, and there will be no cracks that may be caused by the rebate of the cast-in-place structure.

[0022] The height difference between ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com