High-density ceramic fiber board with curved surface structure and preparation method thereof

A technology of ceramic fiber board and curved surface structure, applied in the field of ceramic fiber board, can solve the problems of powder sinking, affecting product quality, fiber floating, etc., to achieve good wrapping ability, reduce raw material pretreatment links, and prevent cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] The present invention provides a method for preparing a high-density ceramic fiberboard with a curved surface structure described in the above technical solution, comprising:

[0066] mixing inorganic composite fibers, organic fibers, glass fiber chopped strands, refractory fillers, cationic organic binders and anionic inorganic binders to obtain slurry;

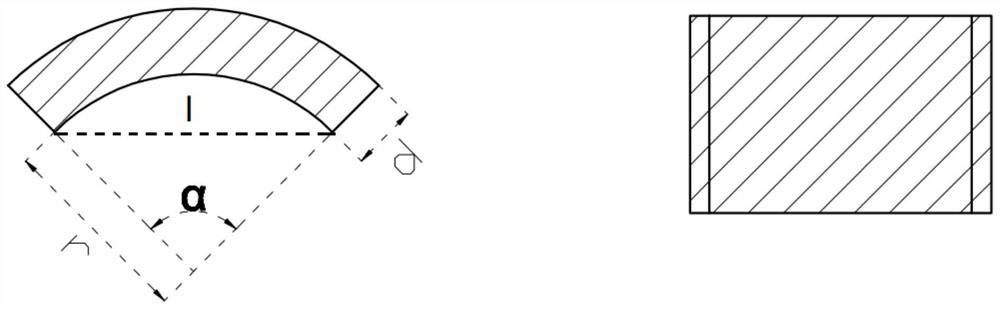

[0067] After the slurry is formed, it is pressed with an arc-shaped mold to obtain a wet billet;

[0068] The wet body is dried to obtain a high-density ceramic fiber board with a curved surface structure.

[0069] In the present invention, the inorganic composite fiber preferably includes at least one blown fiber and two kinds of spun fibers. The blown fiber refers to a fiber prepared by blowing, and the blowing method can use existing There is an existing process in the technology, and the ejected fiber has the characteristics of thin fiber diameter and short fiber length; the spin-off fiber refers to ceramic fiber...

Embodiment 1

[0107] Soak 200Kg of wood pulp fibers in water for 24 hours, then add 2 tons of water to the Volta beater, turn on the Volta beater for beating for 25 minutes, add water to dilute, make a slurry with a mass concentration of 5%, and pump it into a wood pulp storage tank for standby.

[0108] Add 3 tons of water to the hydropulper, add 80Kg of ceramic fiber high-purity spinning cotton, and beat for 10 minutes; then add 80Kg of ceramic fiber standard blown cotton, and beat for 5 minutes; then add 200kg of soluble ceramic fiber, Beat for another 5 minutes and then add 150Kg of wood pulp fiber slurry, mix and beat for 5 minutes.

[0109] Add 9Kg of glass fiber chopped strands with a length of 10mm to the hydraulic pulper, mix and beat for 3 minutes.

[0110] Add 250Kg of Guangxi white mud and 150Kg of white silica powder to the hydraulic pulper, mix and beat for 5 minutes.

[0111] Add 60Kg of cationic potato hot-soluble starch, add water to dilute the mass concentration of the co...

Embodiment 2

[0122] According to the method of Example 1, the high-density ceramic fiberboard with curved surface structure is prepared. The difference from Example 1 is that the ceramic fiber high-purity spun silk cotton is replaced by the ceramic fiber standard spun silk cotton, and the structural size of the arc-shaped mold is adjusted. .

[0123] According to the method of Example 1, the high-density ceramic fiberboard with curved surface structure prepared in Example 2 of the present invention is tested, and the test result is that the bulk density of the high-density ceramic fiberboard with curved surface structure prepared in Example 2 of the present invention is 834Kg / m 3 , the compressive strength is 6.8MPa, the average thermal conductivity at 350°C is 0.106w / (m·k), and the heating permanent line change rate at 1000°C for 24 hours is -1.0%; the chemical composition includes: SiO 2 The mass content is 69.6%, Al 2 o 3 The mass content of CaO is 15.2%, the mass content of CaO is 6....

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com