A kind of quantum dot LED and preparation method

A technology of quantum dots and quantum dot layers, which is applied to semiconductor devices, electrical components, circuits, etc., can solve problems such as temperature rise, luminous efficiency reduction, and fluorescence efficiency reduction, and achieve smooth surface, uniform thickness, and improved light output efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following descriptions of various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the present invention can be implemented.

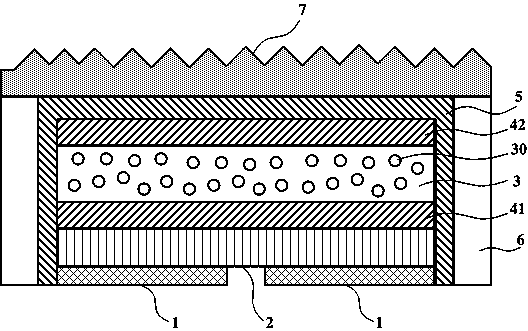

[0034] Please refer to image 3 As shown, Embodiment 1 of the present invention provides a quantum dot LED, including:

[0035] A pair of electrodes 1 arranged side by side and spaced apart;

[0036] A flip-chip LED chip 2 disposed on the electrode 1 and electrically connected to the electrode 1;

[0037] A quantum dot interlayer disposed on the flip-chip LED chip 2;

[0038] An encapsulation layer 5 covering the electrode 1, the flip-chip LED chip 2, and the quantum dot interlayer;

[0039] A white glue layer 6 surrounding the encapsulation layer 5 .

[0040] Specifically, this embodiment adopts the flip-chip LED chip 2 , which has good heat dissipation, high reliability, can withstand high current driving, and has high cost performance.

[0041] The quantum dot interlayer specifically includes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com