Ocean engineering composite column

A technology of marine engineering and composite columns, applied in the field of composite columns, can solve problems such as erosion, inconvenient construction, casing cracking and damage, etc., and achieve the effect of outstanding corrosion resistance, excellent corrosion resistance, and reduced maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

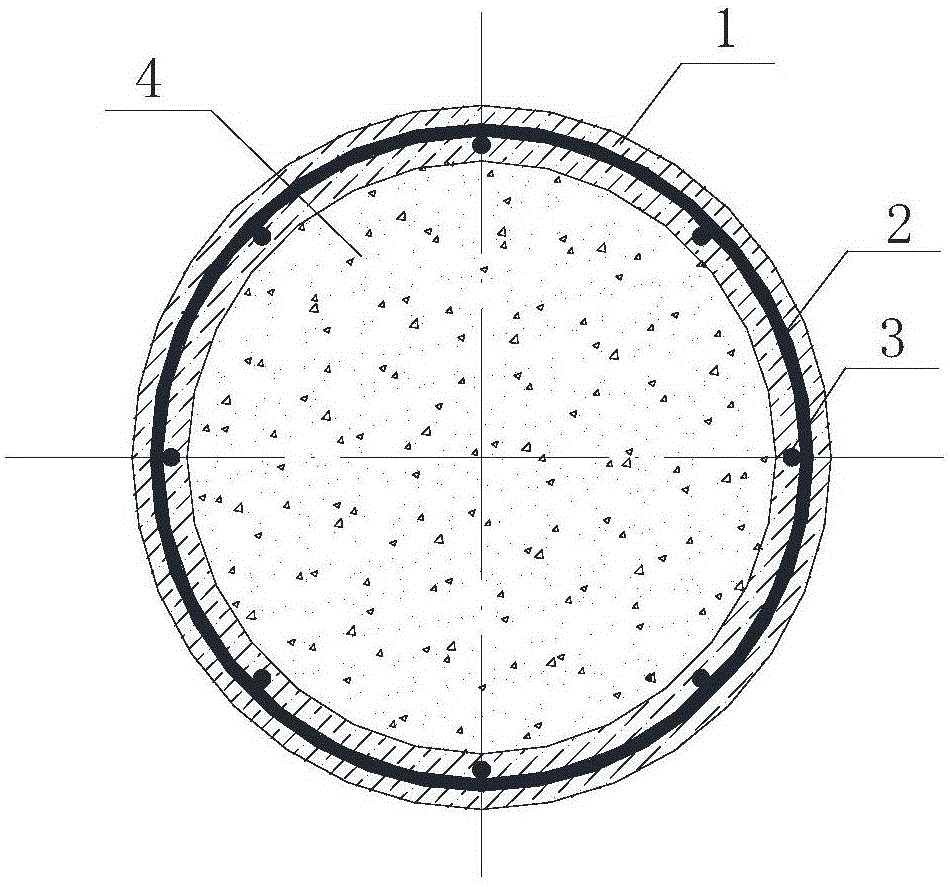

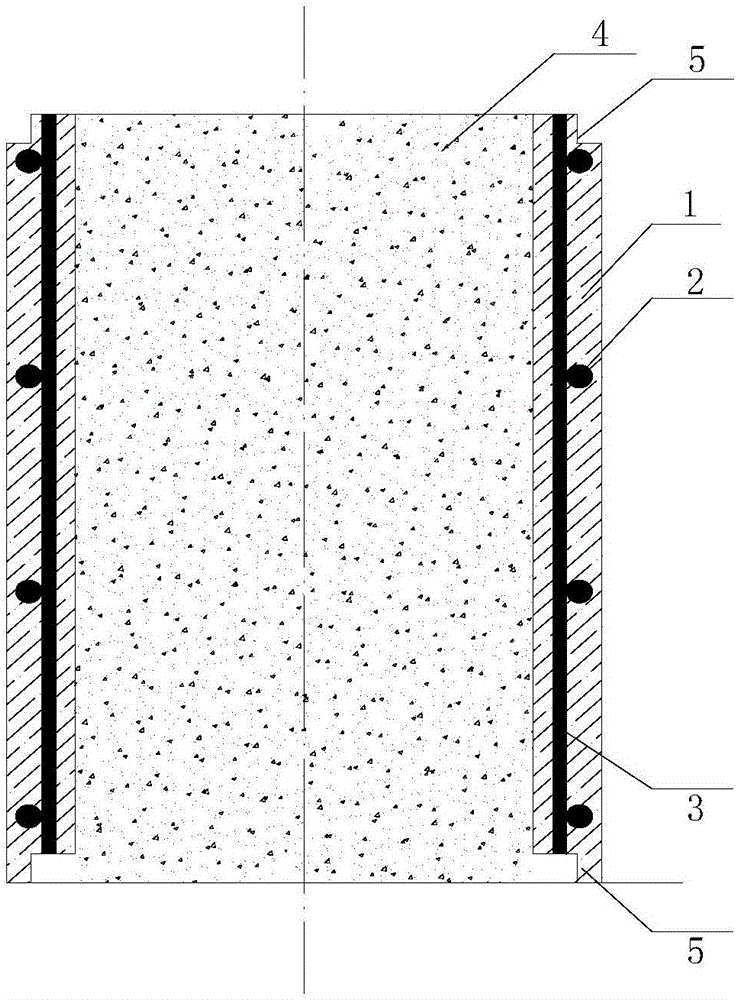

[0022] As shown in the accompanying drawings, the present invention is a marine engineering composite column, comprising active powder concrete casing (1), stirrup (2), longitudinal reinforcement (3), concrete column (4), stirrup (2), longitudinal The reinforcement (3) is arranged in the active powder concrete casing (1), and is characterized in that the stirrup (2) and the longitudinal reinforcement (3) are respectively closed fiber reinforced plastic stirrups (2) and fiber reinforced plastic longitudinal reinforcements (3 ), and in the active powder concrete of the sleeve (1), the corrosion-resistant short fibers are mixed, and the two ends of the active powder concrete sleeve (1) are respectively provided with connectors (5) for connecting the sleeves to each other, such as figure 1 and figure 2 shown. During implementation, first, according to the design requirements, the closed fiber-reinforced plastic stirrups (2) and fiber-reinforced plastic longitudinal bars (3) are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com