Antenna packaging structure and manufacturing method thereof

A technology of packaging structure and manufacturing method, applied in the direction of antenna support/mounting device, antenna, slot antenna, etc., can solve the problems of reducing antenna radiation performance, antenna cavity height instability, poor antenna performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In an existing AiP antenna package structure, the antenna and the chip are directly manufactured in one package.

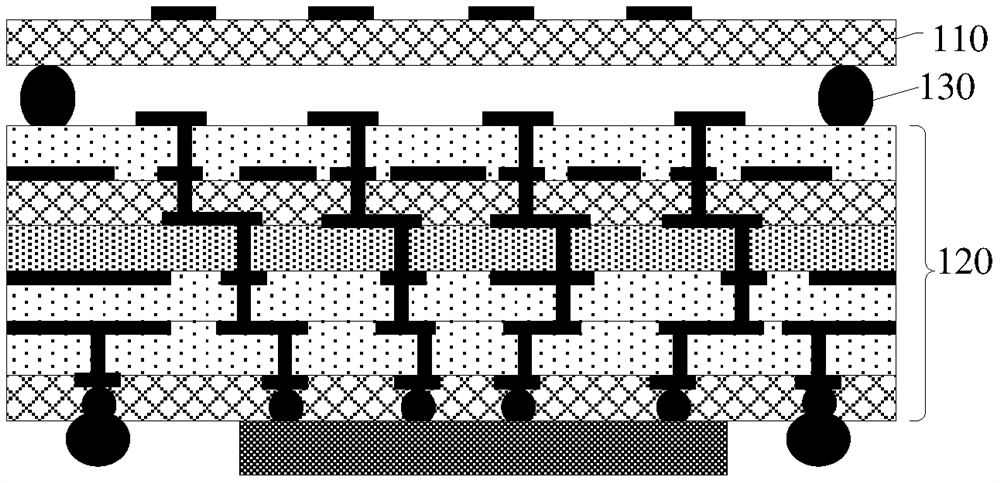

[0046] In the existing AiP antenna packaging structure, such as figure 1 As shown, the upper and lower substrates 110 and 120 are welded together by solder balls 130 , and the height of the solder balls 130 controls the distance between the upper and lower substrates 110 and 120 , that is, the height of the antenna cavity.

[0047] However, the solder balls are thermally unstable, and metal melting will occur at high temperature, resulting in highly unstable solder balls, and thus unstable distance between the upper and lower substrates.

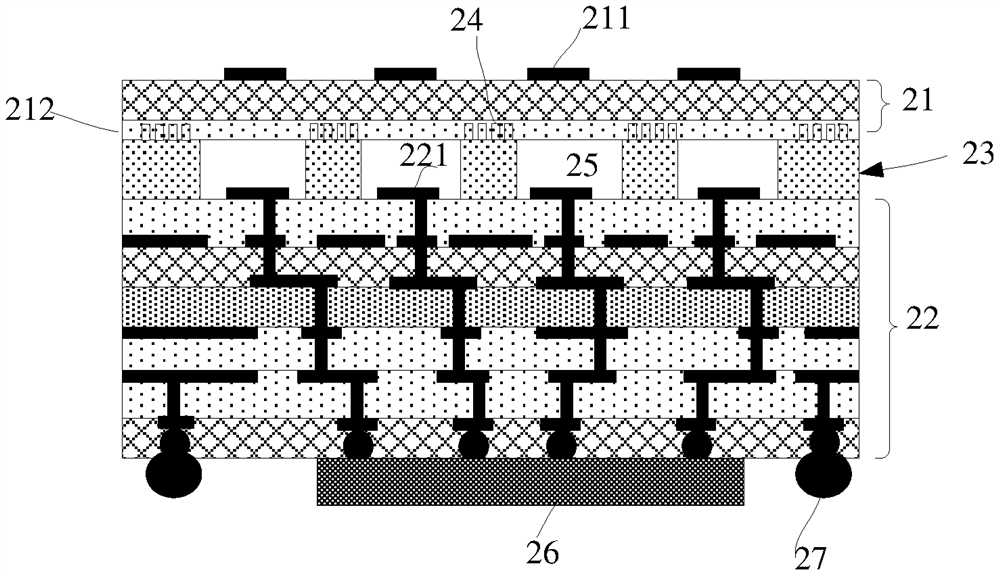

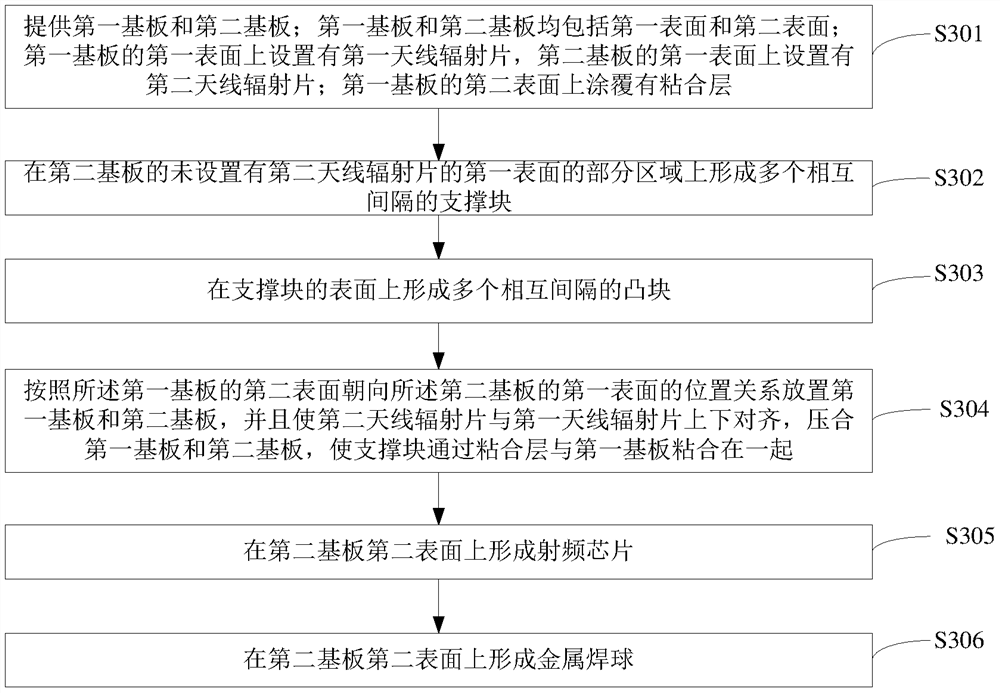

[0048] In order to solve the problem of unstable distance between the upper and lower substrates in the AiP antenna packaging structure, the present application provides a new antenna packaging structure. In the antenna packaging structure, a plurality of support blocks spaced apart from each other are arranged between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com