Display and dismountable light source structure thereof

A detachable, light source technology, applied in the direction of instruments, optics, nonlinear optics, etc., can solve problems such as cold welding, lamp tube leakage, and the inability to easily disassemble the lamp tube and wires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

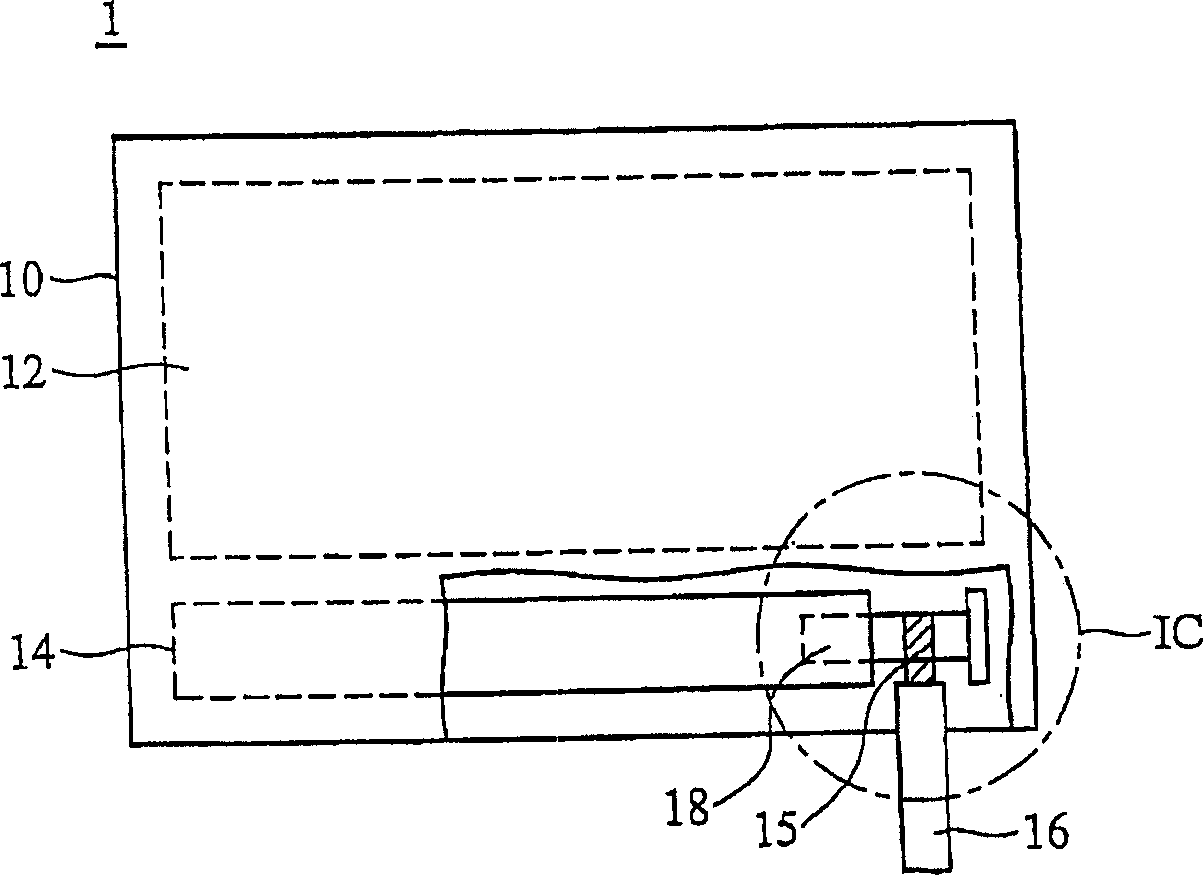

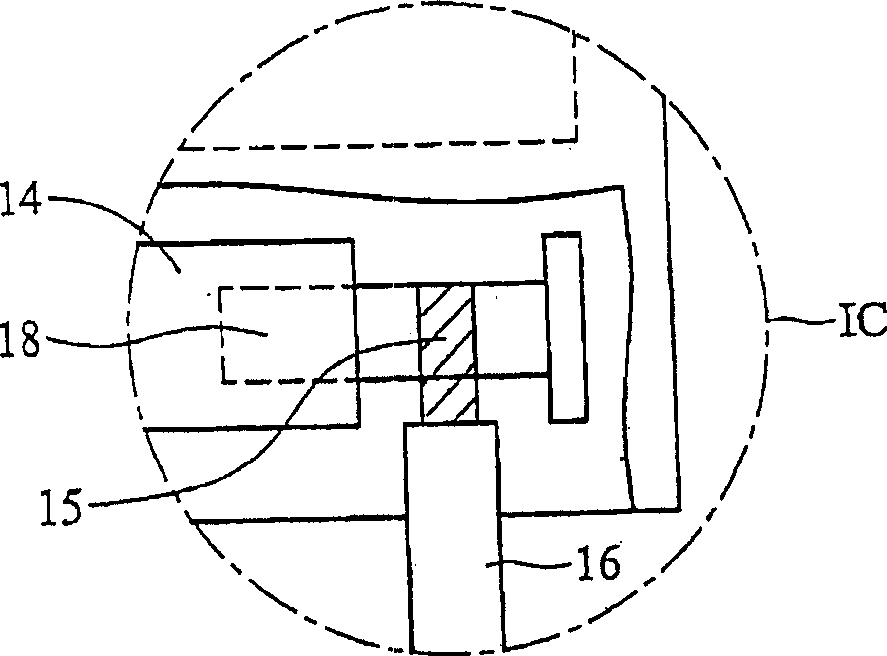

[0057] Figure 2A is an external perspective view showing a liquid crystal display 2 of the present invention, Figure 2B is based on Figure 2A A partially enlarged plan view of the lamp tube 24 and the wire 26 in the dotted line area IIB in . It should be noted that only one light tube 24 is shown in the figure as an example, and the present invention does not limit the quantity of the light tube 24 and the wires 26 .

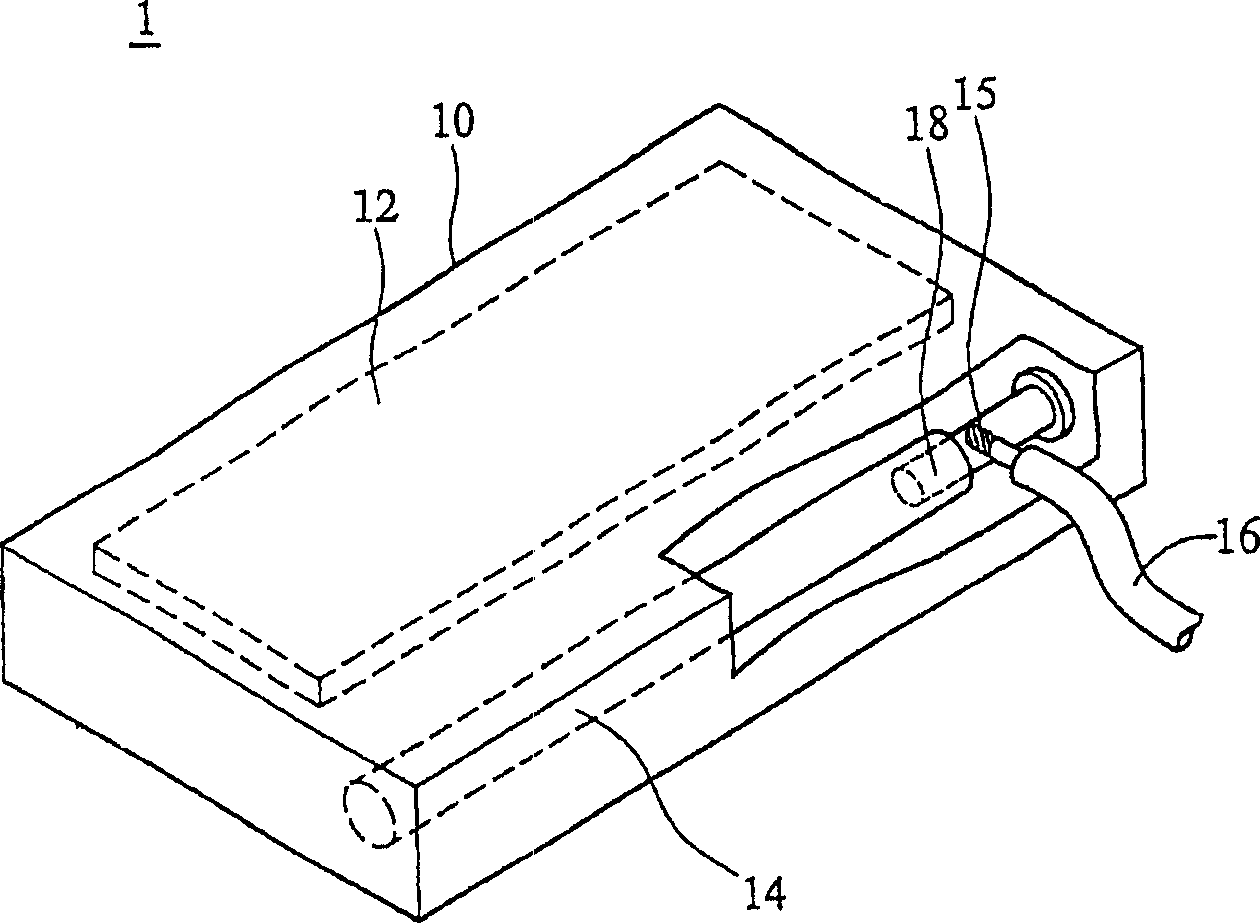

[0058] Such as Figure 2A As shown, the display 2 includes a housing 20, a panel 22, a lamp (light source) 24, an electrode 28, a wire 26, a first joint 23 and a second joint 25, the panel 12 and the lamp 14 are jointly arranged in the housing 10, wherein the lamp tube 24, the electrode 28 and the wire 26 form a detachable light source structure, such as Figure 2B shown. The first coupling part 23 is fixedly connected to the electrode 28 , and the second coupling part 25 is fixedly connected to the wire 26 . The electrode 28 is electrically connected t...

no. 2 example

[0064] Figure 3B It is a partially enlarged and exploded schematic view showing the lamp tube 24 and the wire 26 of the second embodiment. In this embodiment, the same parts as those of the first embodiment will not be repeated, but the difference is that: the first coupling member 23' has a groove 230', and the groove 230' has a threaded surface 231', In other words, the first coupling member 23' is like a nut with internal threads. The second coupling part 25' is a protruding part with a threaded surface 251', that is, the second coupling part 25' is a screw. The insulation component 29' is covered on the second combination part 25'. The insulating component 29' can be made of silica gel or other materials, which can protect the connecting structure of the first coupling part 23' and the second coupling part 25' to prevent electric leakage.

[0065] The connection method of the lamp tube 24' and the wire 26' of the second embodiment will be described below.

[0066] Bef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com