Fabricated wall and mounting process thereof

An installation process and assembly technology, which is applied in the direction of walls, formwork/formwork/work frame, formwork/formwork/work frame connectors, etc., can solve the problems of prefabricated wall panels such as heavy weight and space constraints. , to achieve the effect of high work efficiency, long service life and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

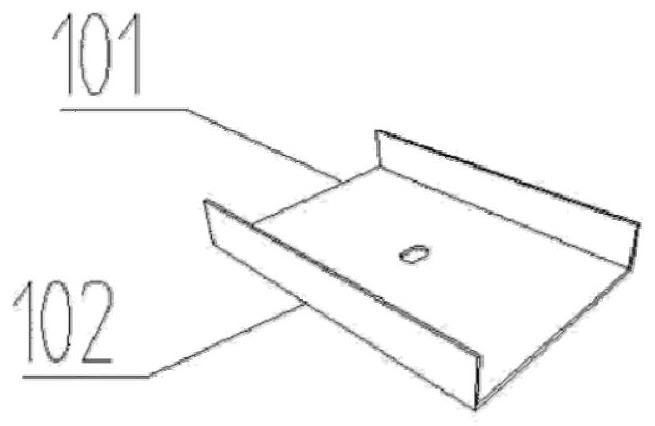

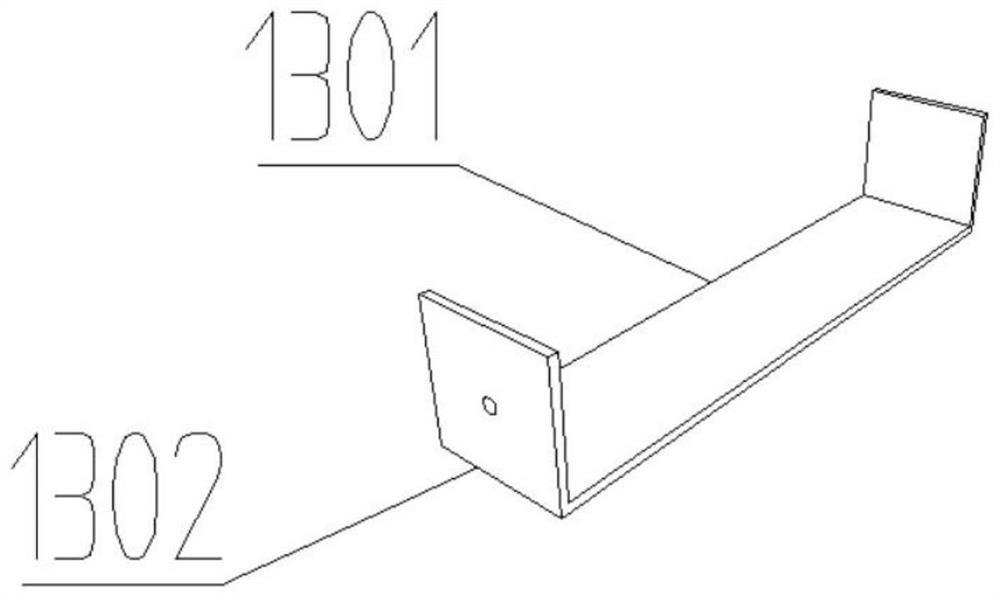

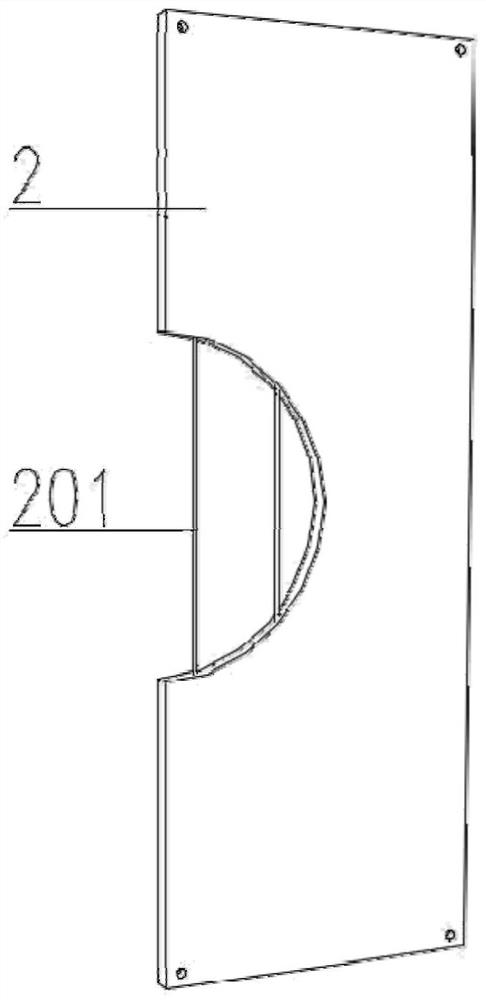

[0054]A prefabricated wall, such as Figure 1-14 As shown, it includes an assembly part 1, a prefabricated wall panel 2 and a formwork 10; the assembly part 1 is provided with an installation part 101 directly acting on the installation base surface, and a connecting part 102 directly acting on the prefabricated wall panel 2, in pairs The connecting parts 102 are arranged on opposite sides of the installation part 101; several of the assembly parts 1 are arranged along the length direction of the wall, and a plurality of the prefabricated wall panels 2 are matched with the corresponding connecting parts 102 and form opposite sides on both sides of the installation part 101. The two prefabricated base surfaces; the formwork 10 is arranged on the outer surfaces of the two adjacent prefabricated wall panels 2, the formwork 10 of the two prefabricated base surfaces is arranged oppositely, and the formwork 10 is provided with a number of connection holes, and the connection holes ar...

Embodiment 2

[0060] Embodiment 2 is a further improvement to Embodiment 1; further description, the same parts will not be repeated here, such as Figure 1-14 As shown, the spacing between two adjacent prefabricated wall panels 2 is equal in size, the spacing between two adjacent thermal insulation panels 5 is equal, and the spacing between adjacent thermal insulation panels 5 is greater than that of adjacent prefabricated wall panels. 2, the prefabricated wallboard 2 and the thermal insulation board 5 are formed with a filling column 8 with a cross-shaped cross-section.

Embodiment 3

[0062] A prefabricated wall installation process, such as Figure 1-14 shown, including the following steps:

[0063] Assembly installation: measure and set out on the installation base, and fix the installation part 101 of the assembly 1 on the installation base along the line;

[0064] Prefabricated wallboard installation: connect the prefabricated wallboard 2 with the connection part 102 on one side of the installation part 101, install the thermal insulation board 5 and / or the water, heating and electricity embedded 6 at the prefabricated wallboard 2, and connect the prefabricated wallboard 2 with the installation part 101 The connection part 102 on the other side is connected to form two opposite prefabricated base surfaces;

[0065] Formwork installation: a formwork 10 is arranged between two adjacent prefabricated wall panels 2, and the formwork 10 of the two prefabricated base surfaces is connected by a puller 11, so that the formwork 10 is connected to the prefabrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com