Economical longitudinal submerged arc welding X80 pipeline steel plate and production method

A technology of straight seam submerged arc welding and production method, which is applied in the field of X80 pipeline steel plate and production, can solve the problems of high cost, acid resistance, low strength level, etc. The effect of acid properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

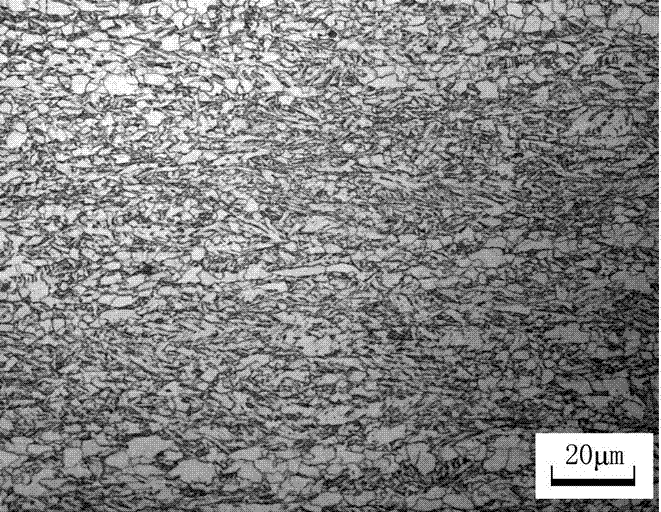

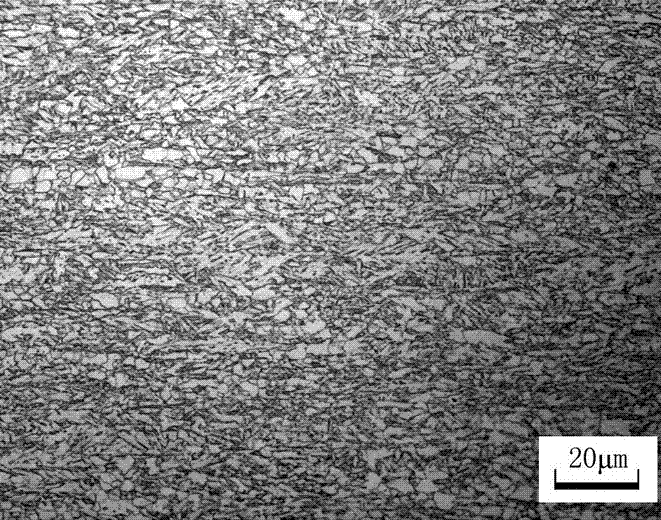

Image

Examples

Embodiment Construction

[0043] The present invention is described in detail below:

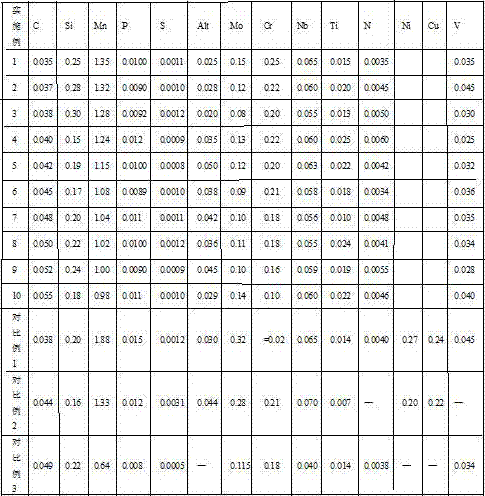

[0044] Table 1 is the chemical composition list of each embodiment of the present invention and comparative example;

[0045] Table 2 is the main process parameter list of each embodiment of the present invention and comparative example;

[0046] Table 3 is the horizontal main performance detection statistical table of each embodiment of the present invention and comparative example;

[0047] Table 4 each embodiment of the present invention and comparative example anti-HIC performance monitoring list;

[0048] Table 5 is the test list of anti-SSCC performance of each embodiment of the present invention and comparative examples.

[0049] Each embodiment of the present invention all produces according to the following steps:

[0050] 1) Continuous casting into slabs after converter and vacuum treatment; stack the slabs for slow cooling for no less than 24 hours;

[0051] 2) Heating the slab, controlling the heating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com