A Prefabricated Segmental Pier and Its Application in Bridge Construction

A bridge pier and segmental technology, which is applied to prefabricated segmental bridge piers and its application in bridge construction, can solve problems such as gaps between connecting rods and connecting holes, durability problems, and high maintenance costs, and reduce initial pouring defects , high bearing capacity and low construction risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

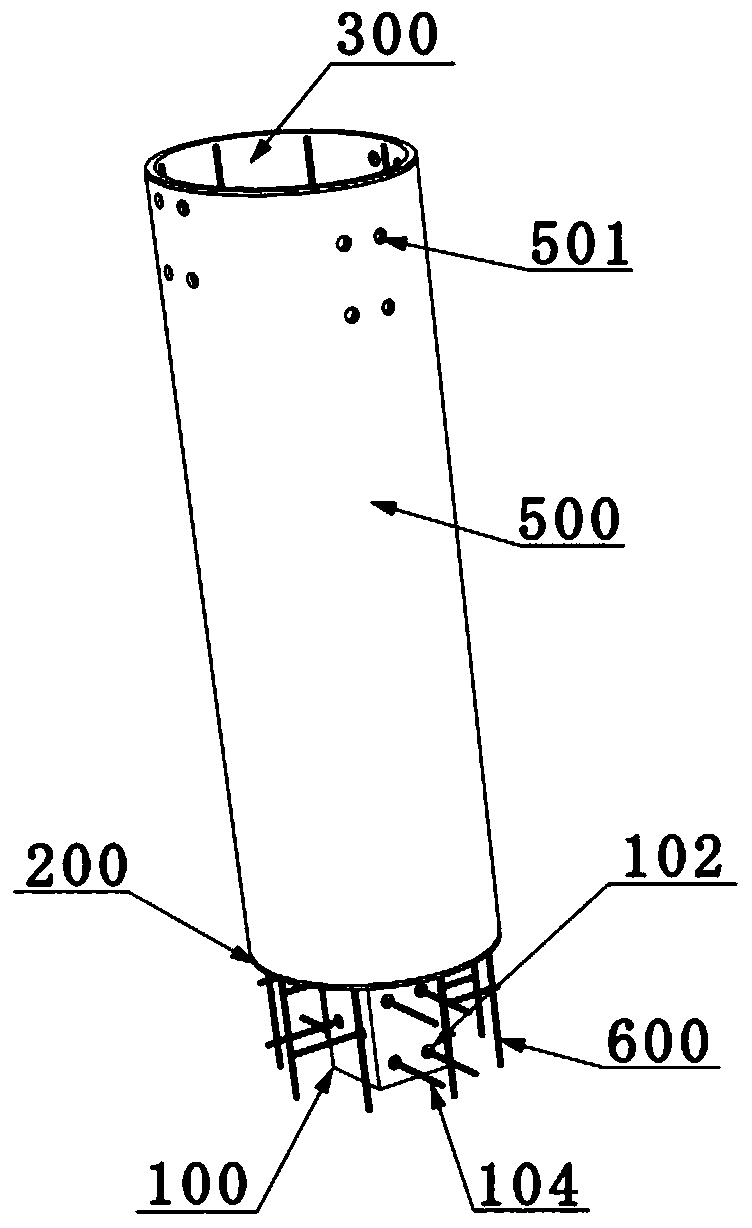

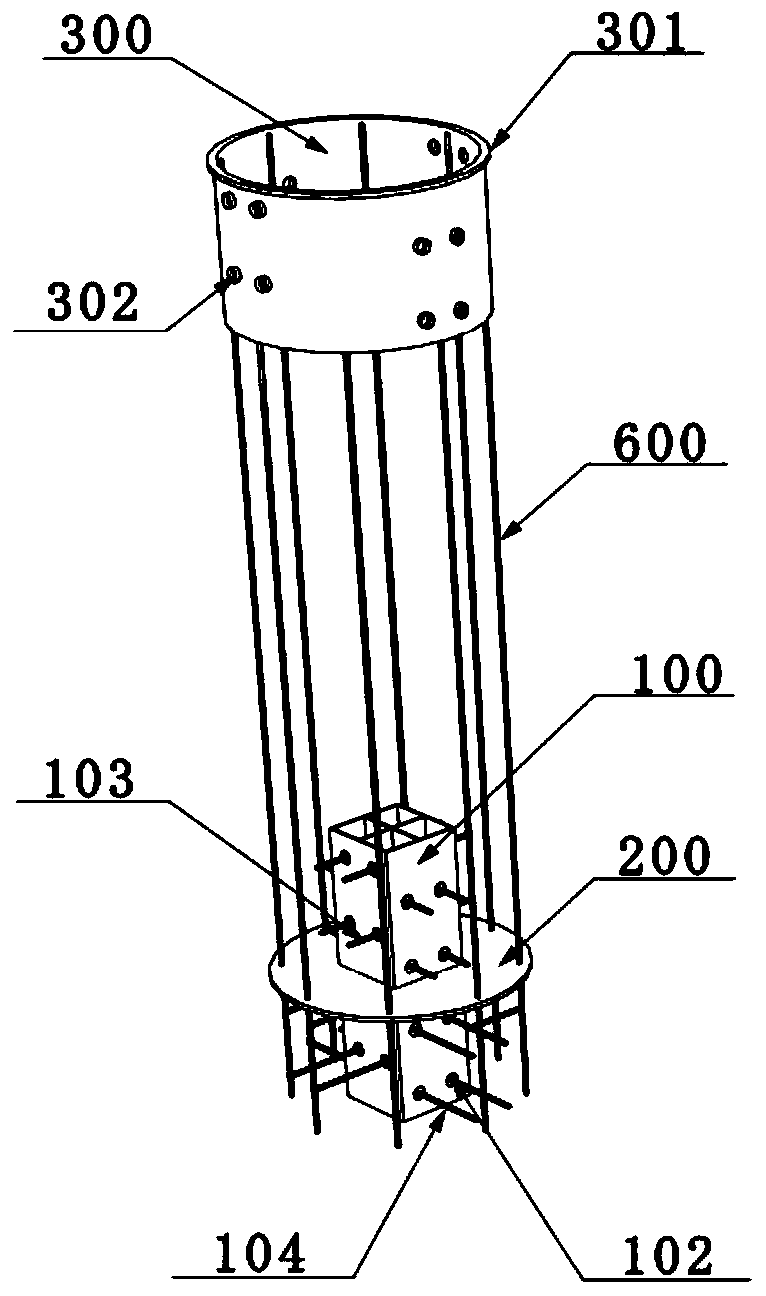

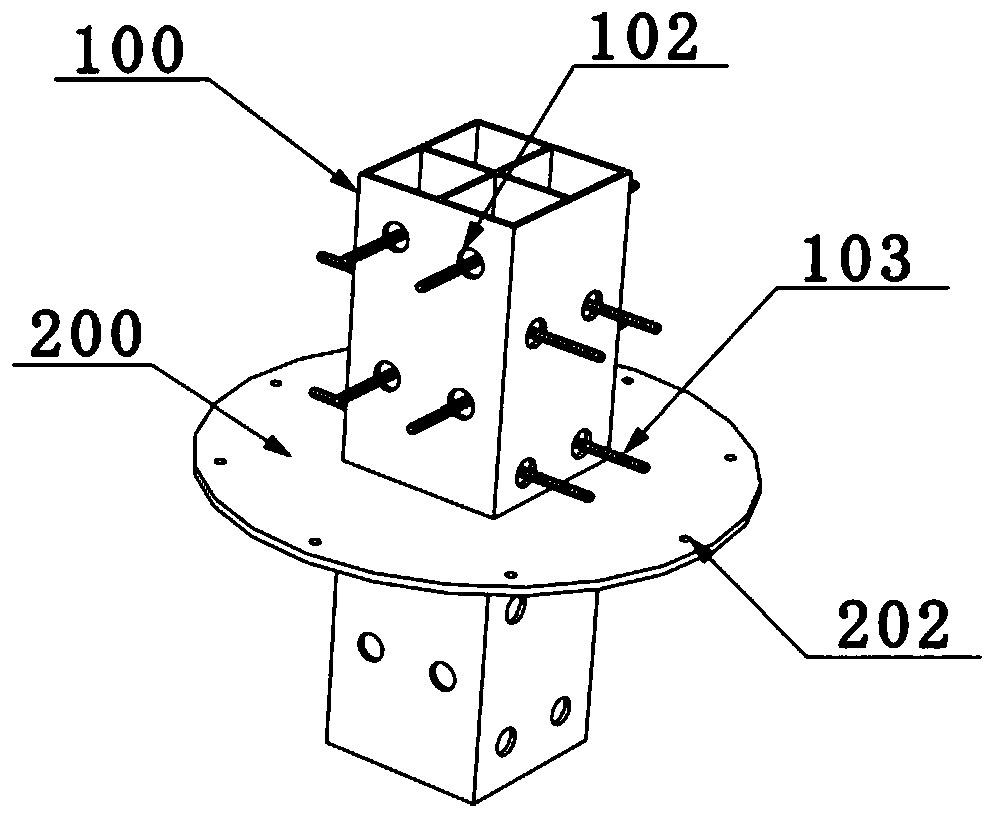

[0036] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0037] In the embodiment of the present invention, such as Figure 1-9 As shown, a prefabricated segmental pier is provided, and the prefabricated segmental pier includes a pier body 500 and a jacket 400 . Among them, the pier body 500 is a hollow or solid cement column, the overall shape is round or square, etc., and its specifications can be adjusted appropriately according to the construction requirements; in order to increase the supporting strength of the pier body, several longitudinal reinforcement ribs are arranged inside the pier body 500 600, the length of the longitudinal rib 600 is the same as the length of the pier body 500.

[0038] A steel liner 300 is installed at one end of the pier body 500. The steel liner 300 is barrel-shaped as a whole, and its cross-sectional shape is the same as that of the pier body 500. The wall t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com