Mechanical loading tool and method for outer grid wallboard

A technology of mechanical loading and wall panels, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve problems such as cracking, compression deformation, etc., and achieve the effects of avoiding vacuum bag damage, good force, and reducing manual operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

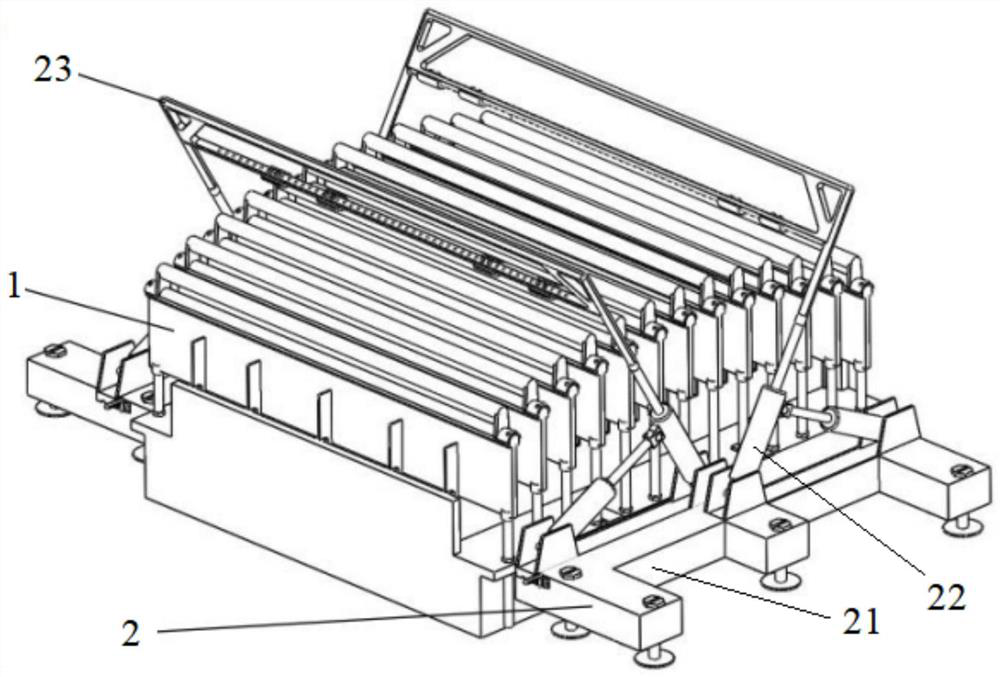

[0038] The present invention provides a mechanical loading tooling for outer grid wall panels, which includes a pallet mold 1 and a movable loading system 2; the movable loading system 2 is detachably arranged on the left and right sides of the pallet mold 1 and Above, it is used to complete the mechanical loading of the outer grid wall;

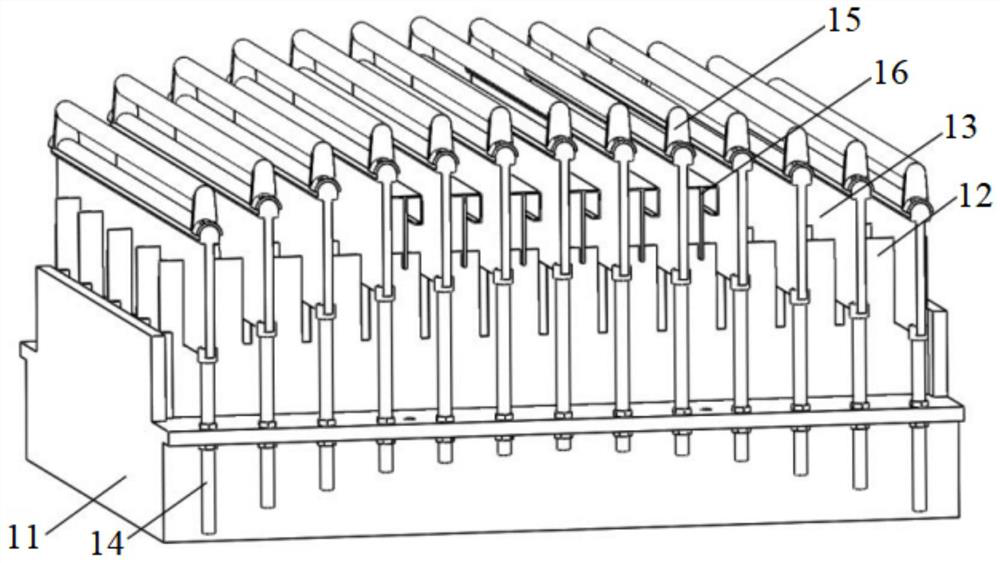

[0039] The pallet mold 1 includes a mold base 11, a horizontal clamp 13 that is directly or indirectly arranged on the mold base 11 and can be adjusted up and down, and a pressure plate 15 that is detachably arranged on the horizontal clamp 13;

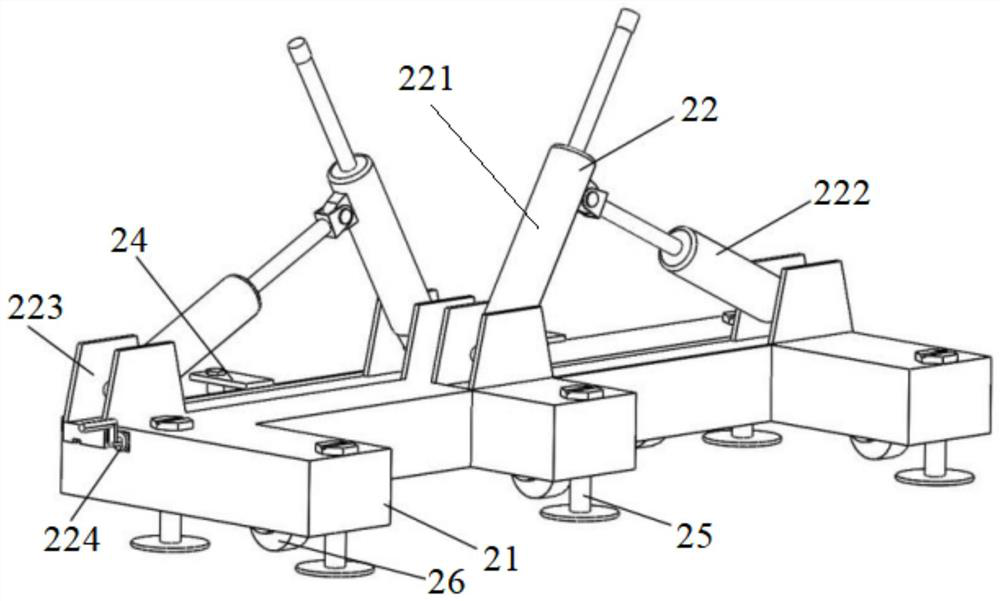

[0040] The movable loading system 2 includes a loading system base 21, a pressurizing movable assembly 22, a loading rod assembly 23 and a positioning connection structure 24;

[0041] The left and right sides of the pallet mold 1 are provided with loading system bases 21; the side of each loading system base 21 close to the pallet mold 1 is fixedly provided with a positioning connection structure 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com