Nylon composite material and preparation method thereof

A nylon composite material and raw material technology, applied in the field of polymer materials, can solve the problems of damage, easy cracking, insufficient strength and toughness of pure nylon, etc., and achieve the effect of low modification cost and low material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1a

[0050] A kind of preparation method of nylon composite material, comprises the steps:

[0051] Step1, stir 0.3 parts of lubricant TAF, 0.3 parts of EBS, 0.3 parts of antioxidant 1098, and 5 parts of processing aids to obtain mixing aids;

[0052] Step2, add 20 parts of PA66 and 25 parts of PA6 into a drying vertical mixer, stir and dry, add white oil accounting for 5% of the total mass of PA66 and PA6 to the dried PA66 and PA6, mix evenly, and then mix it with mixing aids stir;

[0053] Step3, 50 parts of mixed raw materials and chopped glass fiber are fed in the twin-screw extruder;

[0054] Step4, the mixed raw material and chopped glass fiber are fed from the second zone, the temperature of the second zone of the twin-screw extruder is set to 230°C, the temperature of the third zone is set to 240°C, the temperature of the fourth zone is set to 240°C, and the temperature of the fifth zone is set to 240°C, the temperature of the sixth zone is set to 220°C, the temperature of ...

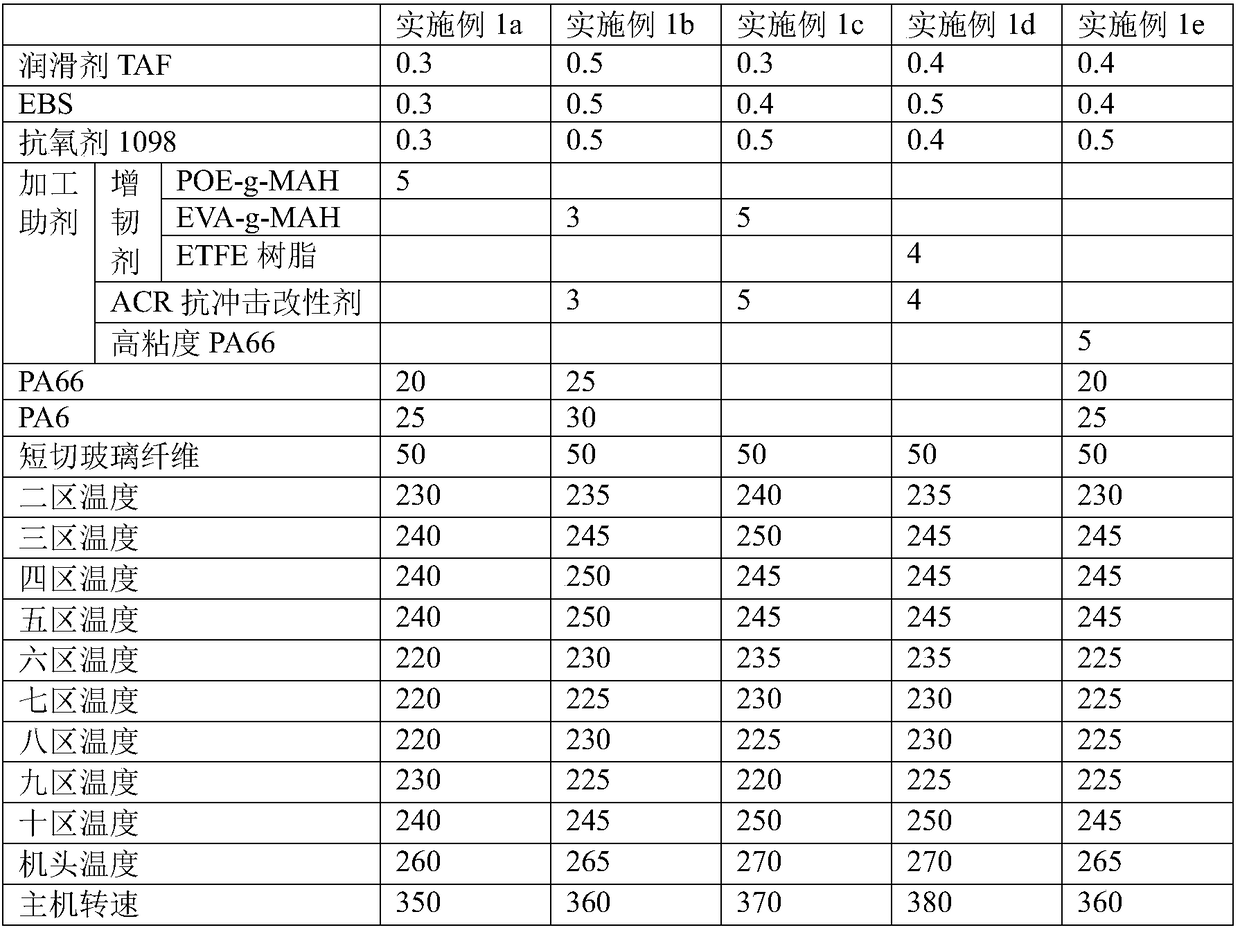

Embodiment 1b- Embodiment 1e

[0058] The preparation method of embodiment 1b-embodiment 1e is the same as embodiment 1a, and its difference only lies in the specific components of embodiment 1b-embodiment 1e and embodiment 1a, the specific component content and the temperature setting of each zone of the twin-screw extruder Different from the host speed, the specific components, specific component content and twin-screw extruder settings of embodiment 1b-embodiment 1e are shown in the following table:

[0059]

[0060] ACR impact modifier was purchased from Suzhou Amway Chemical Co., Ltd., and the production grade was ACR-201.

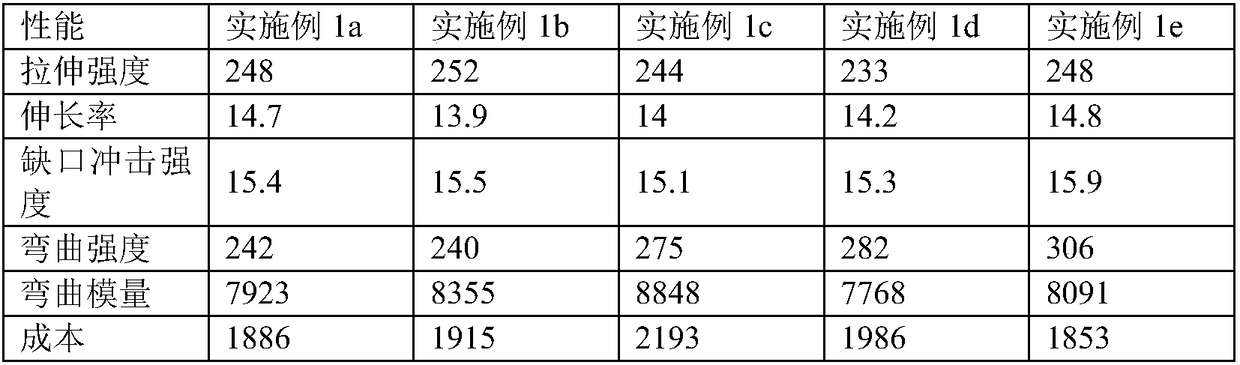

[0061] Plastic particles were prepared according to Example 1a-Example 1e, and their mechanical properties were tested.

[0062] According to "GB / T 1040.1-2006 Plastic Tensile Properties Test Method" for tensile strength test;

[0063] The elongation test is carried out according to "GB / T 1701-2001 Hard Rubber Tensile Strength and Determination of Elongation at Break";

[0064...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com