refrigerator

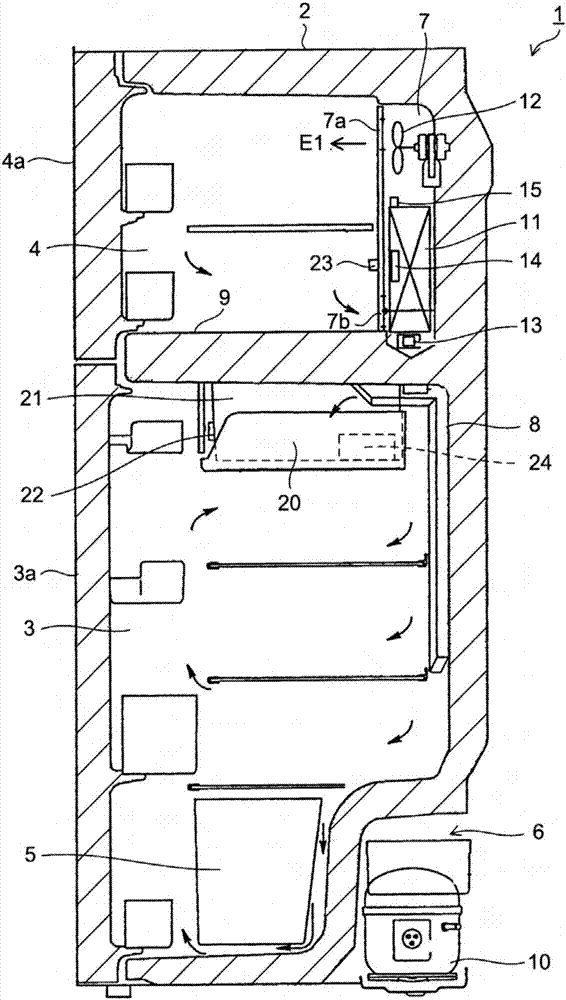

A refrigerator and evaporator technology, which is applied to cooling fluid circulation devices, defrosting, household appliances, etc., can solve the problems of inability to defrost and many frosts, and achieve the effect of suppressing abnormal heat generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

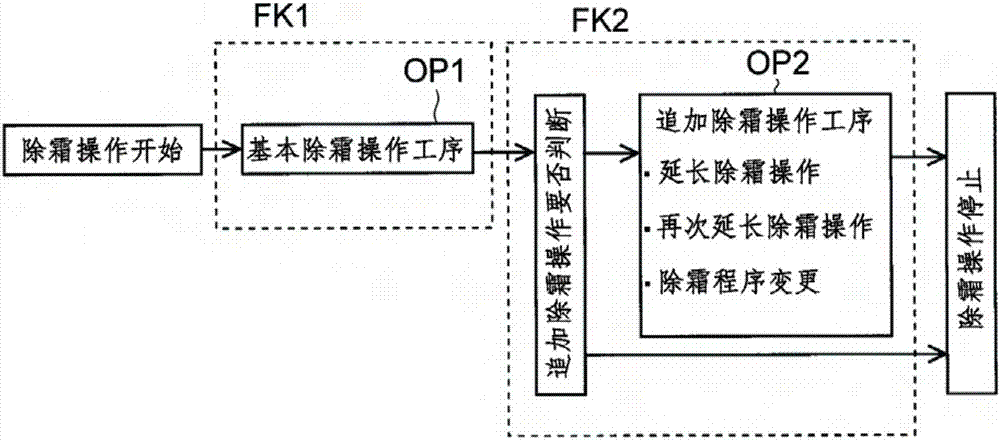

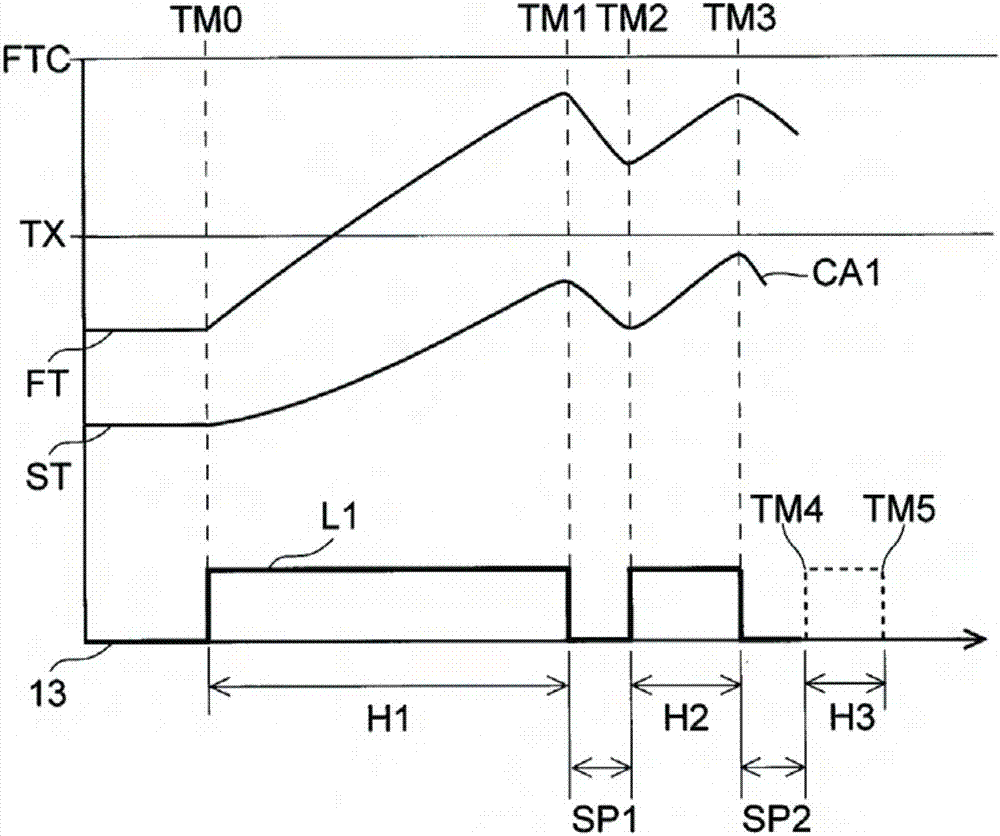

[0064] First, use Figure 4 The flow chart shown and Figure 5 The timing chart shown here is for explaining Example 1. Embodiment 1 relates to the first operation function, based on the temperature information that the temperature Te1 of the evaporator 11 detected at the first time (time TM1) after the start of the defrosting operation is lower than the second temperature TA, it is judged that additional defrosting is necessary operation, and drive the defrosting device 13 again. also, Figure 5 0 shown on the vertical axis of , indicates the position of the temperature 0°C, and the first temperature TX is set at 0°C or higher.

[0065] If the defrosting operation starts, the basic defrosting operation of step S1 starts (time TM0). Next, in step S2, it is judged whether the driving duration has reached the first time (time TM1), and when it is judged that the first time has been reached, it advances in the Y direction, and the basic defrosting operation stops (step S4). ...

Embodiment 2

[0078] Next, use Figure 6 The flow chart shown and Figure 7 In the timing diagram shown, the embodiment related to the second operation function will be described as Embodiment 2. The above-mentioned second operation function judges the need for evaporator 11 based on the temperature information that the temperature of the evaporator 11 drops after reaching the first time (time TM1). Perform additional defrosting operation and perform drive again. Since the initial process corresponding to the basic defrosting operation process is the same as that of Embodiment 1, the description is omitted, Figure 6 Only the additional defrosting operation steps from step S5 to step S8 are shown.

[0079] In the present embodiment, after the basic defrosting operation is stopped (step S4), the temperature Te1 of the evaporator 11 at time TM1 is stored (step S5A). Next, proceed to step S5B, compare the temperature Te2 at time TM2 after a predetermined time has elapsed, that is, after the...

Embodiment 3

[0090] Next, use Figure 8 The flow chart shown and Figure 9 In the timing diagram shown, the following example will be described as Example 3. When the temperature information indicating that the frost has not completely melted at the end of the extended defrosting operation is detected, it is judged that it is necessary to perform an additional defrosting operation and extend it again. Defrost operation. Figure 8 Only the additional defrosting operation process from the extended defrosting operation of step S6 to the normal control of step S8 is shown.

[0091] After the extended defrosting operation of step S6 starts, in step S6A, judge whether the temperature Te of evaporator is more than the first temperature TX, if " yes ", then advance to Y direction, make extended defrosting operation stop (step S7 ) and return to normal control (step S8).

[0092] If it is "NO" in step S6A, it advances in the N direction, and it is judged whether the drive duration has reached th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com