Potato planting equipment

A potato and equipment technology, applied in the field of potato planting equipment, can solve problems such as unusable and large size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

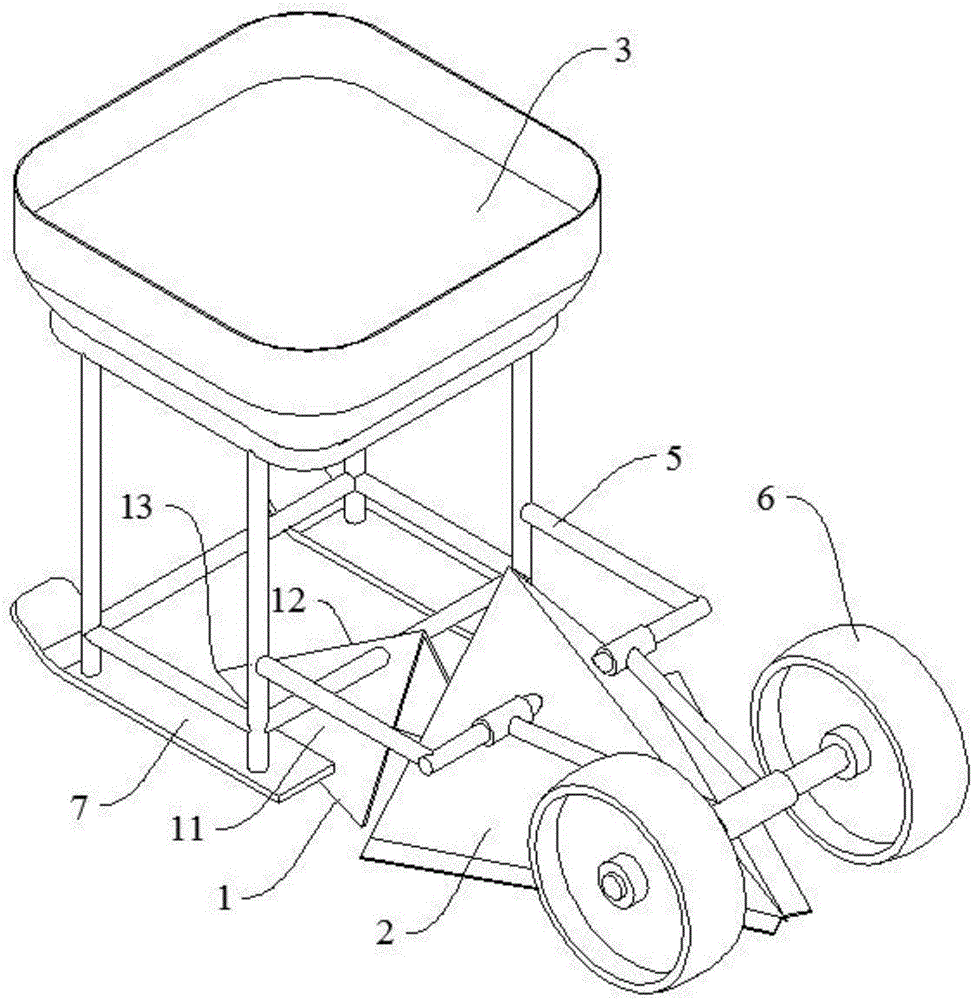

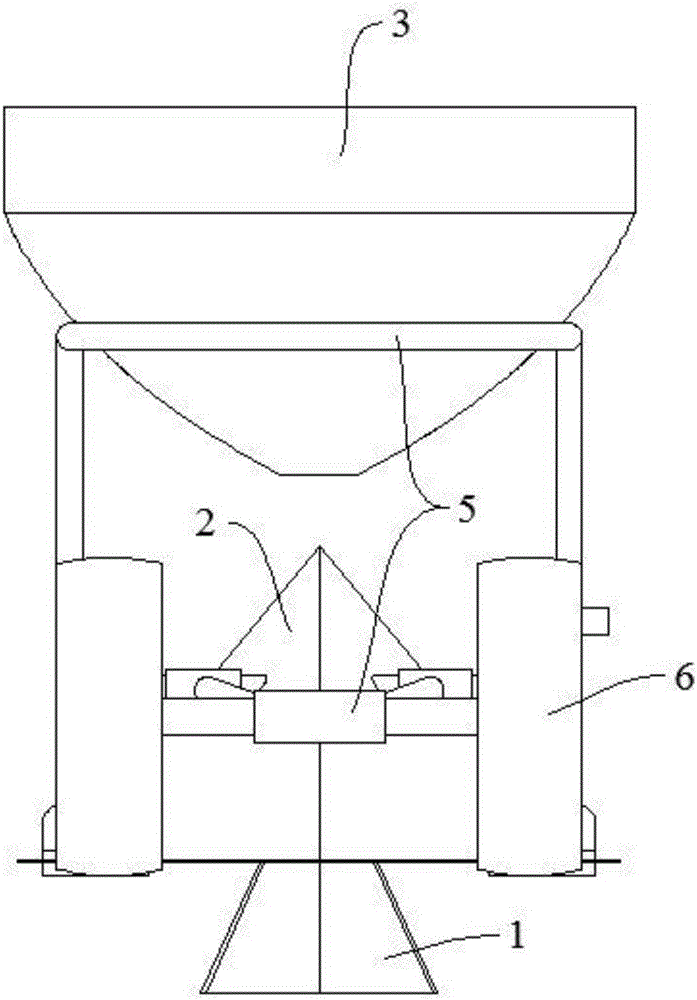

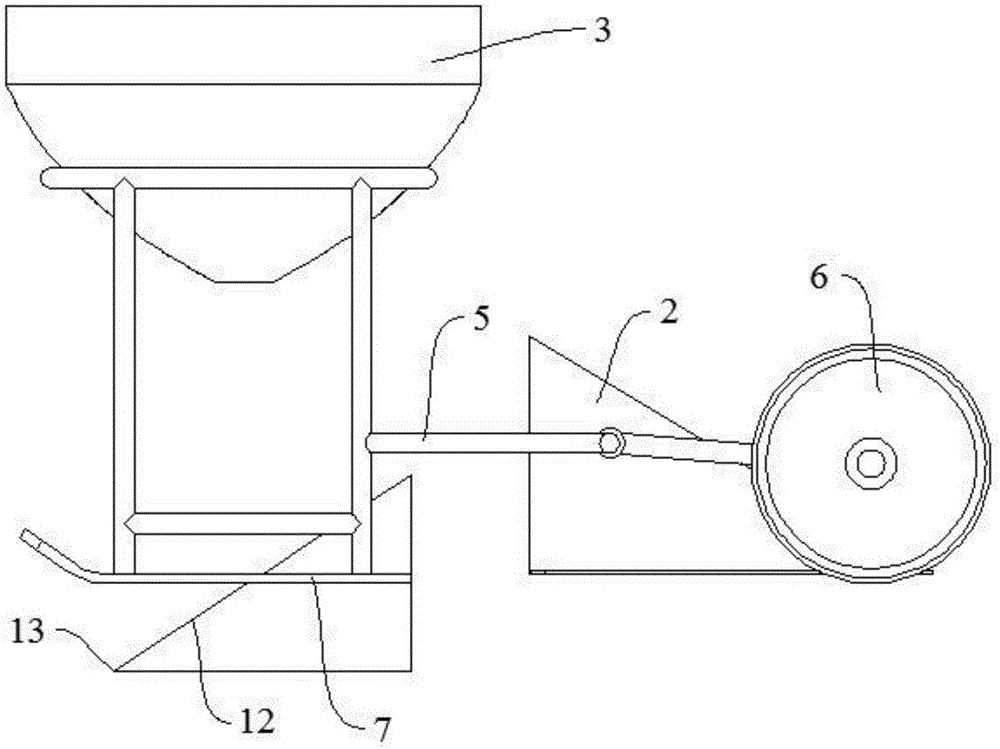

[0016] Such as Figure 1 ~ Figure 4 Shown, a kind of potato planting equipment comprises: breaking soil mechanism 1, covering soil mechanism 2, seed potato box 3, blanking mechanism 4, frame 5, walking wheel 6, slide plate 7; Wherein, breaking mechanism 1 has two Inclined surface 11, the intersection of the two inclined surfaces 11 forms a soil-breaking blade ridge 12, and the blade ridge 12 extends obliquely downward to the blade tip 13. When planting, the blade tip 13 of the soil-breaking mechanism 1 is located in the soil layer , and the depth is consistent with the depth required for planting potatoes, the soil layer is broken through the blade tip 13 and the blade ridge 12, and then the soil is pushed away to both sides through the inclined surface 11, thereby forming the ditch required for planting potatoes, breaking the soil The mechanism 1 is fixed to the frame 5, the frame 5 is fixed on the slide plate 7, the slide plates 7 are respectively located on both sides of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com