A method and system for comprehensive utilization of dry separation of bauxite

A bauxite and dry separation technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the pollution of groundwater resources, reduce the production capacity of a single machine of equipment, and provide no technical solutions or inspiration for separation or screening, etc. problems, to achieve the effect of protecting and rationally utilizing land resources, preventing and controlling soil erosion, and enhancing the production capacity of a single machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

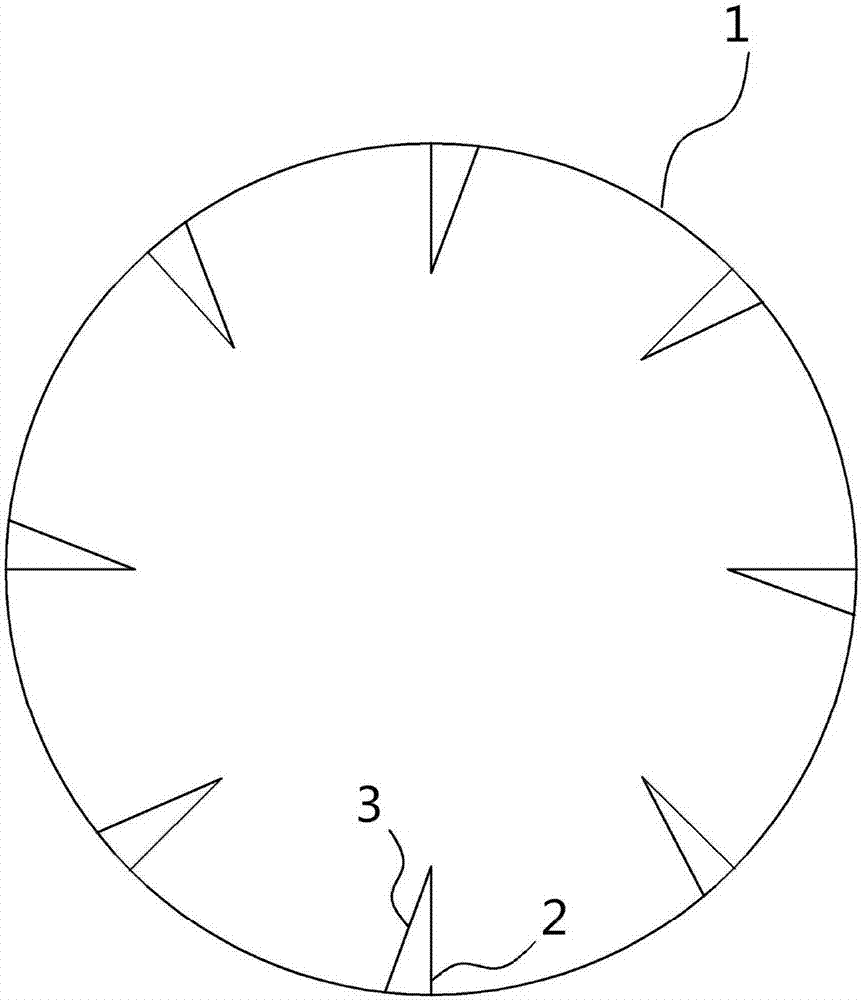

[0051] Such as figure 2 As shown, the side view of the lifting plate in the drum dryer in the present invention, the grid plate 2 is vertically arranged on the inner wall 1 of the drum dryer along the axial direction, and the grid plates 2 are symmetrically distributed, and the specific number can be determined according to the actual situation , such as 4, 6 or 8, in this embodiment, 8 grid plates are arranged on the inner wall, which can be fixed on the inner wall by welding.

[0052] The grid plate 2 is welded and fixed on the inner wall alone, and its strength has certain limitations. When the drum dryer is running, the mineral material inside will have a strong impact on the grid plate 2. In some cases, the grid plate 2 may be easily damaged. Crooked or even separated from the inner wall, so a support plate 3 is provided on one side of the grille plate 2. The support plate 3 is also in the shape of a grid. The support plate 3 obliquely connects one end of the grille plat...

Embodiment 2

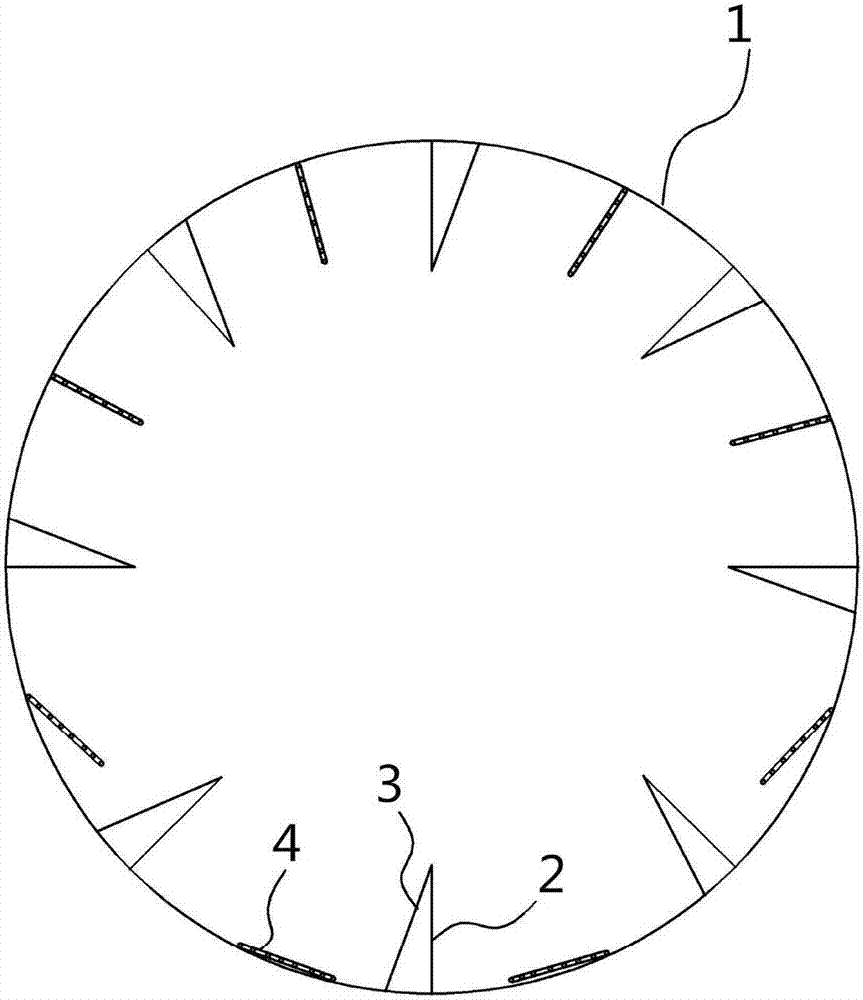

[0056] Such as image 3 Shown, present embodiment has increased chain 4 on the basis of embodiment 1.

[0057] The chain 4 is set between the lifting plates, and the two ends of the chain 4 are set on the inner wall along the axial direction of the drum dryer. There is a gap between the chain 4 and the inner wall, and the gap is smaller than the height of the grid plate.

[0058] When the drum dryer is running, the cylinder is rotating, and the chains inside are also rotating. The states of the chains at different positions are also different. For example, the chains at the bottom of the cylinder are freely scattered on the inner wall, and the chains at the top of the cylinder It is in a tight vertical state, and other positions are in between these two states. When the chain at the top falls to the bottom with the cylinder, the chain gradually transitions from a tight state to a loose state, and it will hit the inner wall , hitting near the angle between the grill plate and ...

Embodiment 3

[0062] In this example, the raw ore is selected from a bauxite mining area in Jingxi County, Baise City, Guangxi.

[0063] The grade and basic data of the raw ore are as follows:

[0064] The mud content is 40%, the moisture content is 24%, Al 2 o 3 60.42%, SiO 2 12.32%, Fe 2 o 3 14.1%, TiO 2 It is 4.9%, and the above-mentioned data are all mass fractions, and are the average number of sampling analysis test.

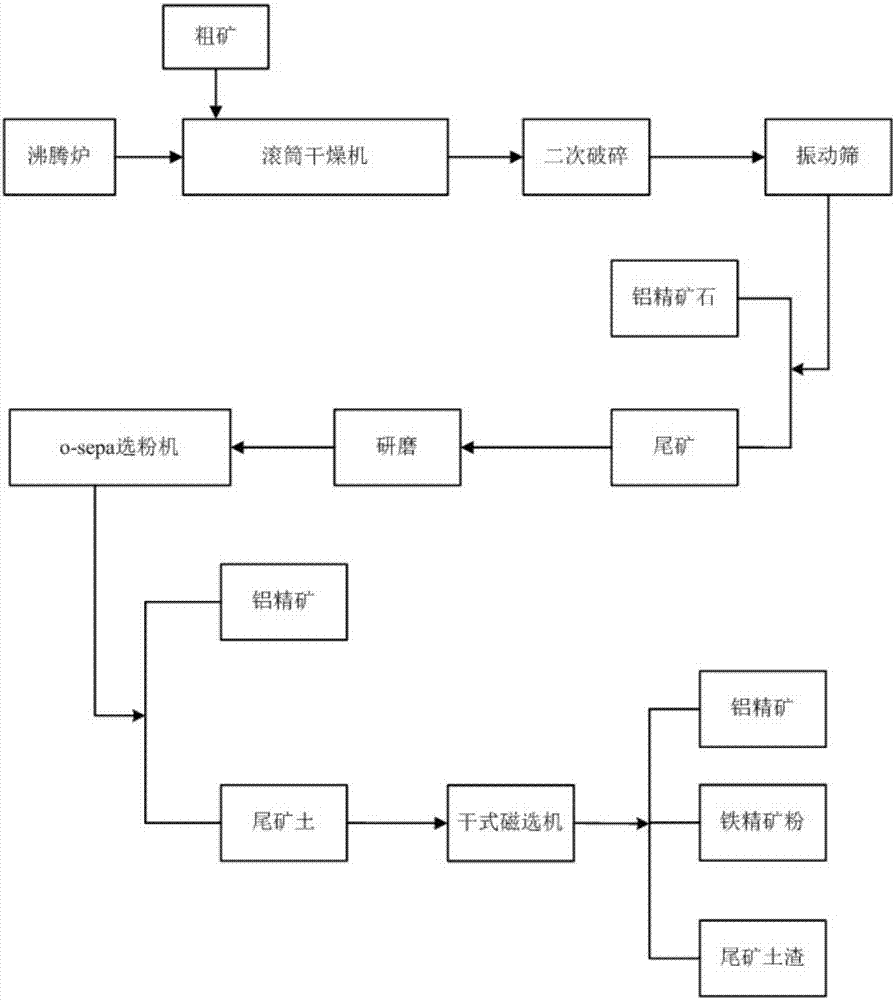

[0065] figure 1 In order to summarize the method of comprehensive utilization of dry selection in the summary of the invention in the form of a flow chart, it is easy to understand.

[0066] After repeated experiments, we found that the aluminum-silicon ratio changes with the particle size: the finer the particle size, the lower the aluminum-silicon ratio. At +0.5mm particle size, the aluminum-silicon ratio is greater than 7. When the silicon ratio is less than 2, silicon is enriched at the fine particle level. Therefore, as long as the -0.5mm to -0.2mm particl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com