Machining method for intermittent circular-arc oil cavity of static pressure nut

A technology of intermittent arcs and processing methods, which is applied to transmission devices, belts/chains/gears, mechanical equipment, etc., can solve problems such as high cost, complicated process, and affecting the accuracy of thread transmission, so as to reduce processing costs and simplify processing Process, the effect of ensuring transmission accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

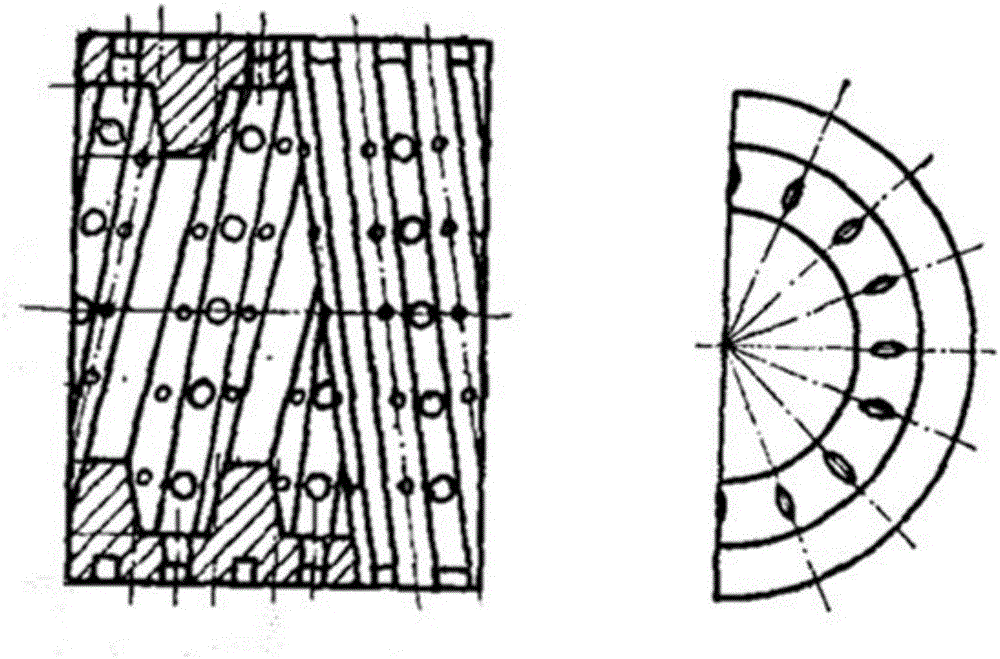

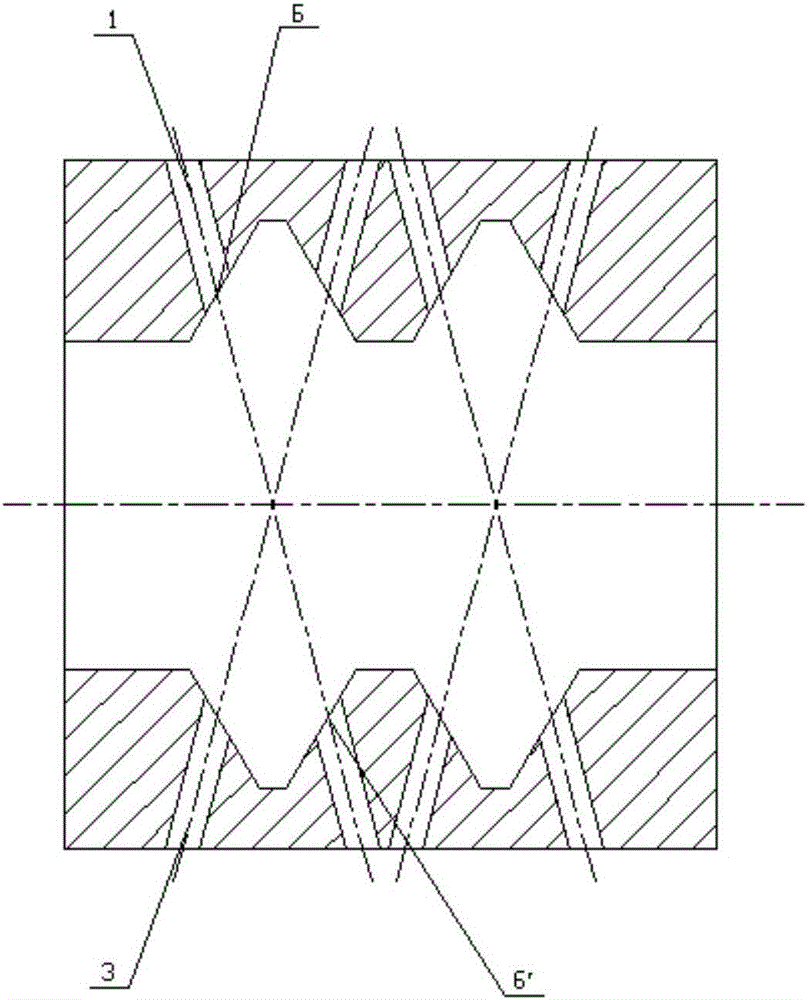

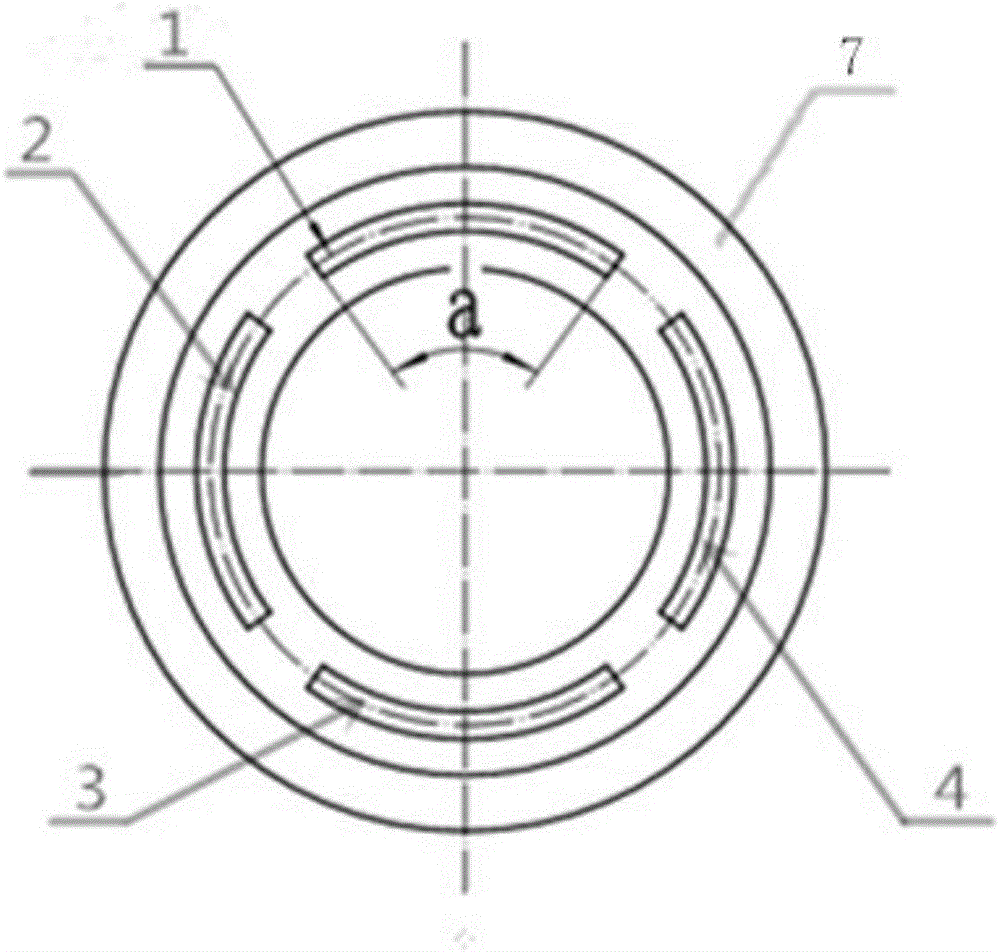

[0041] The first embodiment of the processing method of the hydrostatic nut intermittent arc oil chamber of the present invention, as Figure 2 to Figure 5 shown, including:

[0042] Step 1: Drill the first hole 5 and the second hole 5' on the relative position of the outer circle of the static pressure nut;

[0043] Step 2: thread the cutting line in the first hole 5 and the second hole 5';

[0044] Step 3: Cut out the outline and width of one side of the intermittent arc oil chamber 1 on the static pressure nut 7 and the outline and width of the other side in sequence;

[0045] Step 4: Exit the cutting line from the first hole 5 and the second hole 5', and the intermittent arc oil chamber 1-1' is finished.

[0046] Intermittent circular arc oil chambers 2-2', 3-3' and 4-4' can be produced respectively by the above-mentioned method.

[0047] In the first embodiment of the method for processing the intermittent arc oil cavity of the static pressure nut of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com