Automatic packing machine

A technology of automatic and rotary drive mechanism, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of time-consuming, labor-intensive, low-efficiency, etc., and achieve the effect of wide application, strong practicability, and speeding up the sealing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

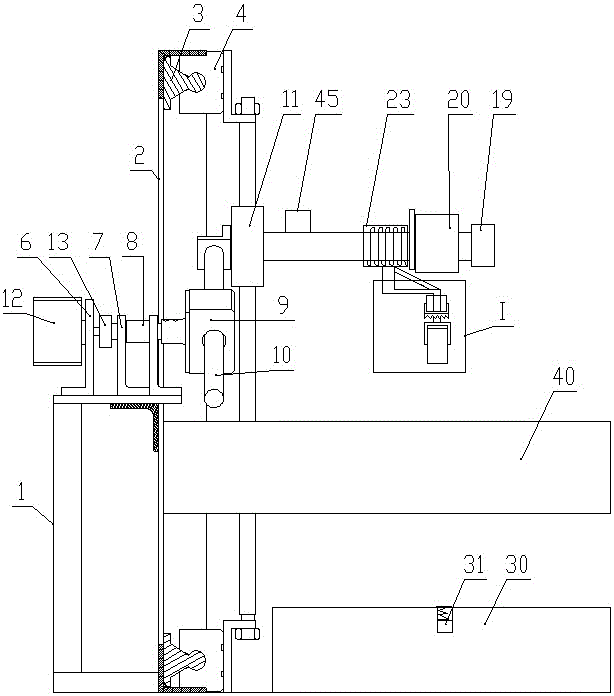

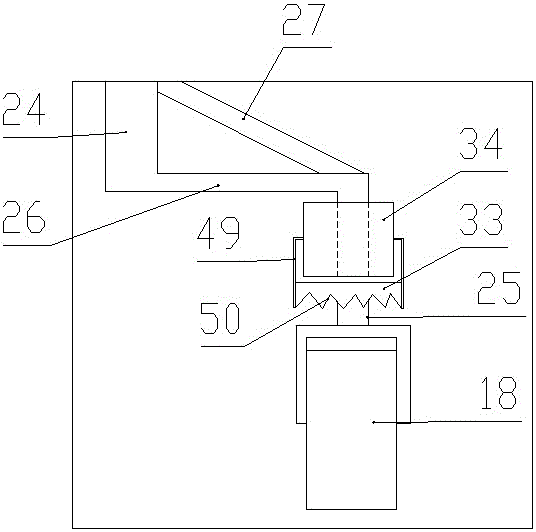

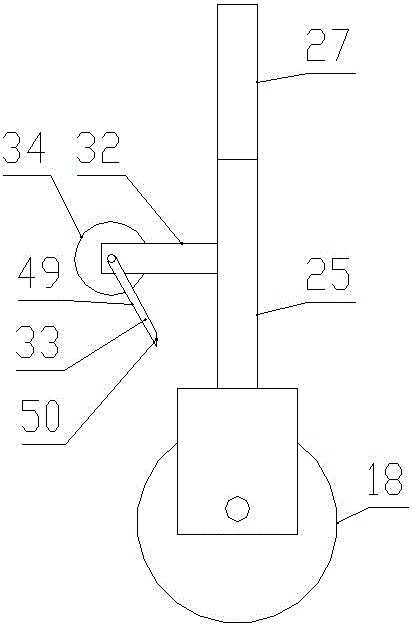

[0022] Such as Figure 1-5 as shown in front of figure 1 The angle of view is the left direction of this embodiment, figure 1 The right side of is forward, figure 1 The left side is backward, and the automatic packing machine of the present invention comprises frame 1, base 30 and rotary drive mechanism, and rotary drive mechanism is positioned on frame 1, and frame 1 front side is fixedly provided with the installation frame that external shape is rectangular 2. The height of the installation frame 2 is greater than the height of the frame 1. A baffle 40 is fixed on the right edge of the installation frame 2. The base 30 is arranged on the bottom front side of the installation frame 2. The micro switch 31 on the upper surface, the front side of the upper edge and the lower edge of the installation frame 2 are all provided with a first slide rail 3 located in the horizontal direction, and each first slide rail 3 is slidably connected with a first slide rail 3. Slider 4, two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com