A hybrid hydrogel based on chemical crosslinking of polyester nanoparticles and its preparation method and application

A nanoparticle and hydrogel technology, which is applied in the field of hybrid hydrogel and its preparation, can solve the problems of difficult chemical cross-linking formation and less active groups, and achieve good biodegradability and biocompatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

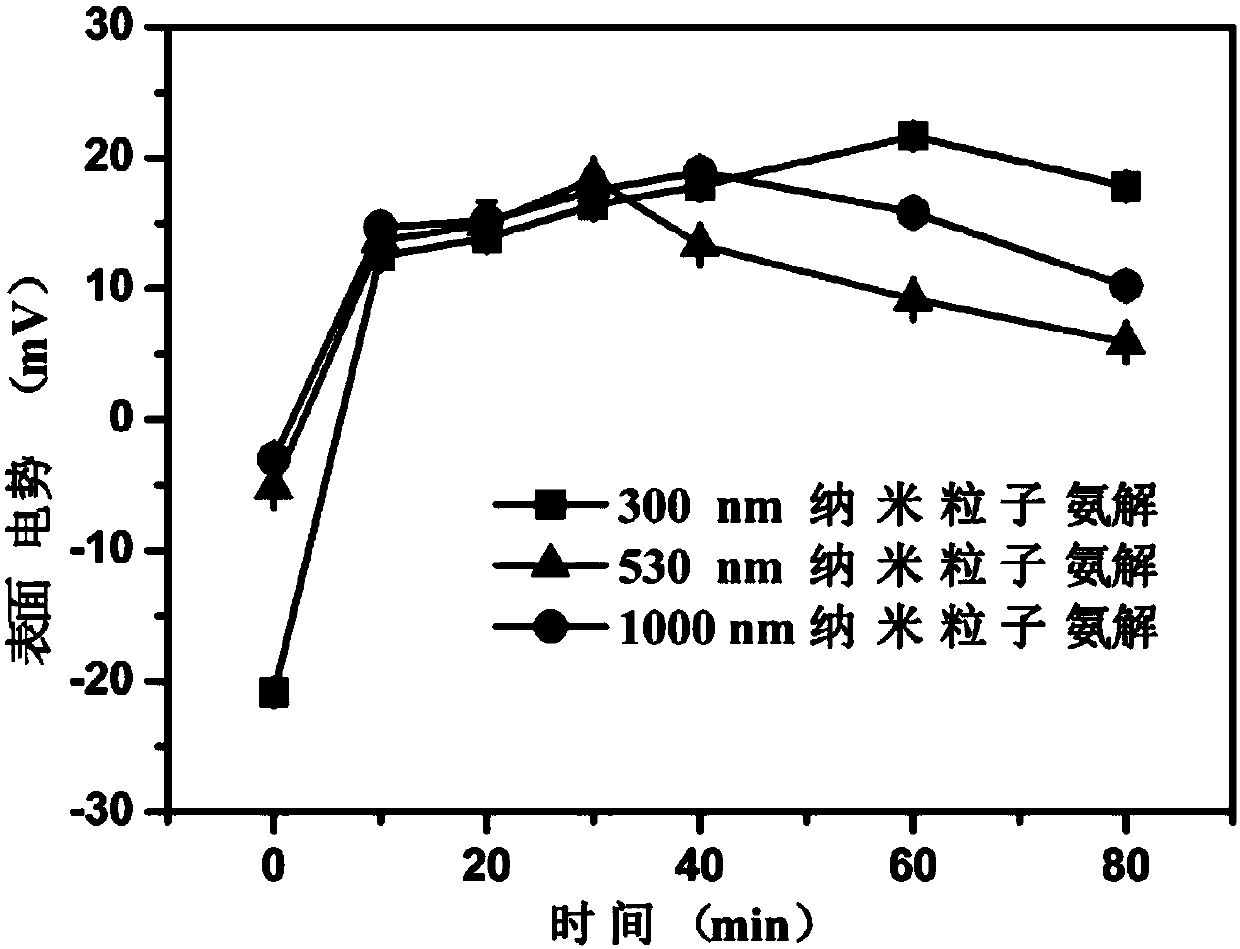

[0063] Example 1. Changes in the surface potential of nanoparticles at different treatment times

[0064] Follow the steps below to prepare ammonia-treated nanoparticles:

[0065] (1) Dissolve branched polyethyleneimine (b-PEI, molecular weight 1200) in a 1:1 mixed solvent of ethanol and water to form a b-PEI solution with a concentration of 20mM;

[0066] (2) Disperse PLGA (molecular weight 100,000) nanoparticles with particle diameters of 300 nm, 530 nm and 1000 nm into the b-PEI solution prepared in step (1) to obtain a suspension with a mass concentration of 5 mg / mL;

[0067] (3) After sonicating the suspension prepared in step (2) at 100 W for 10 min, 20 min, 30 min, 40 min, 60 min and 80 min, the suspension was centrifuged at a speed of 11000 r / min for 8 min to collect the product. The resulting product was washed 3 times with water and freeze-dried.

[0068] (4) The nanoparticles prepared in step (3) with different aminolysis treatment times are prepared into suspensions of the ...

Embodiment 2

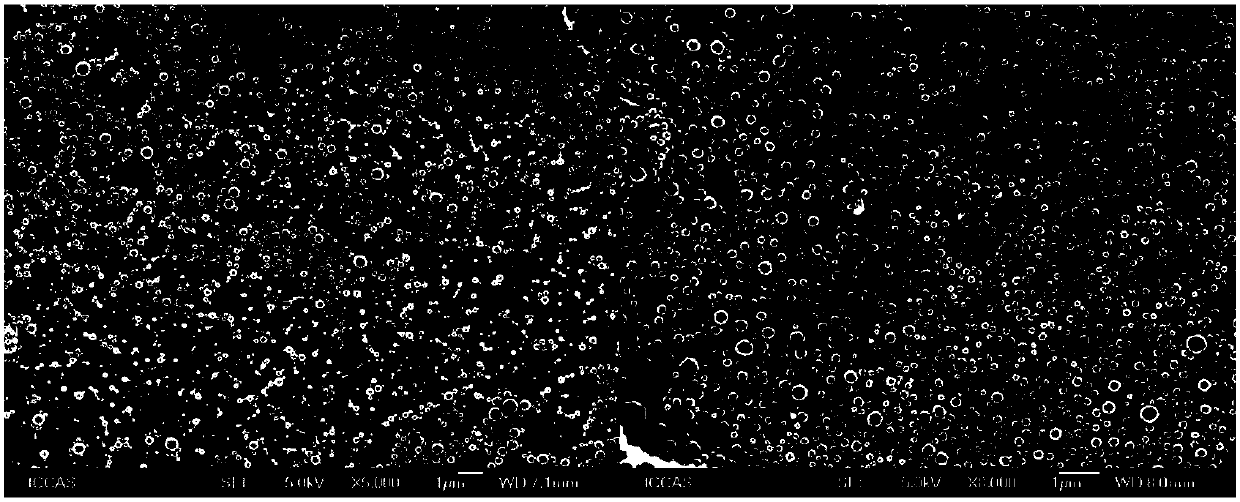

[0079] Example 2. Preparation of hybrid hydrogel

[0080] (1) Disperse the aminolysis nanoparticles (with a particle size of 300nm) obtained in Example 1 after aminolysis for 60 minutes in deionized water, and add an equal volume of four-arm star polyethylene glycol succinate (4-arm- PEG-SC, molecular weight 10k) polymer aqueous solution, so that the solid content of the nanoparticles is 2.5%, and the mass percentage concentration of the polymer is 2.5%.

[0081] (2) Vortex the mixture obtained in step (1) to obtain a hydrogel;

[0082] (3) freeze-dry the hydrogel prepared in step (2), and analyze by SEM.

[0083] The scanning electron micrograph of the hybrid hydrogel prepared in this example is as follows Image 6 Shown.

Embodiment 3

[0084] Example 3. Preparation of hybrid hydrogel

[0085] (1) Disperse the nanoparticles (with a particle size of 300 nm) obtained by aminolysis in Example 1 for 60 minutes in deionized water, and add an equal volume of four-arm star polyethylene glycol succinate (4-arm-PEG- SC, the molecular weight is 10k) polymer aqueous solution, so that the solid content of the nanoparticles is 7.5%, and the mass percentage concentration of the polymer is 2.5%.

[0086] (2) Vortex the mixture obtained in step (1) to obtain a hydrogel;

[0087] (3) freeze-dry the hydrogel prepared in step (2), and analyze by SEM.

[0088] The scanning electron micrograph of the hybrid hydrogel prepared in this example is as follows Figure 7 Shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap