Dual-drive automatic tube penetrating machine and method

A technology of automatic pipe threading machine and driving mechanism, which is applied to bridge parts, erecting/assembling bridges, bridges, etc. It can solve the problems of insufficient clamping force of the transmission sleeve, insufficient overall driving force, slipping of rubber rods, etc., and achieves a small number , The performance is safe and reliable, and the effect of preventing lateral slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

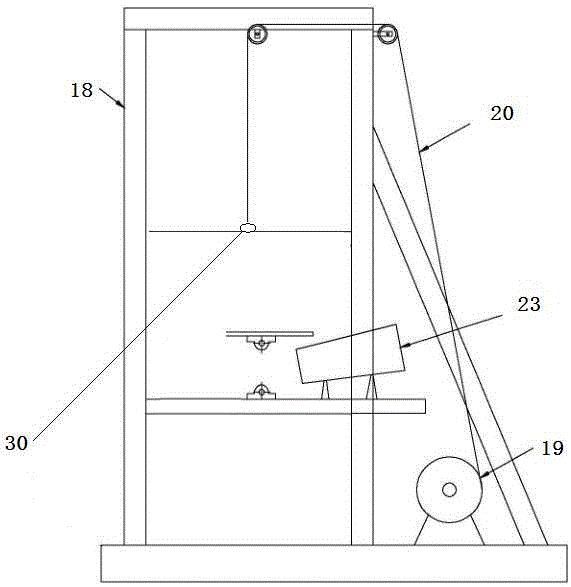

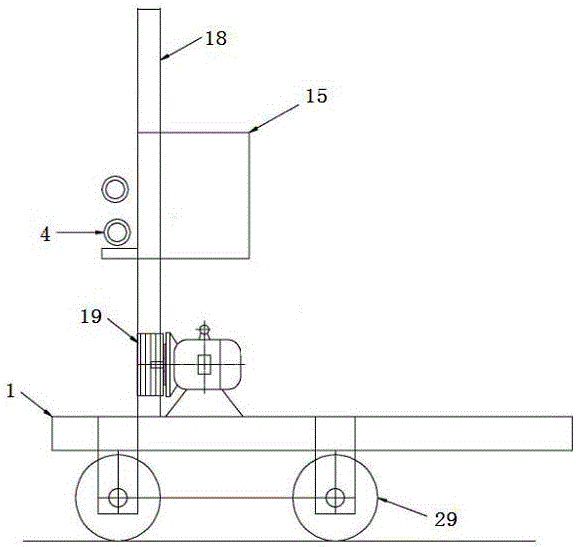

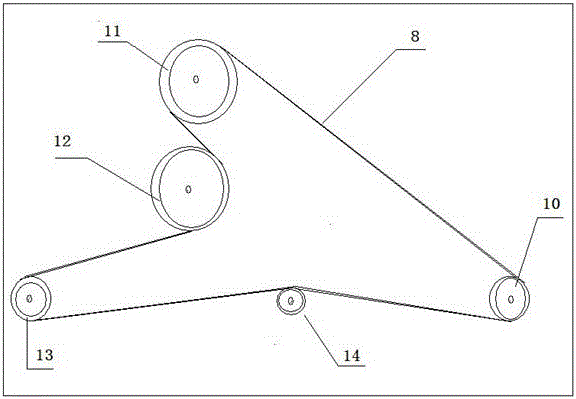

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0032] As shown in the figure, a double-drive automatic pipe threading machine provided by the present invention includes a support 1, a driving mechanism and a steel chuck 2, including an upper driving wheel 3 and a lower driving wheel 4, and an upper driving wheel 3 and a lower driving wheel 4. The upper and lower driving wheels are opposite and the axial directions are on the same vertical plane. The middle part of the upper driving wheel 3 and the lower driving wheel 4 has a concave arc 5. The two concave arcs are used to accommodate and clamp rubber rods. The driving motor drives the upper driving wheel 3 and the lower driving wheel 4 rotate simultaneously in the opposite direction. The steel chuck 2 is installed on the front end of the rubber rod. The lower part of the steel chuck 2 is provided with a roller 6 and a telescopic support ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com