Automatic gear shifting system for gearbox

A technology for automatic shifting and gearboxes, applied in the direction of transmission control, components with teeth, belts/chains/gears, etc., which can solve problems such as huge maintenance costs and complicated wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the above and / or other purposes, features and advantages of the present invention more comprehensible, preferred embodiments are specifically cited below, together with the accompanying drawings, as follows:

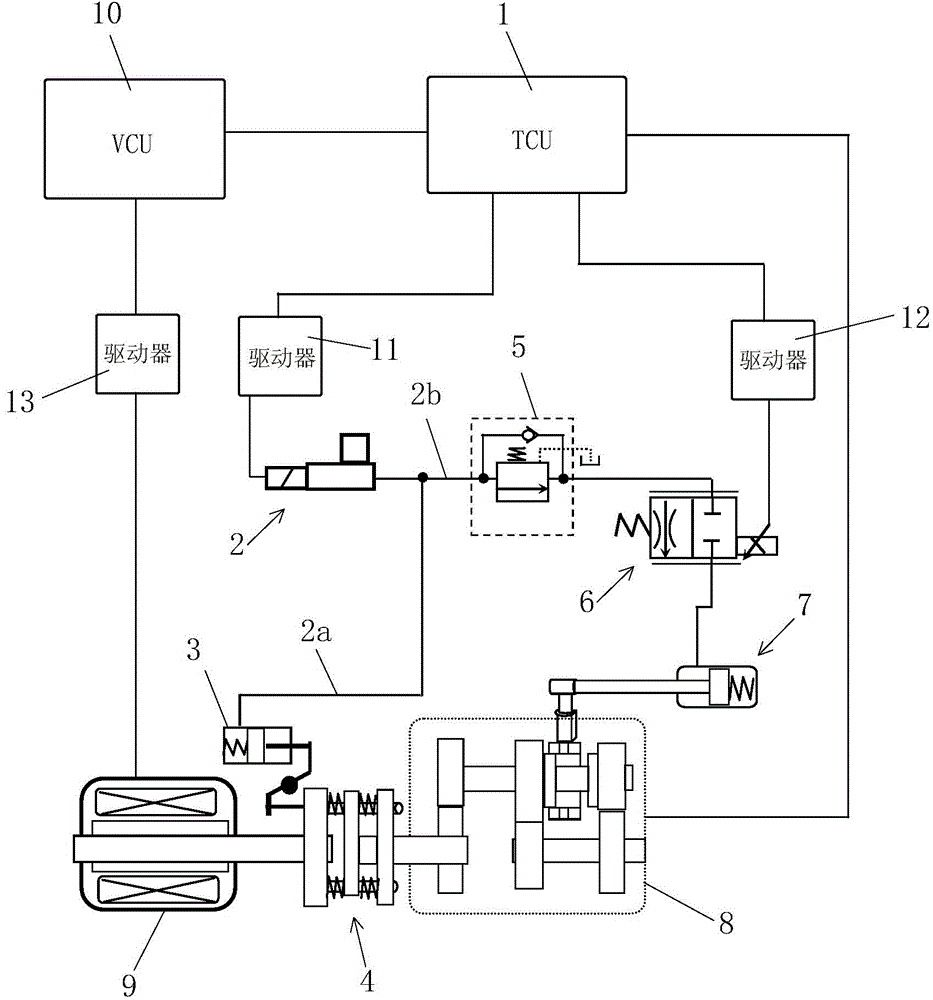

[0018] Please refer to figure 1 , which shows an automatic transmission shift system according to an embodiment of the present invention. This system is configured in a vehicle and at least includes: a transmission control unit (1), a hydraulic master cylinder (2), and a clutch actuator (3), a clutch (4), a sequence valve (5), a shift actuator shift valve (6), a shift actuator (7), and a gearbox (8).

[0019] The speed change control unit (1) can judge whether the vehicle shifts gears; in detail, it can judge whether to shift gears according to the driving parameters of the vehicle. The driving parameters include vehicle speed, accelerator opening, lever position, power source (9) speed or any combination of these. If it is decided to shift gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com