Gas leak detection non-uniform correction method and gas leak detection device

A gas leak detection and non-uniform correction technology, applied in the field of data identification, can solve problems such as poor effect and large temperature difference, and achieve the effects of improving detection accuracy, improving non-uniform correction effect, and improving gas non-uniform correction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

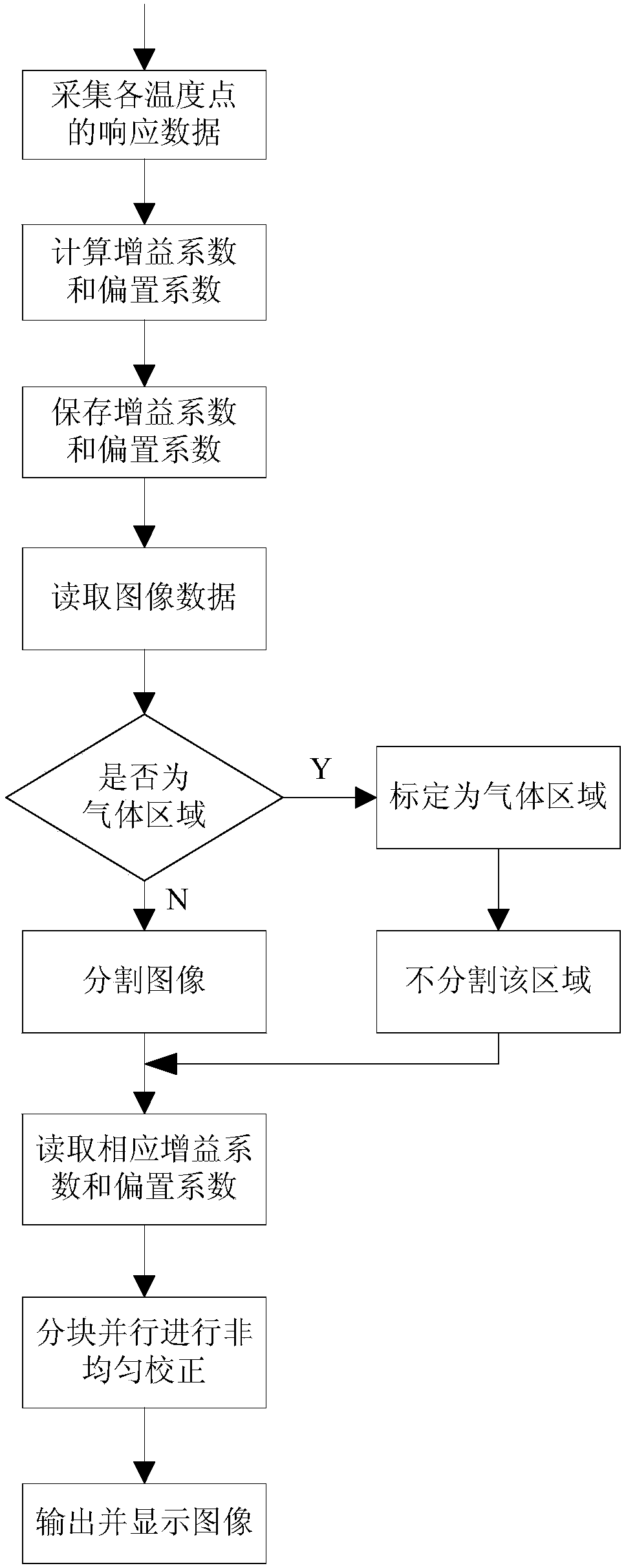

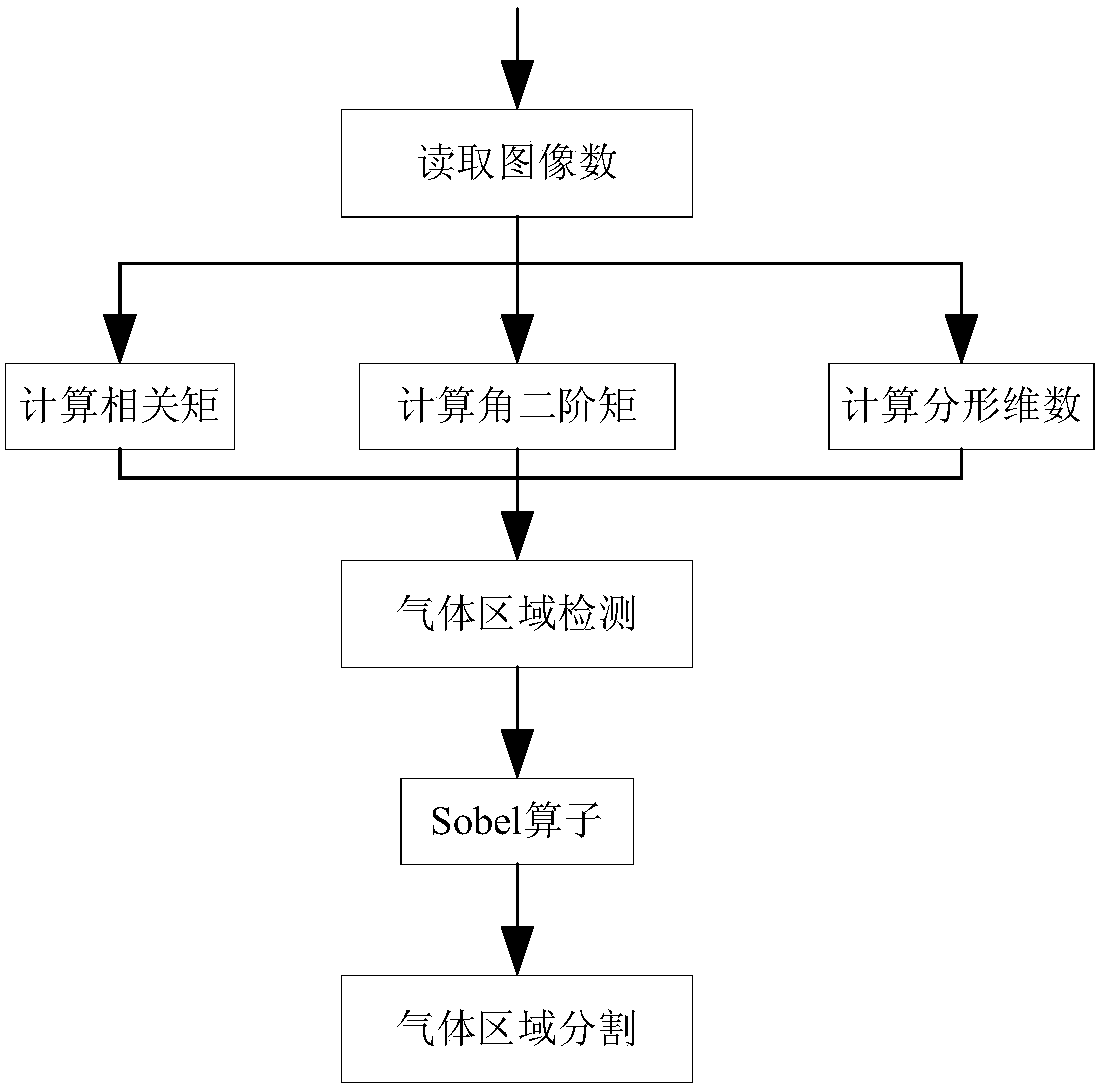

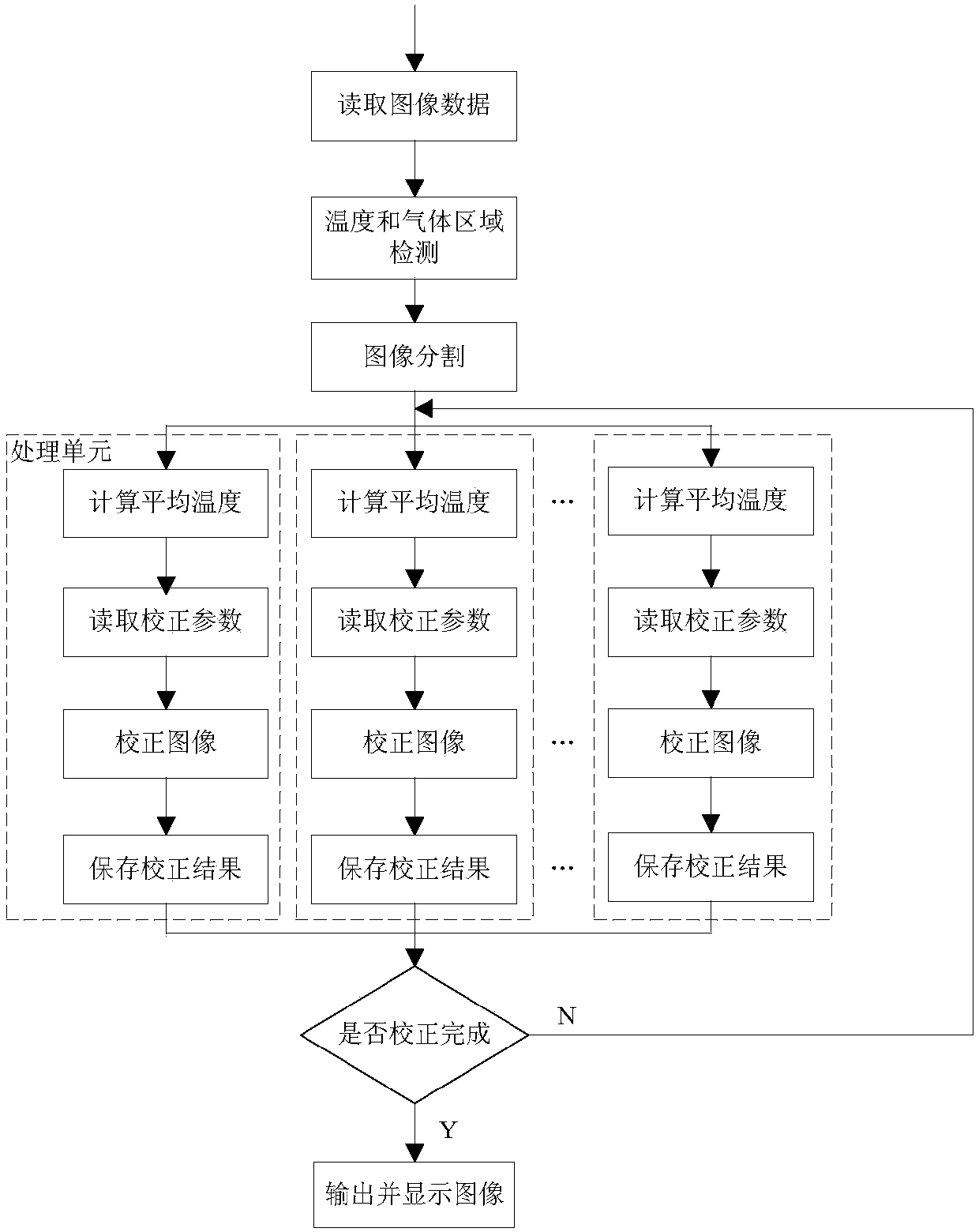

[0045] Such as figure 1 As shown, the non-uniform correction method for gas leakage detection in the present invention includes the following steps:

[0046] Step 1: Collect the response data of each photosensitive element of the infrared image sensor at each temperature value, and use the two-point correction method to calculate the gain coefficient G of each temperature segment using formula (1) and formula (2). ij and bias coefficient Q ij ,

[0047]

[0048]

[0049] where Xij (H) and X ij (L) are the responses of pixel (i, j) under high temperature and low temperature uniform radiation background respectively, V H and V L are the average output of all pixels in the focal plane array, respectively;

[0050] Step 2, for the gain coefficient G of each temperature section ij and bias coefficient Q ij store separately;

[0051] Step 3, the gas leakage detection device reads the gain coefficient G of each temperature section ij and bias coefficient Q ij ;

[00...

Embodiment 2

[0069] Such as Figure 4-6 This embodiment provides a gas leakage detection device on the basis of Embodiment 1, including a housing 1, a main control chip is arranged in the housing 1, and the main control chip is connected to an infrared imaging module, a display module and a power module 2, and the power module 2 supplying power to the remaining modules, the infrared imaging module includes an infrared lens 3 arranged in sequence, an infrared window 4 and an infrared image sensor, the infrared image sensor is arranged inside the casing 1, Figure 4-6 are not shown.

[0070] The display module includes an ordinary display module 5 and a strong light display module 6, the ordinary display module 5 is hinged to the housing 1, the back of the ordinary display module 5 is provided with control buttons 7, and the strong light display module 6 includes a screen cylinder and a display screen, The display screen is fixed in the screen barrel, and the common display module 5, the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com