Rolling bearing detection method based on LMD (Local Mean Decomposition) and gray correlation

A technology of local mean decomposition and gray correlation, applied in the field of mechanical engineering, can solve the problem that the data volume of the PF component cannot be used as a feature vector, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and technical solutions.

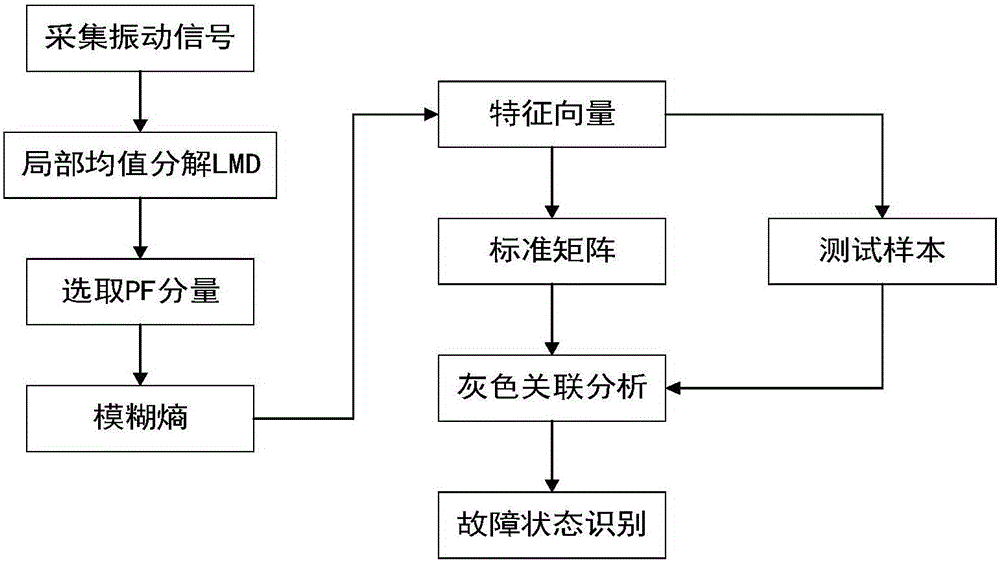

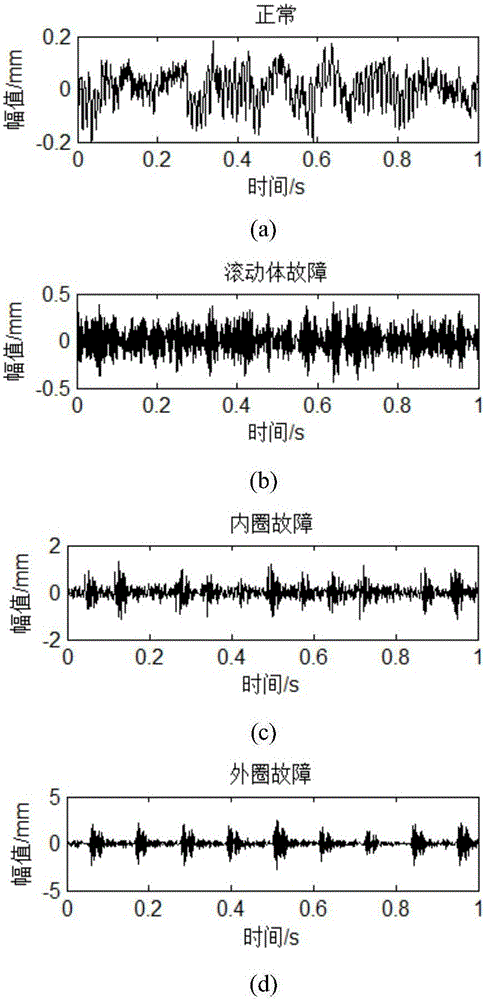

[0057] figure 1 This is the flow chart of the detection method. The power of the motor used in this test is 1.5KW, and the model of the bearing used in the test is SKF6205. The bearing speed is 1750r / min, the sampling frequency is 12KHz, and the fault diameter is 0.1778mm. The inner ring, outer ring and rolling body faults of the bearing are artificially processed by EDM. The operating state of the bearing is divided into normal, inner ring fault, rolling element fault and outer ring fault. The time domain waveform diagrams of the four bearing states are as follows figure 2 shown. The specific steps of the detection method are as follows:

[0058] The first step is to use the acceleration sensor to collect vibration acceleration signals of rolling bearings, including normal bearings without faults and bearing vibratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com