Loading and unloading simulation test system for double-track tunnel excavation face

A double-lane tunnel, simulation test technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve tunnel deformation damage, ground surface or ground structure damage, and damage to the surrounding soil balance state, etc. problem, achieve the effect of reducing friction, avoiding torsion and jamming, and facilitating adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

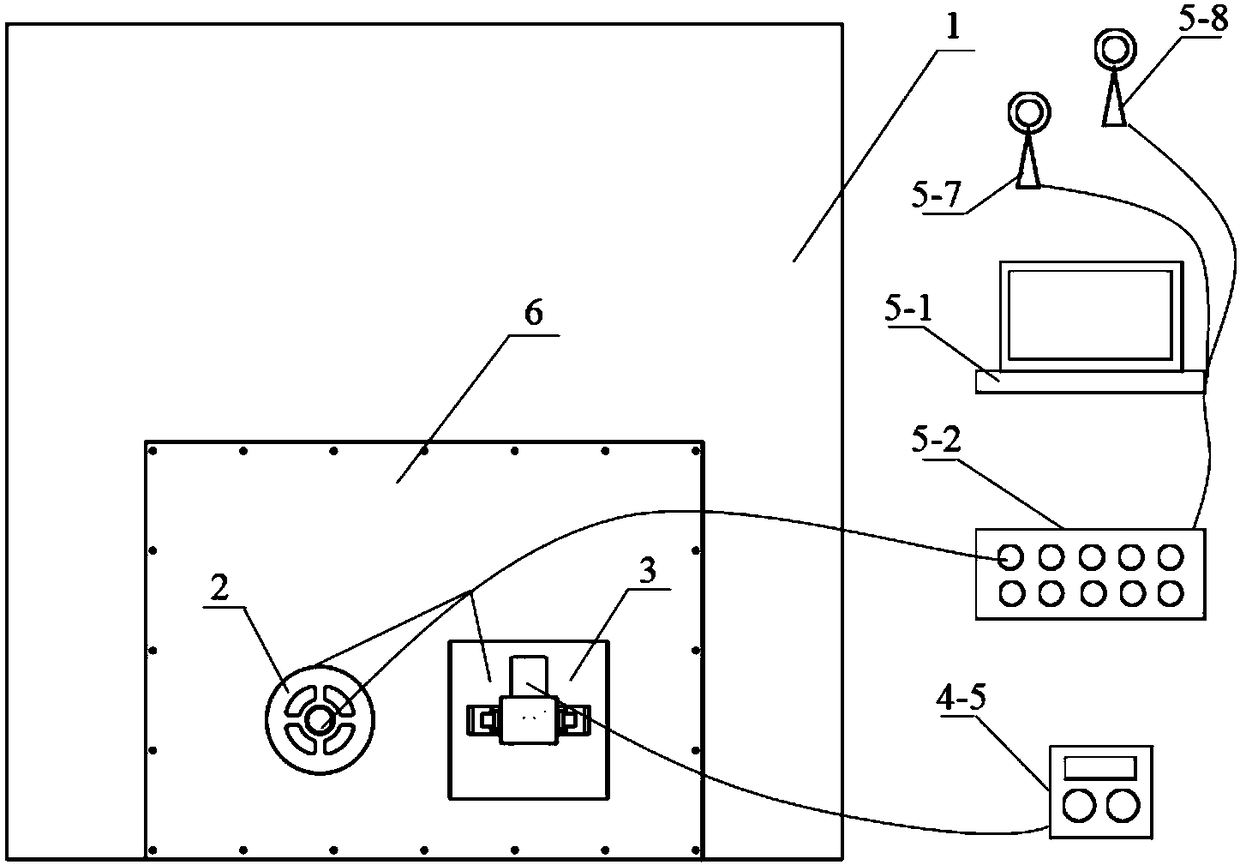

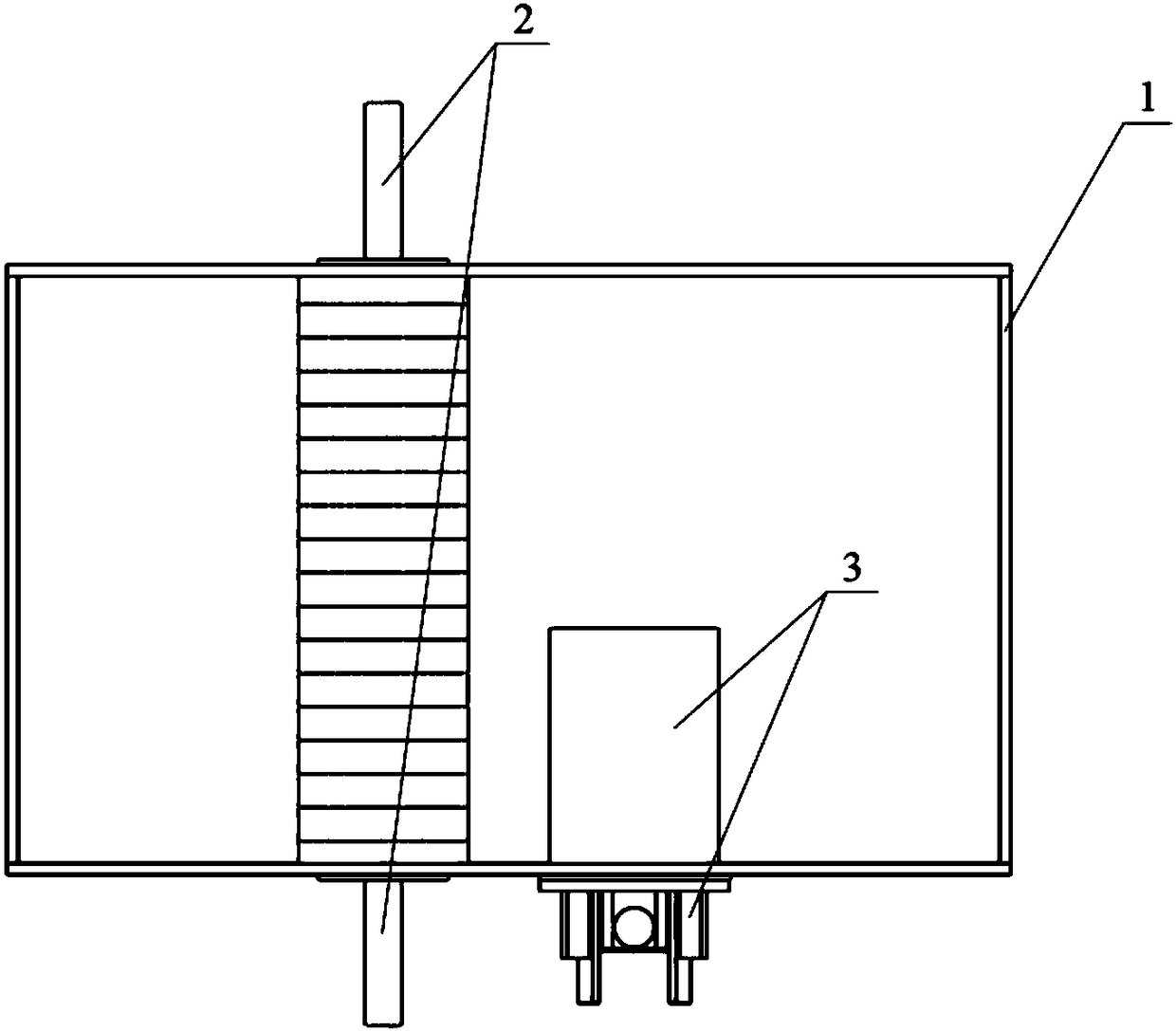

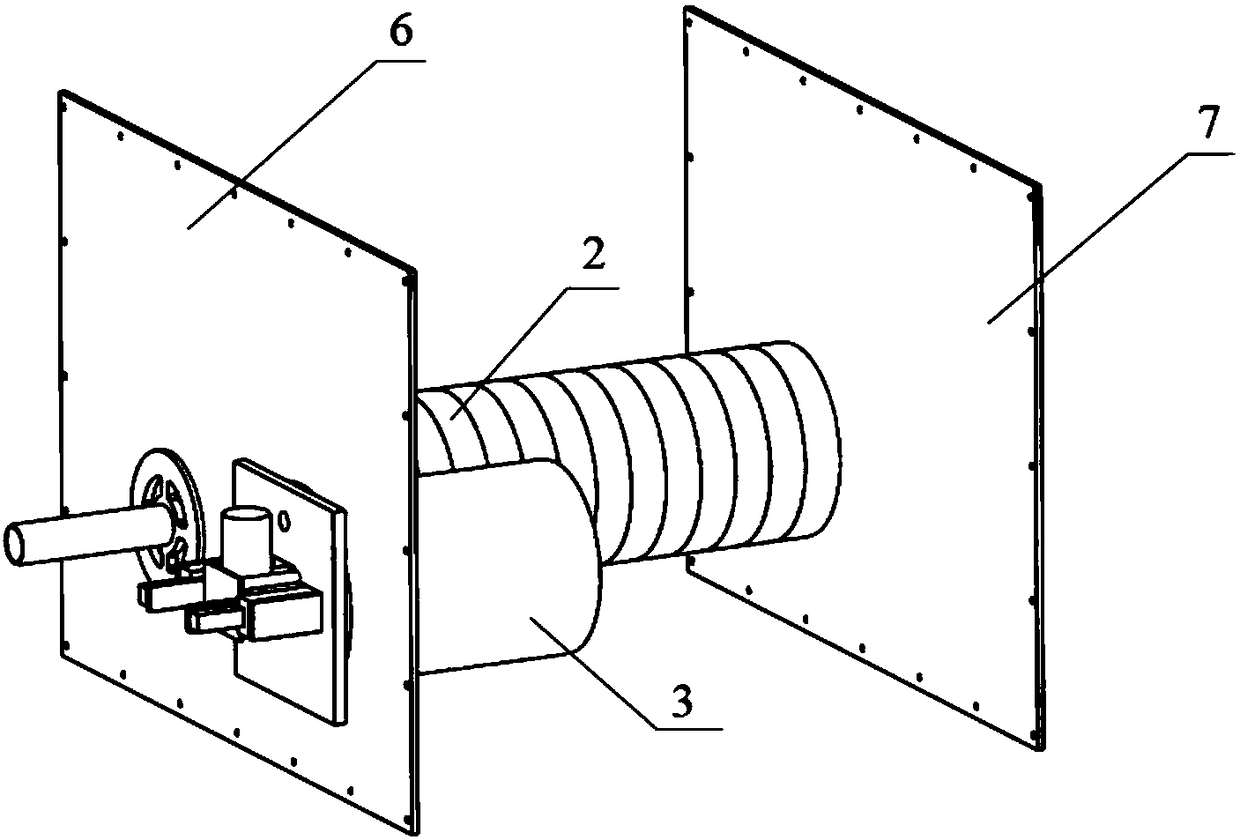

[0022] see Figure 1 to Figure 8 , a double-track tunnel excavation face loading and unloading simulation test system, including a test tank 1, an existing tunnel model 2, a new tunnel model 3, a loading system and a data acquisition system.

[0023] The existing tunnel model 2 is a model tunnel pipe buried in the test tank 1, the transverse stiffness and longitudinal stiffness of the model tunnel pipe form a corresponding relationship with the tunnel passage similarity ratio in the actual project, and the model tunnel pipe The two ends of each are vertically fixed on the front side wall and the rear side wall of the test tank 1 respectively, and the model tunnel pipe is formed by a plurality of model tunnel rings 2-1 connected in series, eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com