Reflective welding strip arranging device

A finishing device and reflective ribbon technology, which is applied in photovoltaic power generation, photovoltaic modules, photovoltaic system monitoring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below according to the drawings and embodiments.

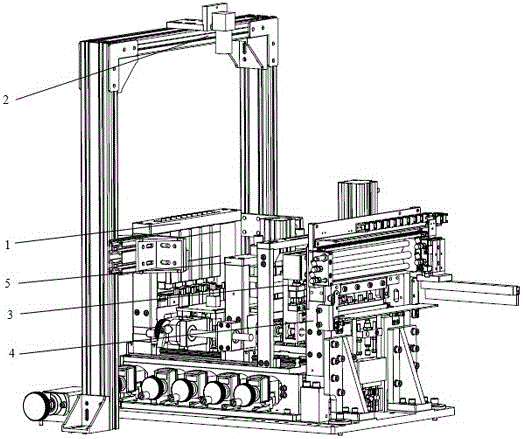

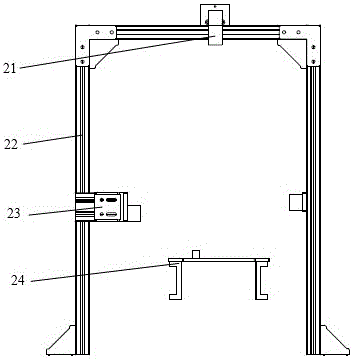

[0026] like figure 1 As shown, a reflective ribbon finishing device described in the embodiment of the present invention includes: a stretching mechanism 1; 2 is equipped with a feeding mechanism 3 in the rear path, and the feeding mechanism 3 includes multiple independent feeding parts corresponding to the number of welding ribbons, which are used for adjustment of a single welding ribbon; and the cutting is arranged in the rear path of the feeding mechanism 3 Mechanism 4, the cutting mechanism 4 has a cutting knife 41 for cutting off the welding ribbon. A movable bending mechanism 5 is also provided between the visual inspection mechanism 2 and the feeding mechanism 3 .

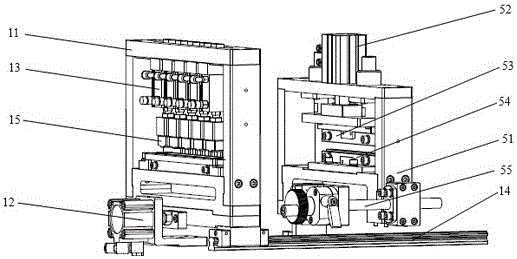

[0027] like figure 2 As shown, the stretching mechanism 1 includes a stretching clamping bracket 11, a stretching cylinder 12 and a clamping cylinder 13, the stretching clamping bracket 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com