Vibrational self-dedusting monitor

A monitor and self-dust removal technology, which is applied in the monitor field, can solve the problems of affecting the monitor’s shooting quality, reducing the monitor’s shooting effect, shortening the service life of the monitor, etc., achieving outstanding cleaning effect, low cost, and preventing excessive temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

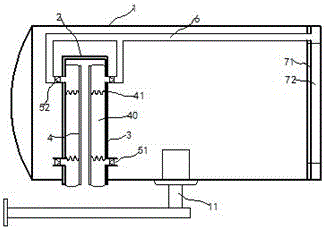

[0014] in figure 1 , figure 2 In the embodiment shown, the present vibrating self-dust removal monitor includes a lens, a housing 1 and a fixing bracket 11, and the fixing bracket 11 is installed at the lower part of the housing 1;

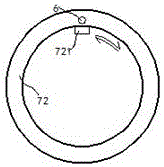

[0015] The housing 1 is provided with an echo groove 2, and on two opposite side plates 3 of the echo groove 2, a vibration plate 4 is respectively installed, and the distance between the two vibration plates 4 is 8-13mm; Each of the vibration plates 4 and the side plates 3 are connected by a vibration spring 41; a sealing film 42 is also wrapped between the vibration plate 4 and the side plate 3. The sealing film 42, the vibration plate 4 and the side plate 3 form two independent , A closed vibration chamber 40; each of the vibration chambers 40 are installed with a one-way intake valve 51 and a one-way exhaust valve 52, the one-way exhaust valve 52 is connected to the air duct 6, the air duct 6 along the housing 1 The inner wall extends to the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com