A chain ditch scarifier

A ripper and chain technology, which is applied in the fields of soil preparation machinery, agricultural machinery and implements, shovels, etc., can solve the problems of no automatic trencher and large labor input, and achieve high work efficiency, reduced investment, and depth control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

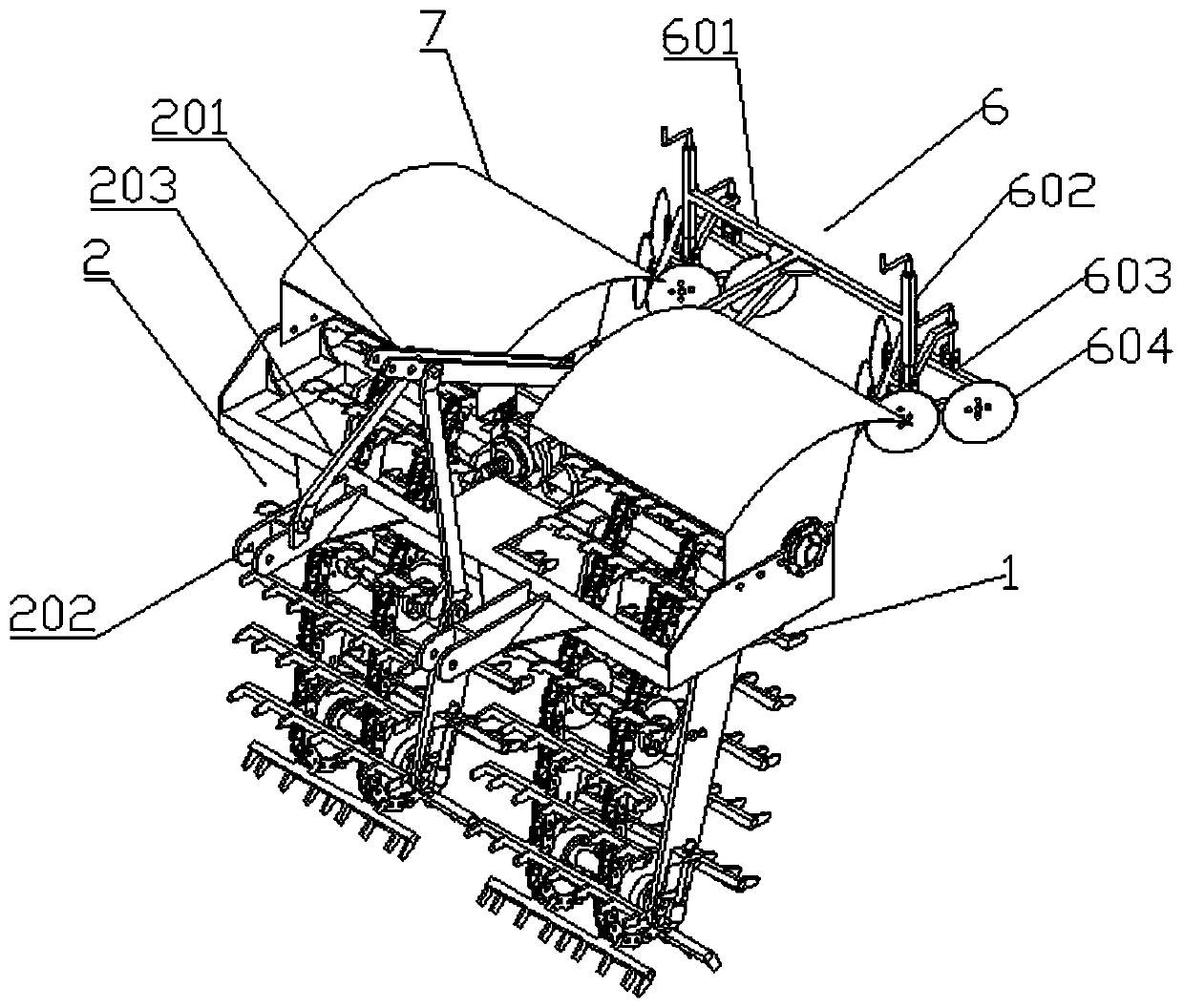

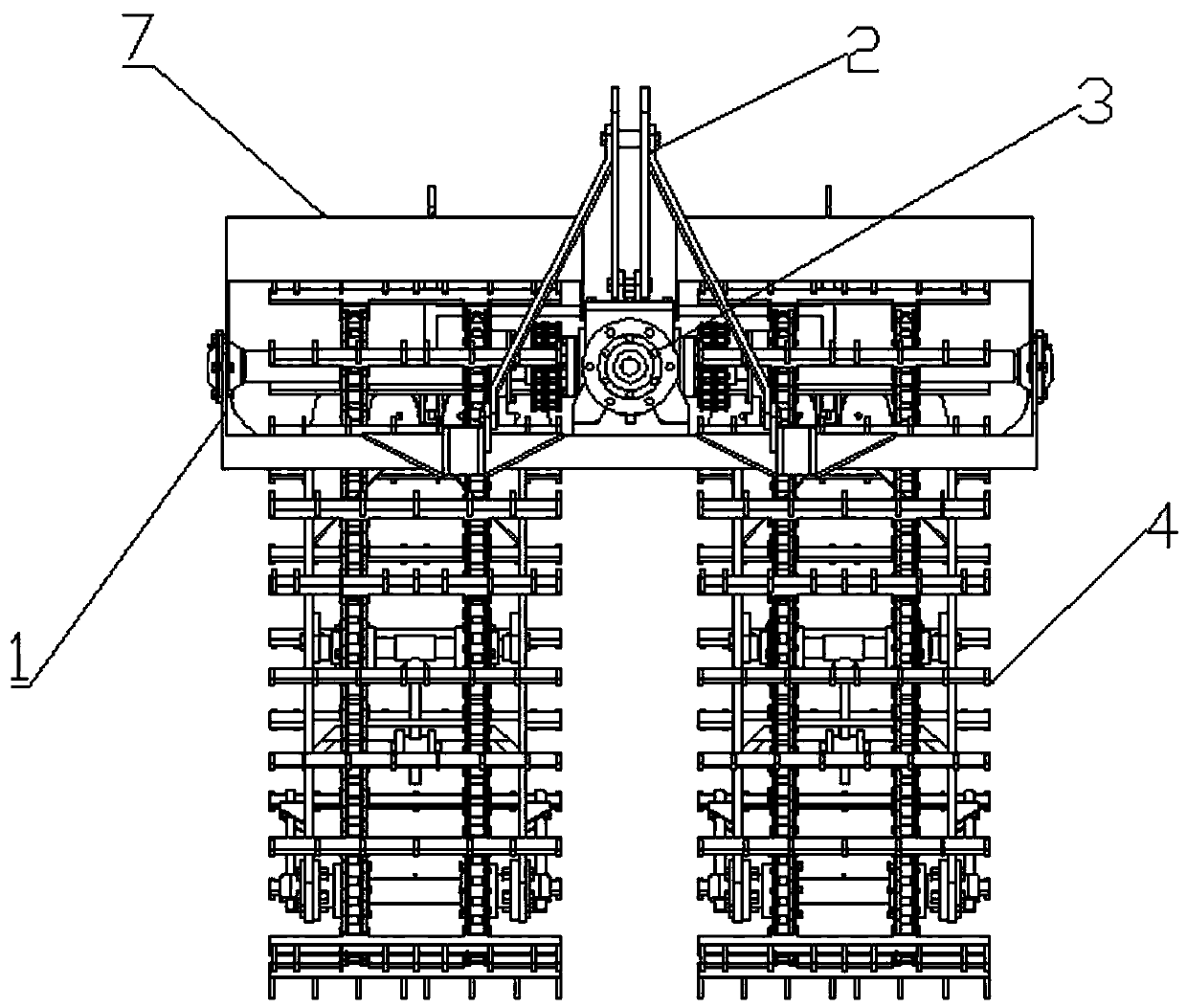

[0031] Such as Figure 1-5 As shown, a chain type ditching scarifier includes: a frame 1, the frame 1 is movably connected with a locomotive through a connecting frame 2, and the chain type ditching scarifier is moved forward by the traction of the locomotive;

[0032] Fixed on the frame 1, with the reduction box 3 of the engine power transmission of the locomotive, the torque is increased, and the output power of the ditching and loosening device is improved;

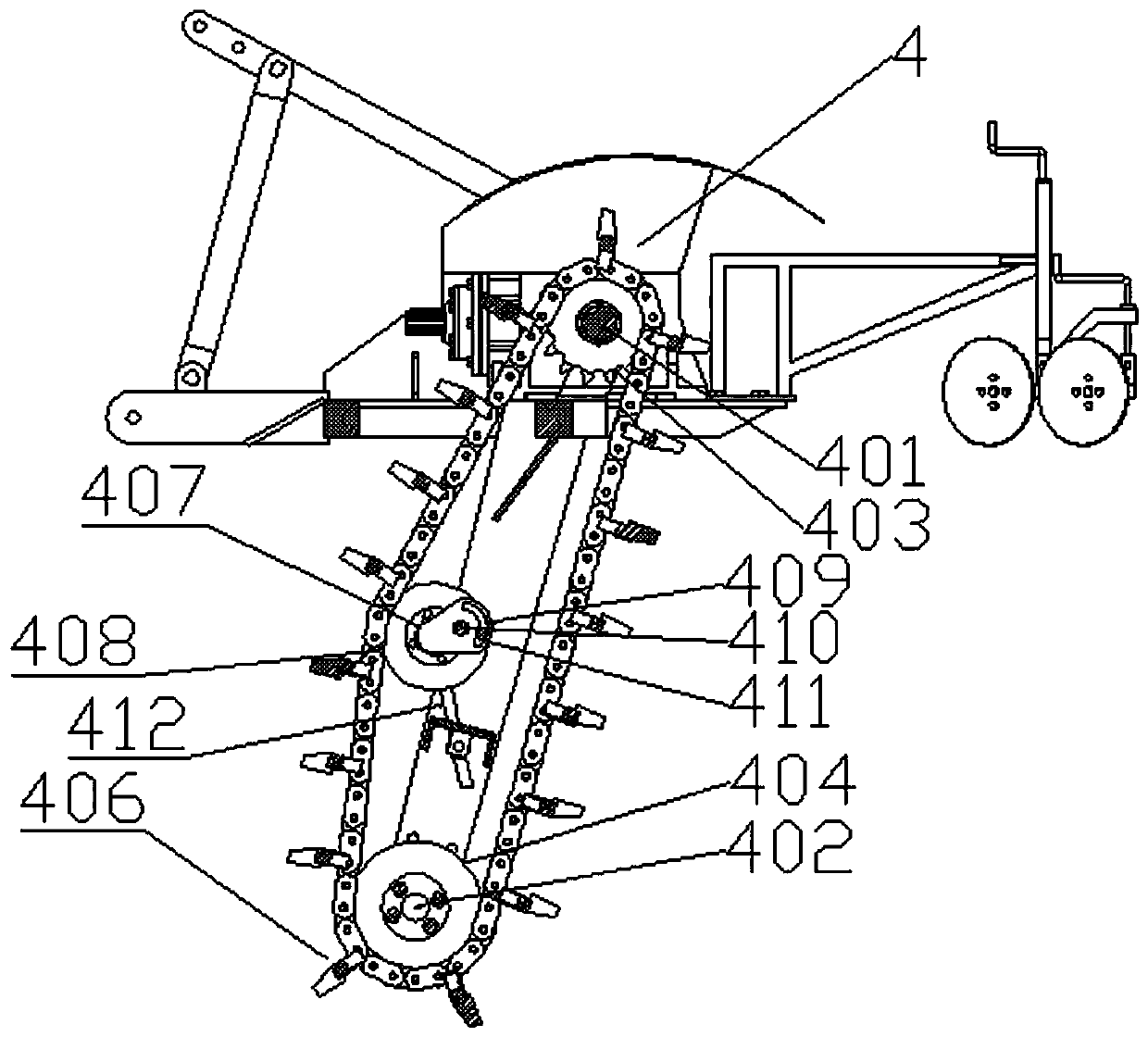

[0033] The ditching and loosening device 4 is arranged on the frame 1 and connected with the power output shaft of the reduction box 3; the ditching and loosening device 4 includes a The driving shaft 401 and the driven shaft 402; the driving shaft 401 is located at the upper end of the frame 1, and the driving shaft 401 is provided with two sprockets 403 at intervals; the driven shaft 402 is located at the lower end of the frame 1 , and the driven shaft 402 is provided with two guide wheels 404 at intervals; the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com