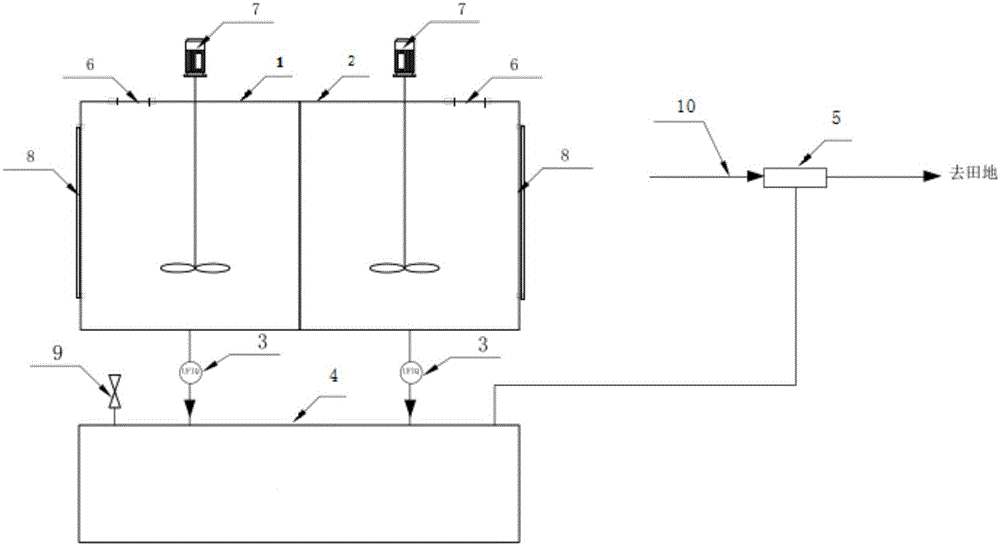

Chlorine dioxide soil disinfectant and special equipment therefor

A technology of soil disinfectant and chlorine dioxide, which is applied in the direction of disinfectant, botany equipment and method, application, etc., can solve the problems of chlorine dioxide gas spillage loss, inaccurate dose dosage, environmental and personnel pollution, etc. To achieve the effect of benefiting plant growth, accurate dosing and dosing of chemicals, and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Component A: Weigh 300g of sodium chlorite and 200g of calcium sulfate, mix the two evenly in a non-metallic container in a ventilated and dry environment, put them into an aluminum foil packaging bag, and seal it. Component B: Weigh 150g of oxalic acid and 350g of sodium bisulfate, mix the two evenly in a non-metallic container in a ventilated and dry environment, put them into aluminum foil packaging bags, and seal them.

Embodiment 2

[0030] Component A: Weigh 350g of sodium chlorite and 150g of calcium sulfate, mix the two evenly in a non-metallic container in a ventilated and dry environment, put them into an aluminum foil packaging bag, and seal it. Component B: Weigh 200g of oxalic acid and 300g of sodium bisulfate, mix the two evenly in a non-metallic container in a ventilated and dry environment, put them into aluminum foil packaging bags, and seal them.

Embodiment 3

[0032] Component A: Weigh 400g of sodium chlorite and 100g of calcium sulfate, mix them evenly in a non-metallic container in a ventilated and dry environment, put them into aluminum foil packaging bags, and seal them. Component B: Weigh 250g of oxalic acid and 250g of sodium bisulfate, mix the two evenly in a non-metallic container in a ventilated and dry environment, put them into aluminum foil packaging bags, and seal them.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com