Horizontal quick clamp

A horizontal and fast technology, applied in the direction of clamping, manufacturing tools, workpiece clamping devices, etc., can solve the problems of increasing production costs, time-consuming and labor-intensive, and can not improve efficiency, etc., to achieve convenient installation, wide application range, and save manual operation the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further illustrate the technical means adopted by the present invention and the technical effects achieved, the following describes in detail in conjunction with the accompanying drawings and preferred embodiments.

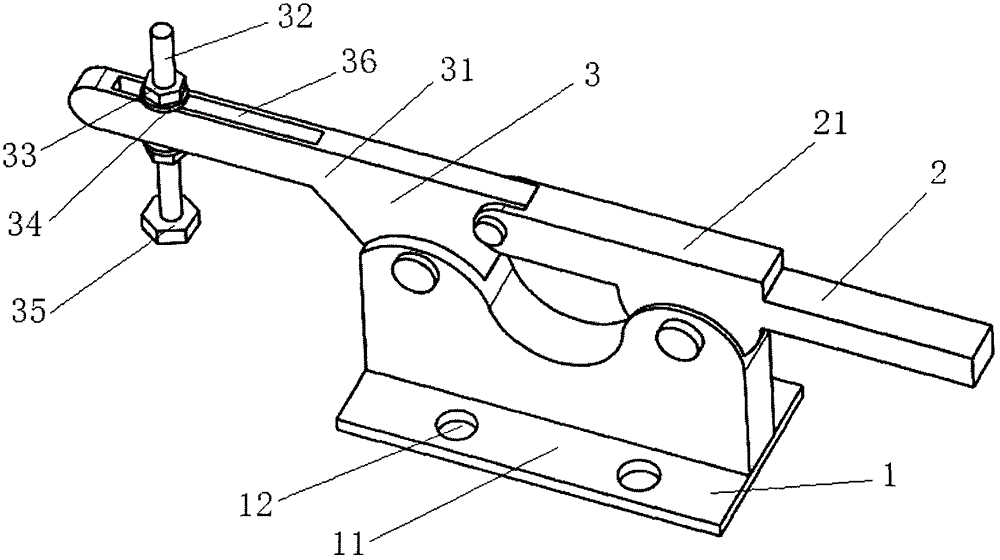

[0015] refer to figure 1 , in this embodiment, the horizontal quick clamp of the present invention includes a positioning part 1 , an operating part 2 and a clamping part 3 . The positioning part includes a positioning seat 11, and a positioning hole 12 is provided on the bottom plate of the positioning seat 11 extending outward. The operating part 2 includes an operating handle 21, and the part near the front end of the operating handle 21 is connected to the positioning part 1 through a bolt movable shaft, so that the operating handle 21 rotates around the bolt. The clamping part 3 is arranged on the other end of the positioning part 1 opposite to the operating part 2. The clamping part 3 includes a clamping rod 31, a clamping bolt 32, a fast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com