High-efficiency numerically-controlled machine tool

A CNC machine tool, high-efficiency technology, applied in the direction of metal processing mechanical parts, clamping, support, etc., can solve the problems of low efficiency, complex structure, high cost, and achieve the effect of reducing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the embodiments of the drawings.

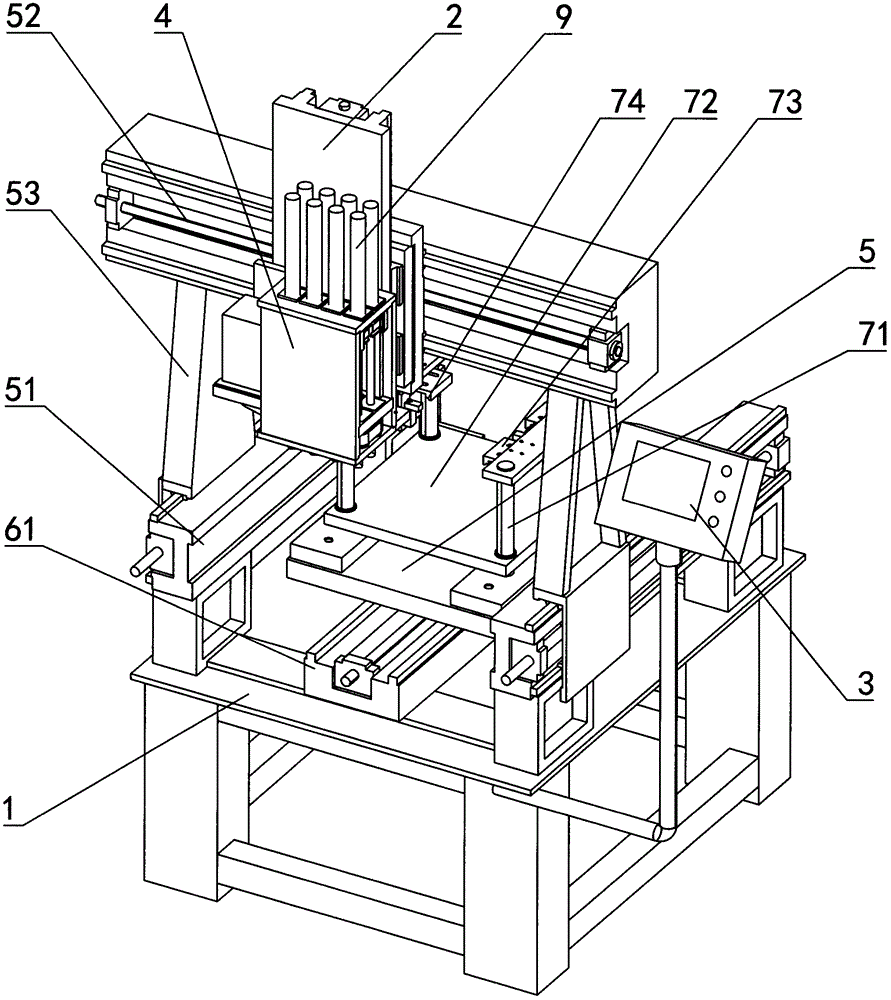

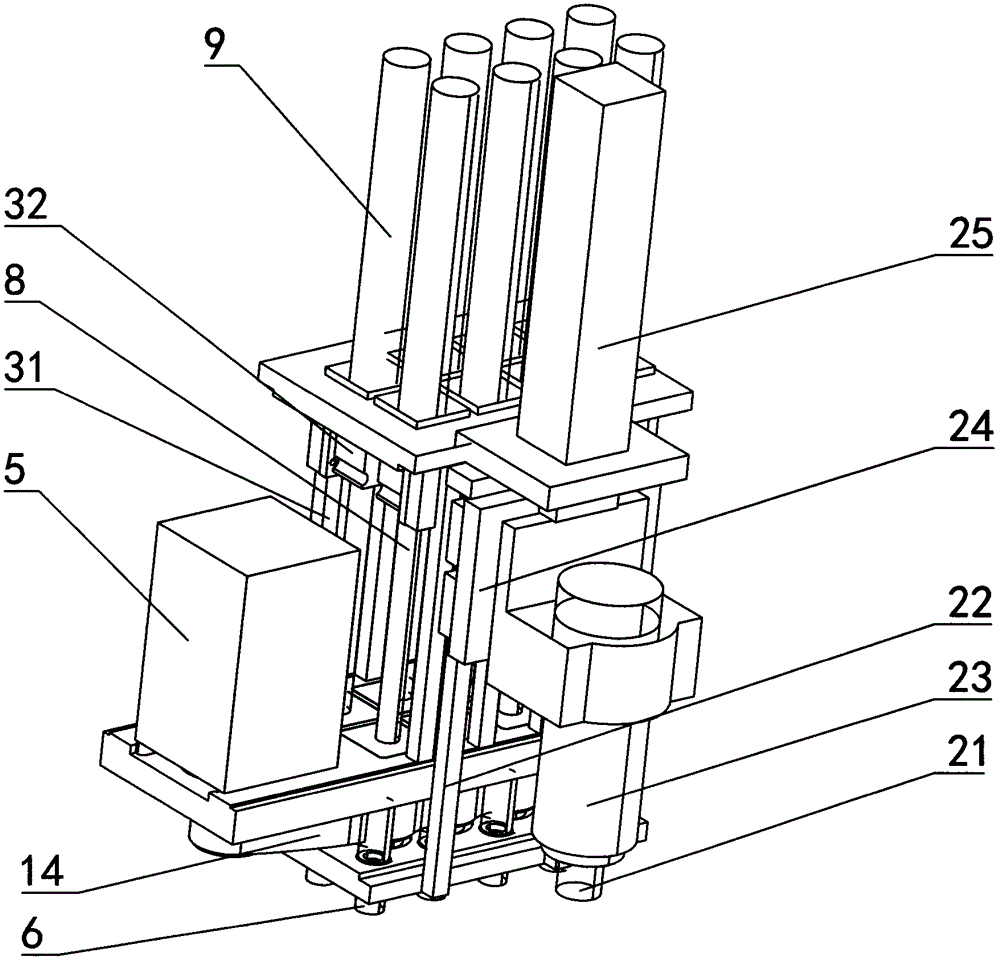

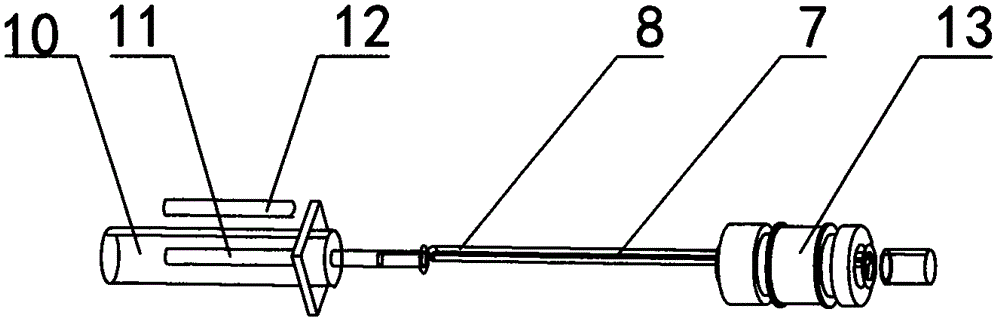

[0024] Such as Figure 1 to Figure 3 Shown: a high-efficiency numerical control machine tool, including a frame 1, a driving device and a numerical control device 3 located on one side of the frame 1. The driving device moves under the control of the numerical control device 3, and a fixed fixture 5 is arranged on the frame 1. A tool holder 4 is arranged above the frame 1, and a servo motor 5 and a plurality of different types of regularly arranged tools 6 are arranged on the tool holder 4. The tools 6 are connected to each other through a connecting rod 8 provided with a long and narrow groove 7. The first cylinder 9 is connected, and the connecting rod 8 is sleeved with a metal sleeve 10 that is shorter than the connecting rod 8. The metal sleeve 10 is provided with a notch 11 corresponding to the groove 7, and a retaining member 12 is installed in the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com