Improved corrugated board production line and production process thereof

A technology for corrugated cardboard and corrugated paper, which is applied in the field of improved corrugated cardboard assembly line and its production process, can solve the problems of poor control of roasted ribs, affecting product quality, affecting product quality, etc., so as to save the cost of varnish and have a compact structure. , Save the effect of pre-printing and post-printing links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

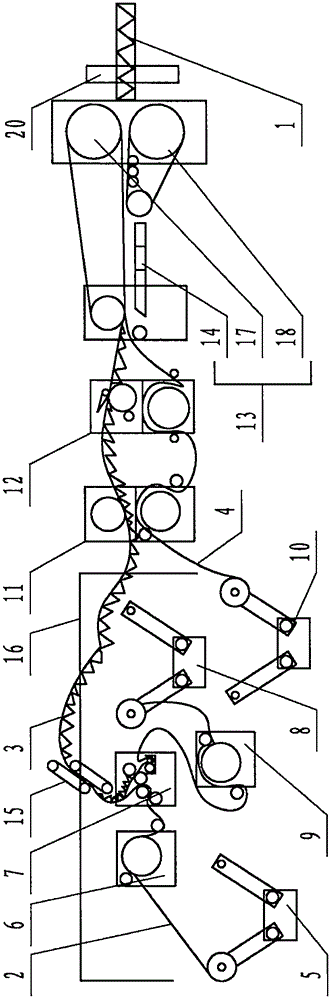

[0032] Existing corrugated paper lines such as figure 1 As shown, it is necessary to increase the whole preheating cylinder before the paster 12 for secondary preheating, and the corrugated surface paper 4 is in contact with the hot plate 14 . Corrugated board 1 is generally formed by bonding three layers of corrugated lining paper 2, corrugated paper 3 and corrugated surface paper 4. Corrugated paper can be used for printing patterns outside.

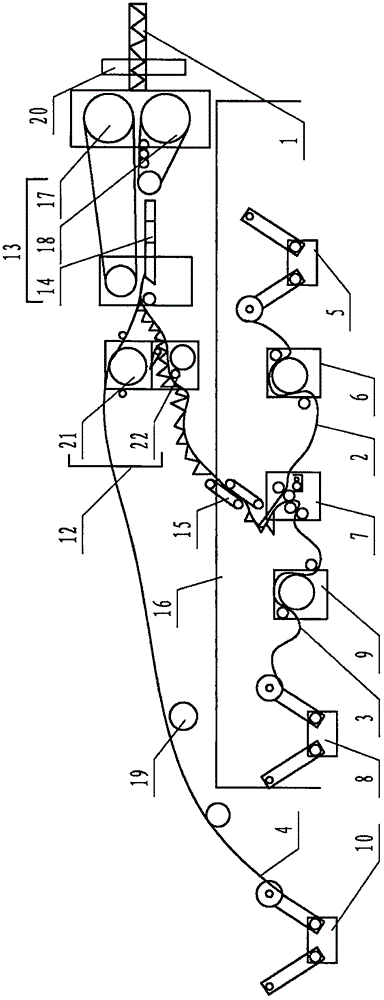

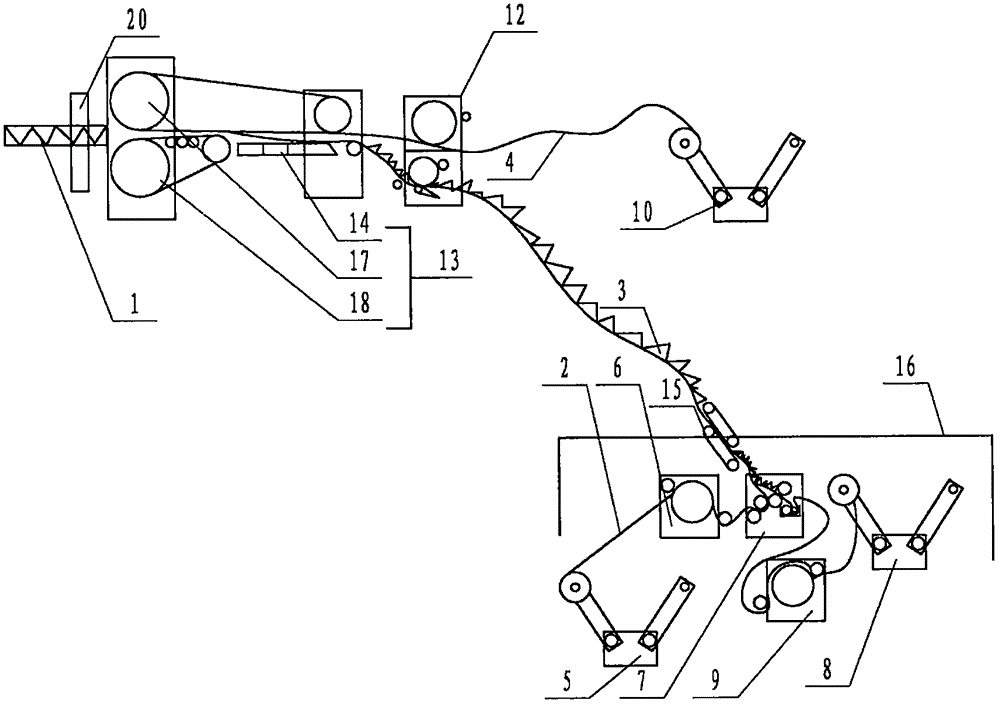

[0033] Such as Figure 2-4 As shown, the present invention includes a lining base paper frame 5 for placing the corrugated lining paper 2 of the corrugated board 1, a lining paper preheating cylinder 6 for heating the corrugated lining paper 2, and an inner paper preheating cylinder 6 for placing the corrugated paper 3 of the corrugated board 1. Corrugated paper base frame 8, corrugated paper preheating cylinder 9 for heating corrugated paper 3, corrugating machine 7 for making corrugated paper 3 and bonding corrugated lining paper 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com