Tensioning device with tension and gravity capable of being adjusted synchronously and on lower portion of elevator

A technology of tensioning device and hoist, which is applied in the direction of conveyor, transportation and packaging, etc. It can solve the problems of increasing load, occupying a large space, and failing to adjust the rotating mechanism, so as to prevent off-chain or off-belt, reliable operation of equipment, The effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

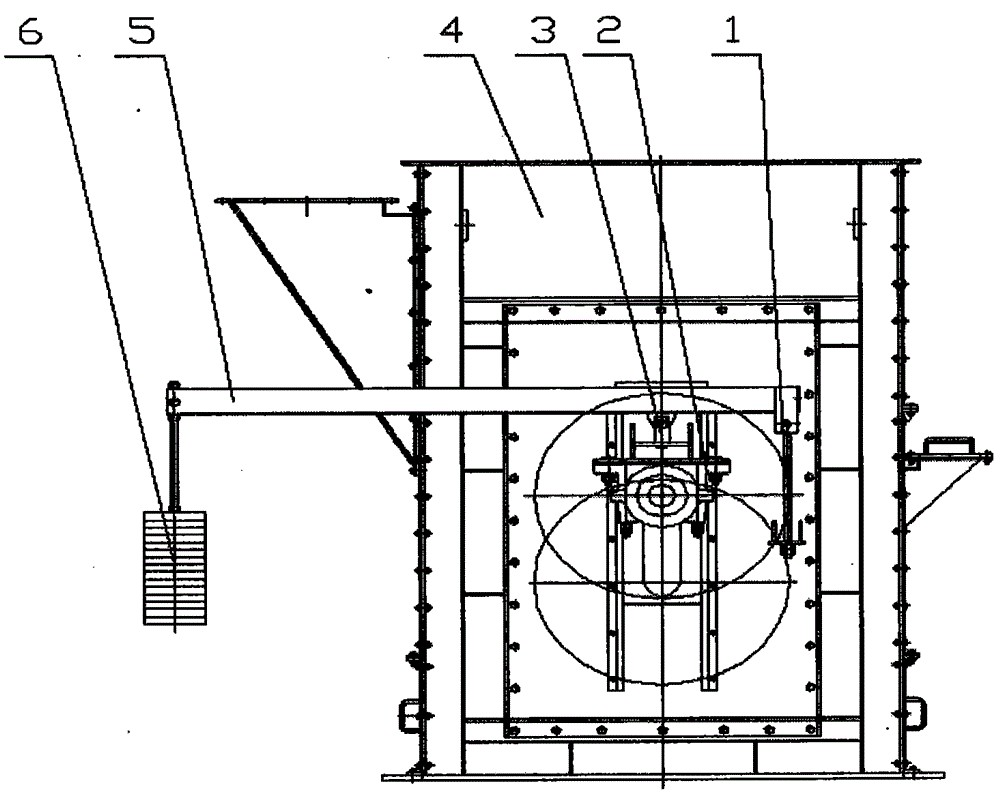

[0014] Such as figure 1 As shown, the synchronously adjustable tension gravity tensioning device at the lower part of the hoist includes a weight mechanism 6 and a lever 5. The lever adjustment mechanism 1 is installed on the lower casing 4 of the hoist and connected to one end of the lever 5, and the other end of the lever 5 is connected to the weight Mechanism 6, the middle part of the lever 5 is connected to the lever rotating shaft mechanism 3 through the sliding support plate 2, and the lever rotating shaft mechanism 3 is connected to the redirection sprocket assembly or the pulley assembly at the lower part of the hoist.

[0015] The lever adjustment mechanism 1 is a nut screw structure, including an adjustment screw, an adjustment nut, a lock nut, a screw nut fixing support, a screw connecting shaft, a shaft positioning pin or a collar.

[0016] The sliding supporting plate 2 on the bearing block comprises a lever rotating shaft supporting seat and a sliding plate.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com