A kind of feeding mechanism and feeding method of threading machine

A feeding mechanism and threading machine technology, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of affecting production progress, low work efficiency, poor practicability, etc., and achieve high production efficiency, simple structure, and practicality strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

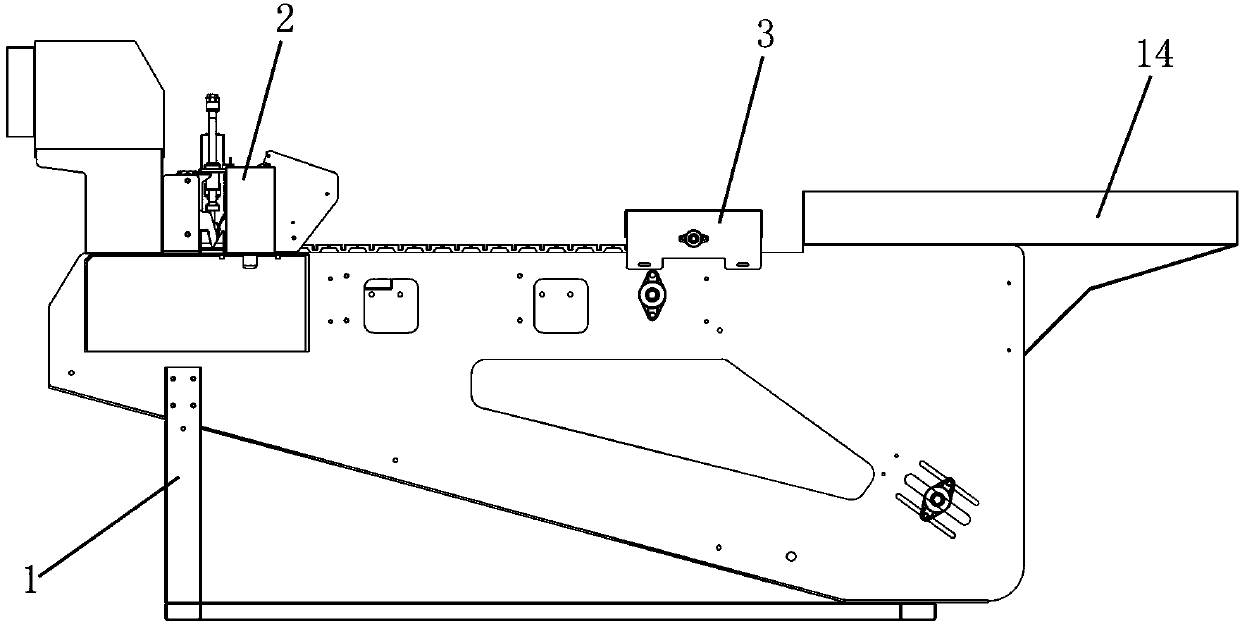

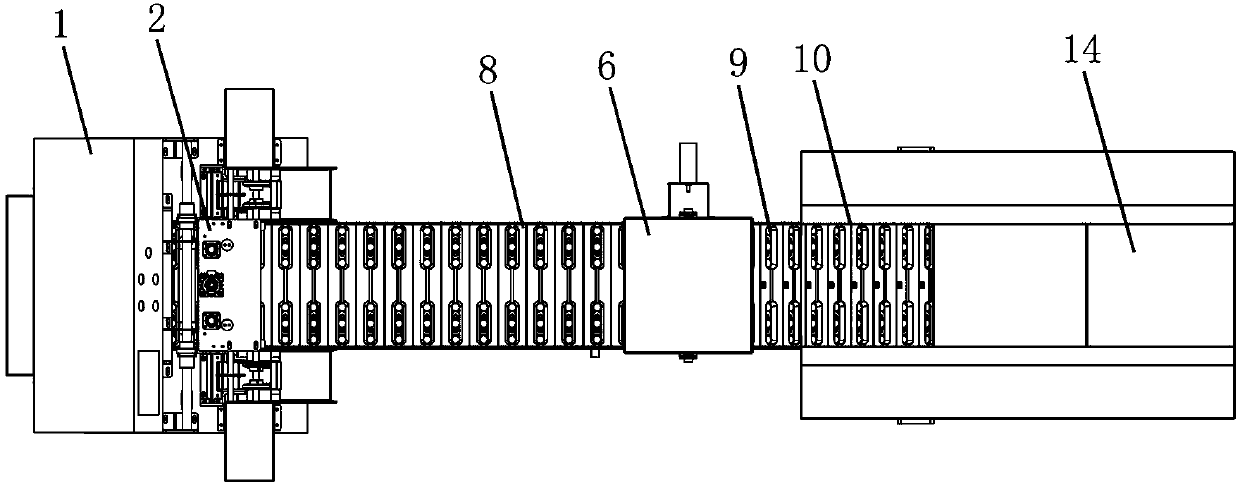

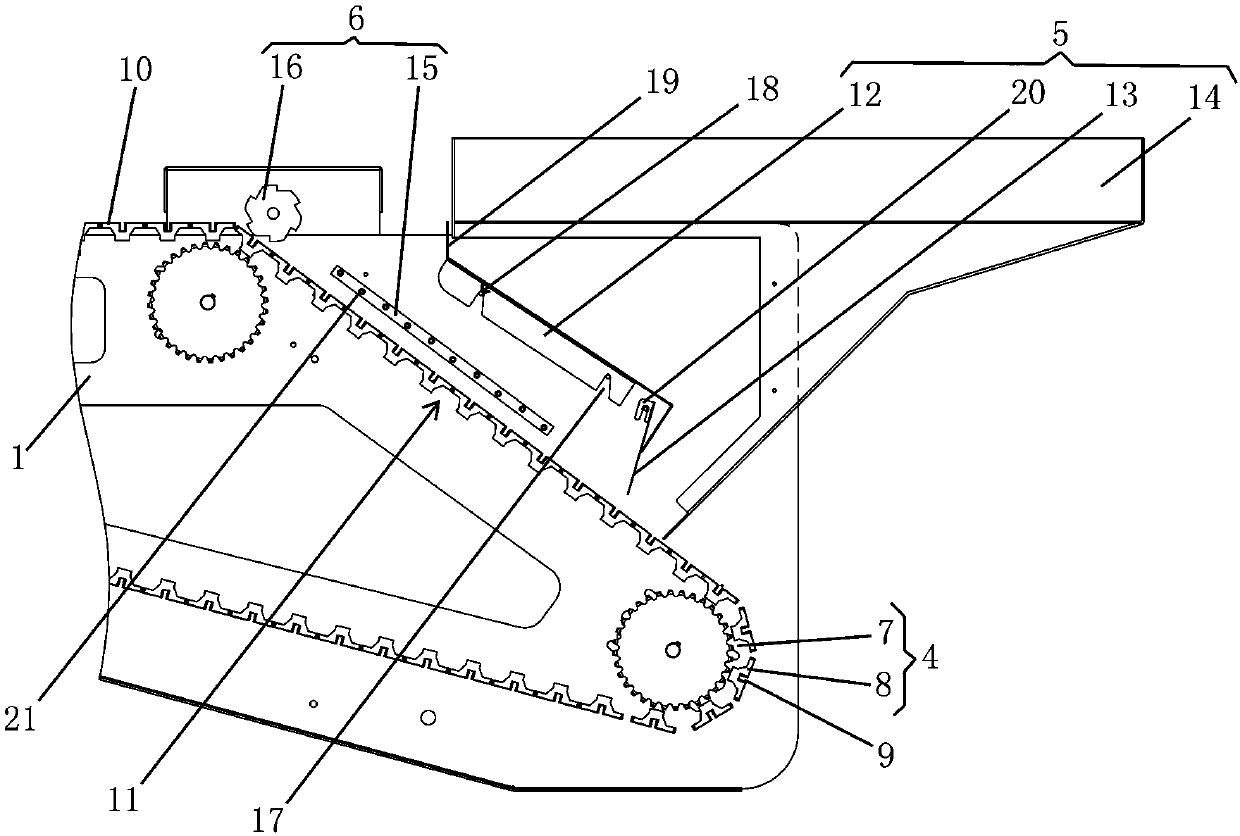

[0024] Such as Figure 1-4 As shown, a feeding mechanism of a threading machine includes a frame 1, a stringing device 2 and a feeding device 3 respectively arranged on the frame 1, and the feeding device 3 includes a feeding mechanism 4 and a storage mechanism 5 And distribution mechanism 6;

[0025] The feeding mechanism 4 is composed of a conveyor belt 7 and a threading fixture 8 arranged on the conveyor belt 7. The threading fixture 8 is provided with a plurality of receiving grooves 9, and the threading fixture 8 is covered in an array. A feeding belt 10 is formed on the outside of the conveyor belt 7, and slides along with the moving direction of the conveyor belt 7, and the feeding belt 10 is provided with an inclined portion 11 having a certain inclination angle;

[0026] The material storage mechanism 5 includes a material retaining plate 12, a turning plate 13 and a hopper 14, and the material retaining plate 12 and the hopper 14 are detachably installed on the fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com