Method and device for producing hydrocarbons from methanol with step-by-step adjustment of injection cycle staged reaction

A methanol-to-hydrocarbon and reaction device technology, which is applied in the preparation of liquid hydrocarbon mixtures, the petroleum industry, biological raw materials, etc., can solve the problems of large investment in power equipment, large power consumption, and many types of by-products, and achieve the effect of reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

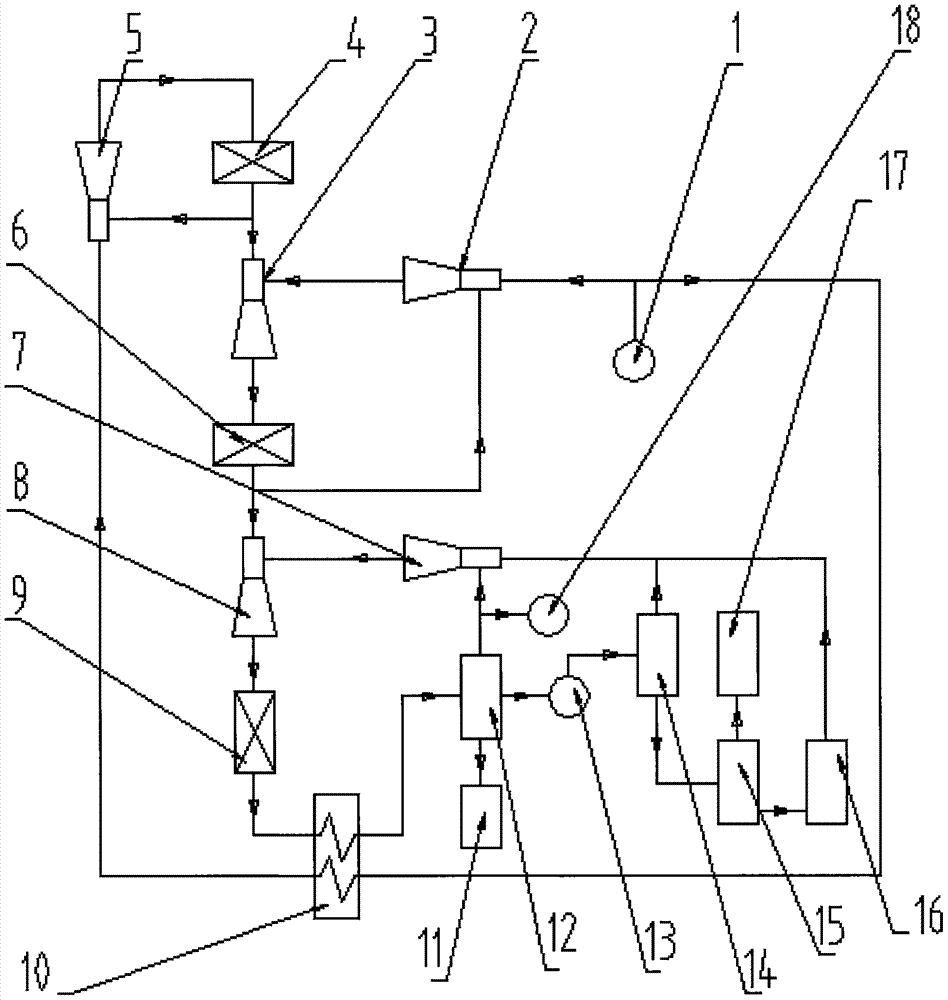

[0062] Embodiment 1: methanol gasoline

[0063] Gasoline is a mixture of hydrocarbons with carbon numbers ranging from C4 to C12, and it is allowed to contain an appropriate amount of alcohol ether ester components. Isoparaffin is a high-quality component, with high octane number of aromatics and relatively high octane number of olefins, but the content of aromatics in olefins is limited. Low-carbon hydrocarbons have high octane numbers but high vapor pressures, so they should be separated and converted. Long-chain alkanes have low octane numbers and should be separated and transformed. High-boiling aromatic components affect vehicle performance and should also be separated and transformed.

[0064] The advantage of the present invention is that through the step-by-step reaction and step-by-step adjustment method, the gasoline produced in the methanol-to-gasoline process contains more high-quality gasoline with high-quality components, and the by-product-free yield is reduce...

Embodiment 2

[0066] Embodiment 2: methanol diesel component

[0067] Diesel oil is a mixture of various hydrocarbons with carbon numbers ranging from C10 to C22, and it is allowed to contain an appropriate amount of alcohol ether ester components. Long-chain alkanes are high-quality components with high cetane number and high freezing point. Monocyclic long side chain aromatics and naphthenes have moderate cetane number and freezing point. Compared with the methanol-to-gasoline process, the post-reactor uses stacked catalysts.

[0068] The raw material methanol is boosted to 2.5-2.6 MPa by the methanol raw material pump 1 and divided into two paths, one path is used as the working fluid of the methanol injector 2; -200°C, the pressure is 2.3-2.4 MPa and then enters the pre-injector 5 as the working fluid to eject the part of the 300-400°C product at the outlet of the pre-reactor 4, then mix and heat up to 230-260°C, the pressure is 2.2-2.3 After MPa, it enters the pre-reactor 4 to react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com