Method for ordinary pressure continuous extraction of grease from schizochytrium limacinum cake and equipment thereof

A Schizochytrium and extraction technology, applied in the direction of fat oil/fat production, fat production, etc., can solve the problem of large microbial oil production capacity, and achieve the effect of small solvent amount and solvent loss saving

Active Publication Date: 2016-08-24

青岛海智源生命科技有限公司 +1

View PDF4 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the design principle of the existing atmospheric pressure extraction device makes the production capacity too large for microbial oil. The mainstream high-cost continuous vegetable oil extraction device is rarely less than 1000TPD (tons/

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

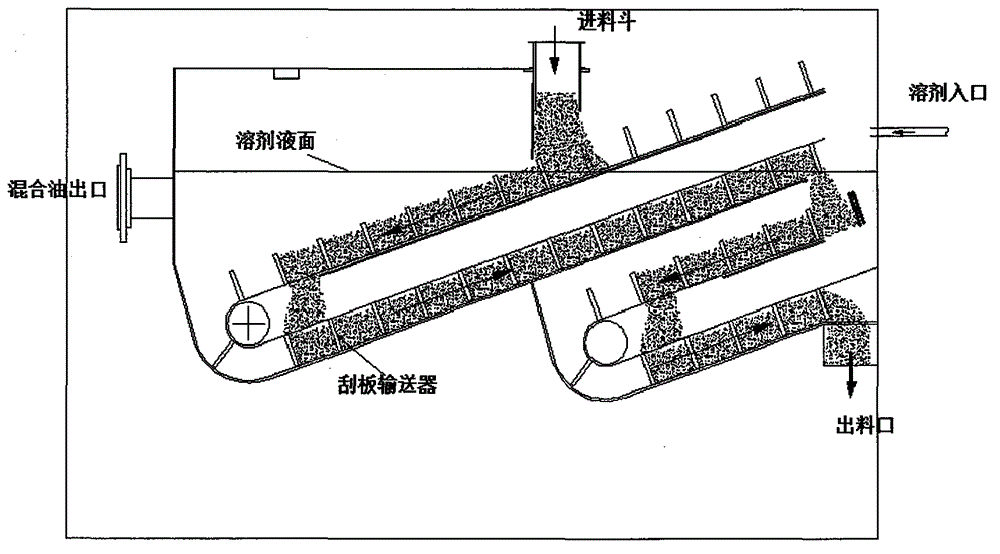

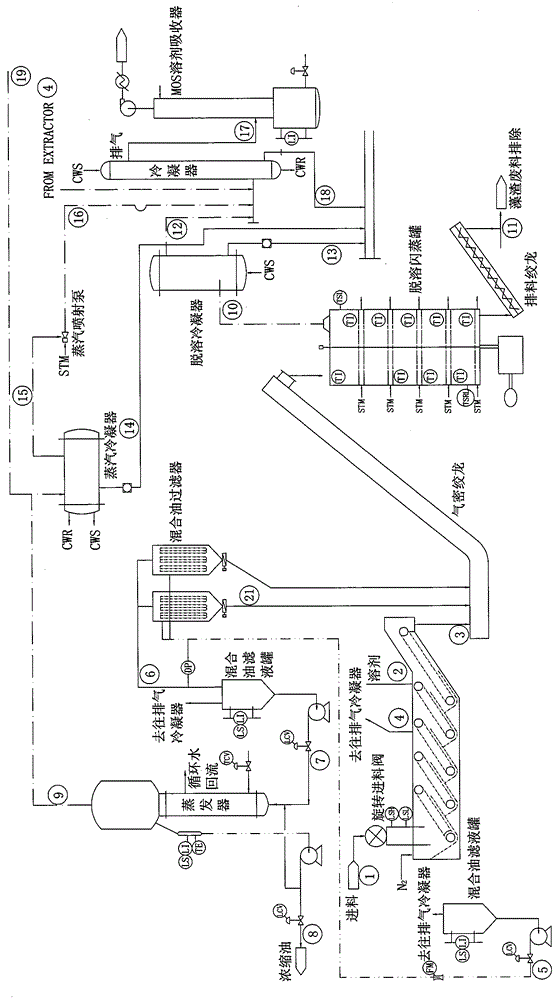

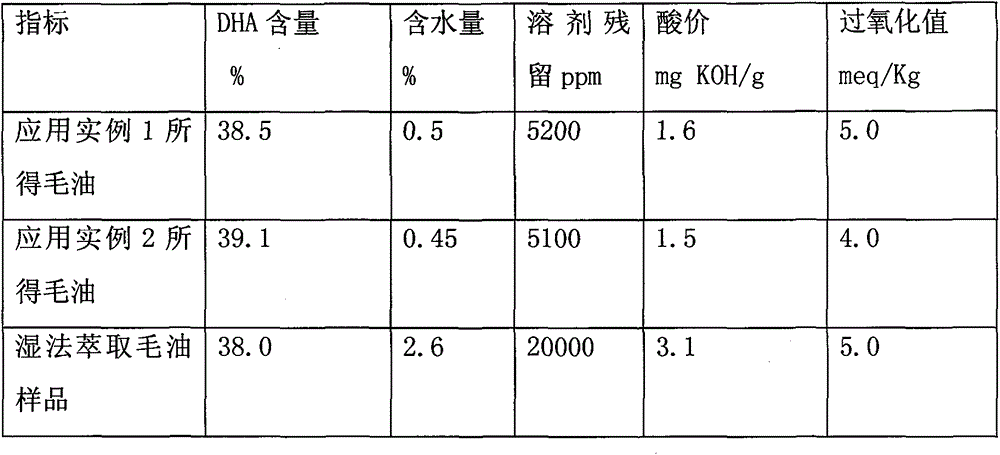

A method for ordinary pressure continuous extraction of grease from schizochytrium limacinum cake and equipment thereof are disclosed. The invention discloses a method for extracting residual grease from schizochytrium limacinum cake at ordinary pressure by using n-hexane. The method is characterized in that pelletized or puffed schizochytrium limacinum dry mycelium or oil-pressed cake which is used as a raw material undergoes continuous extraction in an n-hexane solvent by reflux and full immersion modes under ordinary pressure by the utilization of a specially-designed immersion-type extractor so as to obtain grease in the schizochytrium limacinum cake. The specially-designed immersion-type extractor is a shallow-bed type. An embedded scraper and a continuous-type tray are arranged inside the extractor. The solvent moves in the reverse direction of the feed scraper. During the whole extraction process, it can be guaranteed that the raw material is completely immersed in the solvent until extraction and slag emission are completed. By the design and the extraction technology, continuous production can be realized, extraction efficiency is improved, and extraction cost is reduced. The equipment of the invention is more excellent than existing subcritical and supercritical extraction technological equipment.

Description

technical field [0001] This patent relates to a submerged extraction technology of Schizochytrium cake and the design of the extraction equipment, which is mainly an industrial method for extracting oil from Schizochytrium cake by using a solvent under normal pressure. Background technique [0002] Microbial fats are the third emerging source of edible fats besides animal fats and vegetable fats. In particular, some n3 functional polyunsaturated fatty acids that are not found in animal and vegetable fats can be obtained from microbial fats, such as DHA and ARA. Polyunsaturated fatty acids play an important role in the visual and intellectual development of infants and young children. Therefore, the technology of obtaining functional polyunsaturated fatty acids from microorganisms has important industrial and market value. Various microorganisms, including Schizochytrium, have been successfully applied and industrialized, and achieved good economic benefits. [0003] At pres...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C11B1/10C11B1/02

Inventor 朱蓓微王兴国金青哲王永富

Owner 青岛海智源生命科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com