Negative pressure wind pipe

A negative pressure air and cylinder technology, which is applied in the direction of pipeline layout, ventilation system, space heating and ventilation, etc., can solve the problems of deflation, affecting the use of air ducts, and easy bending of textile air ducts, so as to prevent bending and other problems. Folding and shrinking, increasing stability, and beneficial to ventilation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

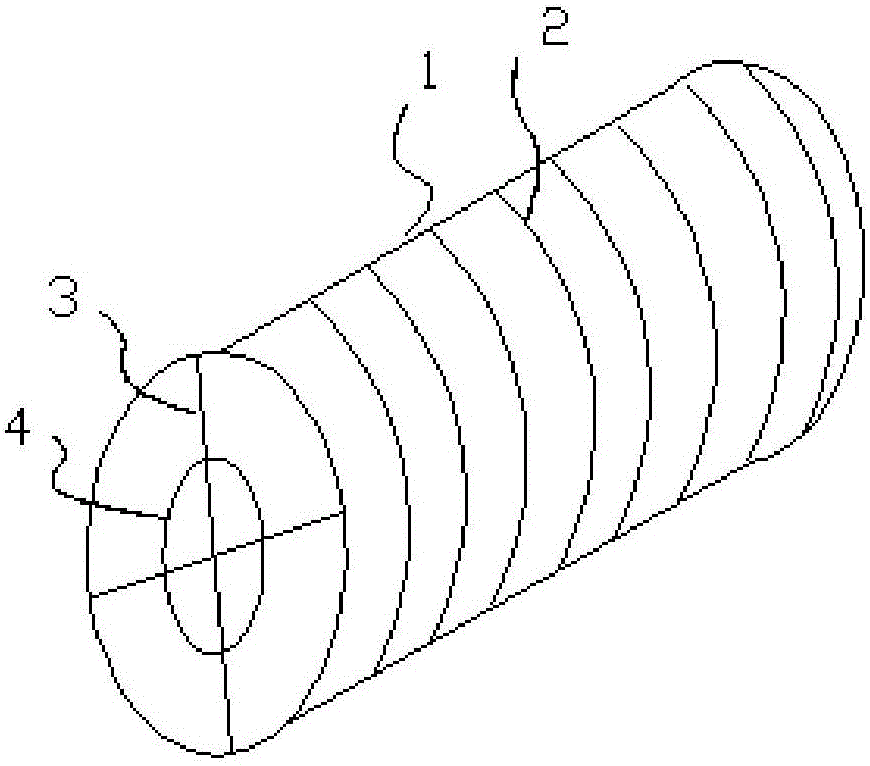

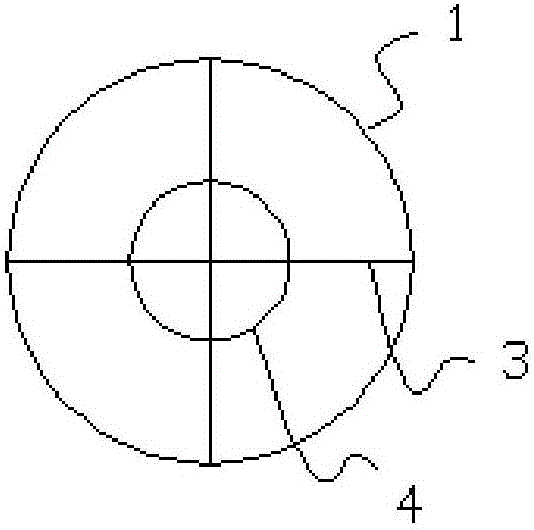

[0017] Such as figure 1 , figure 2 As shown, the structure of this kind of negative pressure air duct includes a cylinder body 1 made of existing textile cloth, and the outer surface of the cylinder body 1 is screw-fixed with a bracket 2 along the axial direction. When in use, the bracket can support the side wall of the cylinder, provide support for the negative pressure behind, and prevent the problems of bending and suction.

[0018] In the above embodiment, specifically, the inner surface of the cylinder body 1 is provided with reinforcing brackets 3 crossed, and the outer ends of the reinforcement brackets 3 are perpendicular to the tangent line where the inner surface of the cylinder body 1 is located. The reinforcing bracket 3 is provided with a reinforcing ring 4 . When in use, the reinforcing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com