Fault detection method and device for principal component correlation degree sensor based on density clustering

A technology of sensor failure and density clustering, which is applied in the direction of instrumentation, computing, character and pattern recognition, etc., can solve problems such as difficulty in detecting sensor failure, economic loss, and performance degradation of the control system, and achieve the effect of fast and accurate fault diagnosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

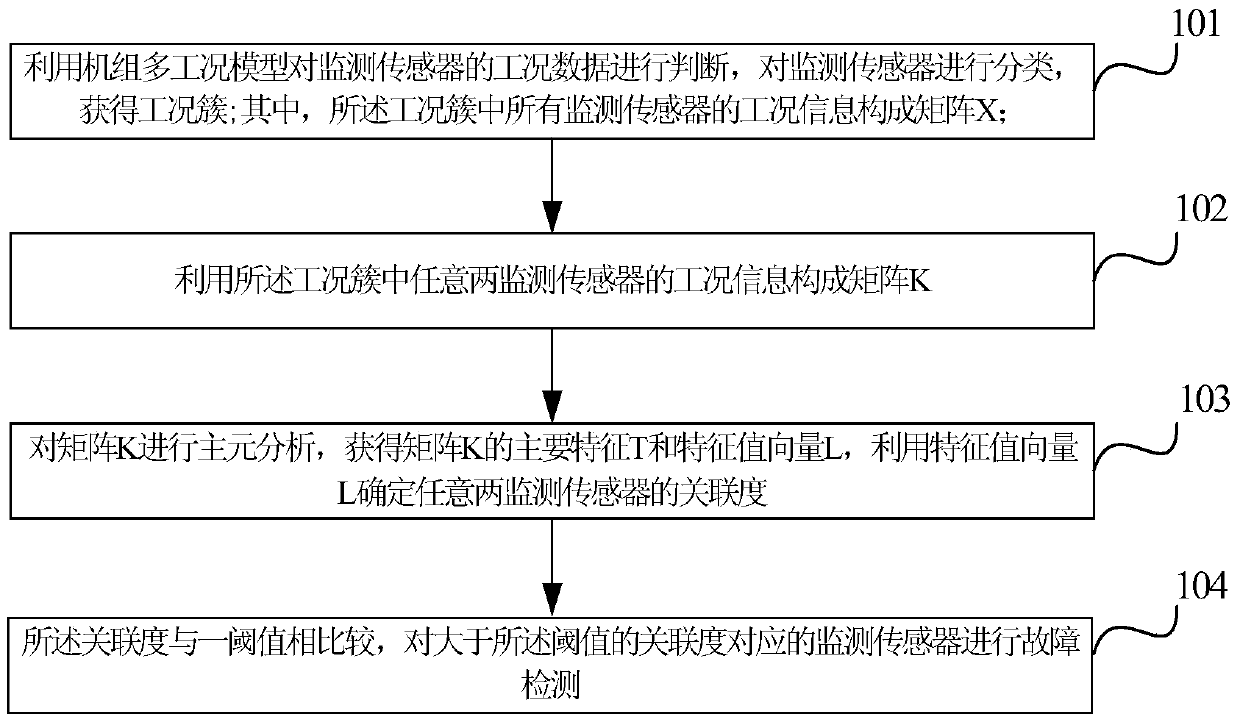

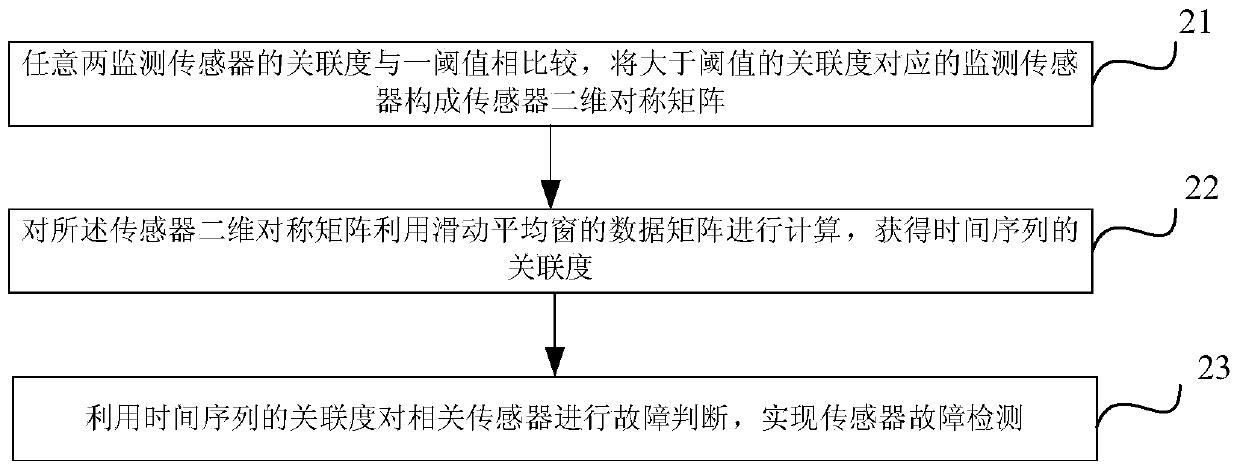

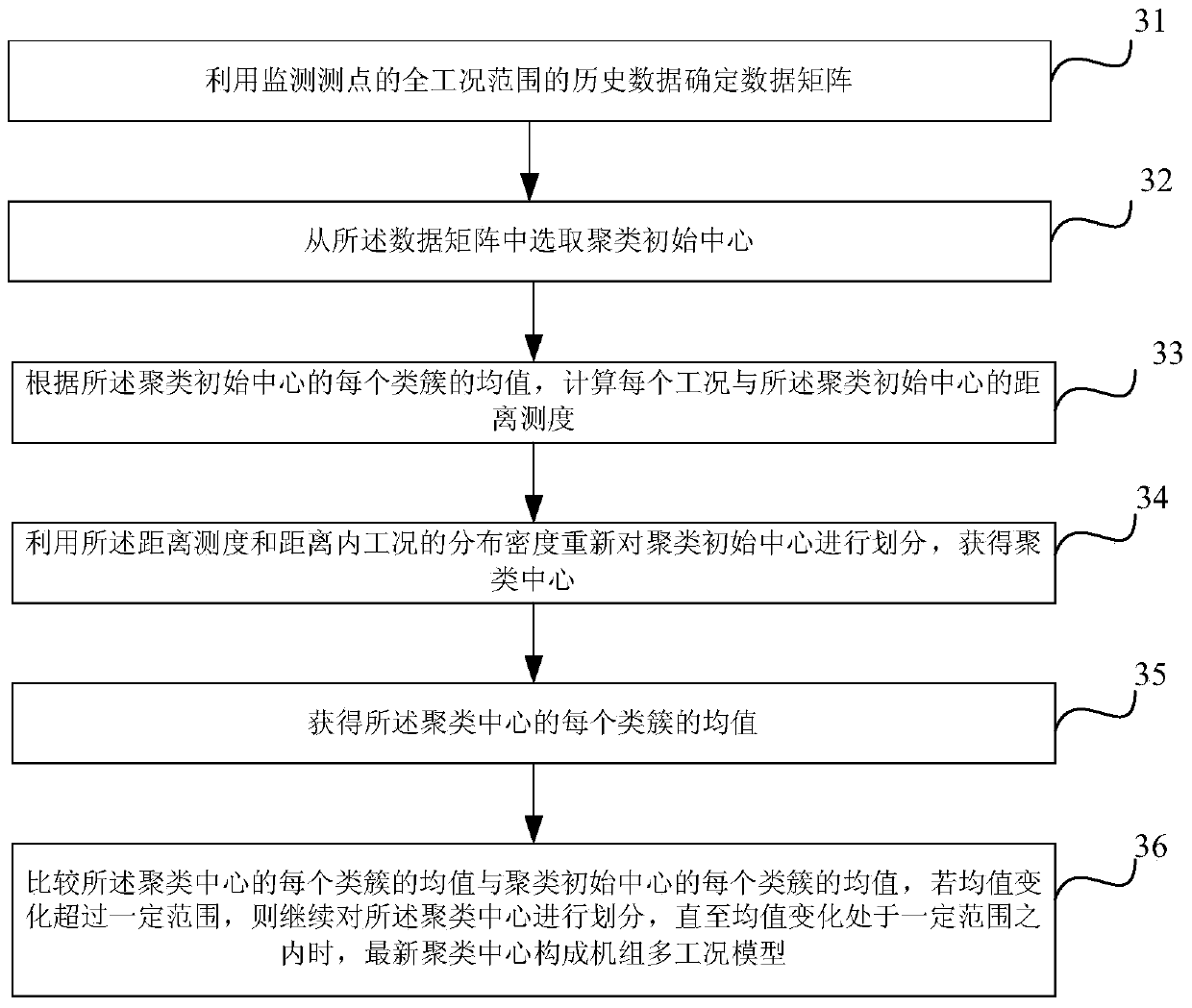

Method used

Image

Examples

Embodiment

[0095] Randomly select all measuring points within a certain period of time for clustering, and divide them into several typical working condition clusters. 500 sets of data are used as the fixed time window length, and the last 500 sets of data are used as test data. In this case, the test data is superimposed with 5% deviation fault data, and the average length of the sliding window is selected as 5. After combining the fixed window and the sliding window, real-time Computes the correlation between the measured points within the window.

[0096] exist Figure 7 ~ Figure 11 In , the meaning expressed by the axis of ordinate is: the correlation degree between measuring points, and the meaning expressed by the axis of abscissa is; time series. For example: 1 represents time 1, 2 represents time 2, and so on.

[0097] Figure 7 It is the change curve of the correlation between measuring point 1 and measuring point 2. It can be seen that the correlation between measuring point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com