Lithium battery winding core, mobile phone battery, mobile phone and manufacturing method thereof

A mobile phone battery and lithium battery technology, which is applied in the fields of mobile phone batteries, lithium battery cores, mobile phones and their production, can solve the problems of wasted space, connection gaps, etc., and achieve the effect of avoiding waste and eliminating gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

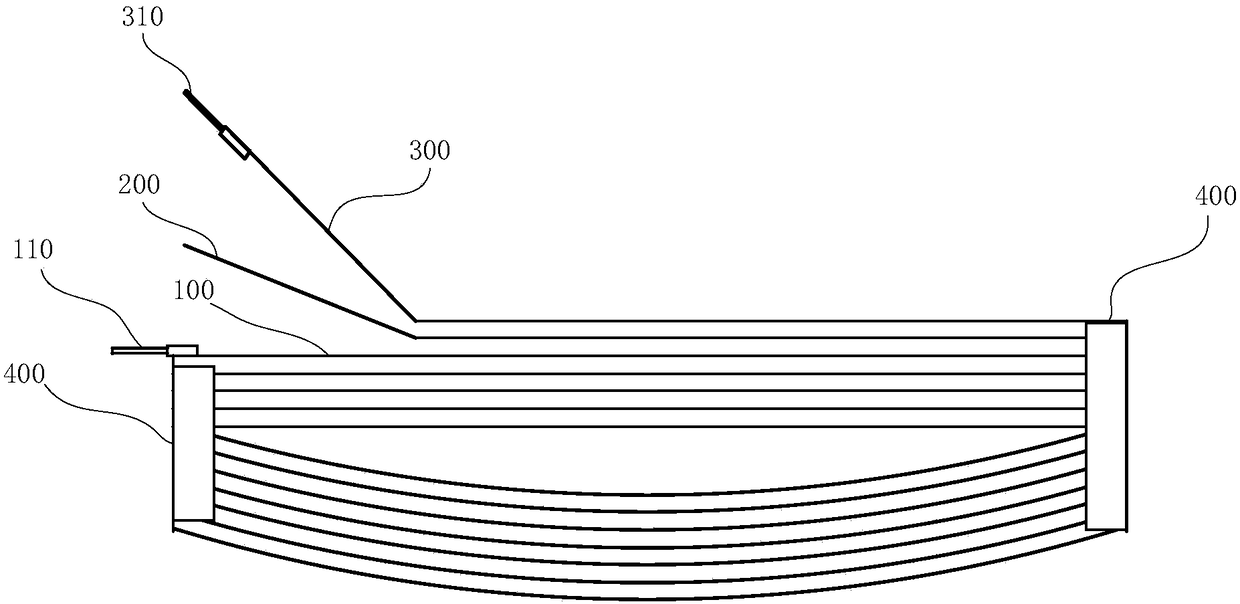

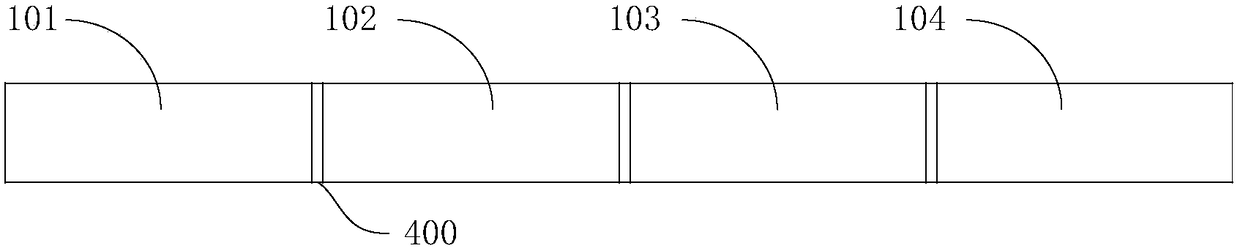

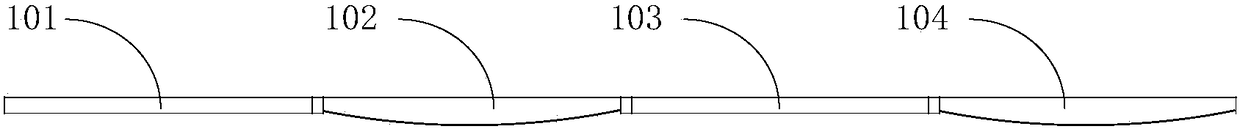

[0038] A winding core of a lithium battery, such as figure 1 Shown, including:

[0039] The positive electrode sheet 100, the separator 200, and the negative electrode sheet 300; the separator 200 is disposed between the positive electrode sheet 100 and the negative electrode sheet 300.

[0040] The stack of the positive electrode sheet 100, the separator 200 and the negative electrode sheet 300 is formed into a winding core by a winding method, and the winding core has a curved surface on one side and a flat surface on the other side. In other embodiments, both surfaces may be curved. The curved surface may be a curved surface, the curved surface may be a regular curved surface or an irregular curved surface, and it can be made or designed according to the shape of the mobile phone.

[0041] The stack of the positive electrode sheet 100, the negative electrode sheet 300 and the separator 200 includes an odd-numbered layer and an even-numbered layer.

[0042] Optionally, a positive e...

Embodiment 2

[0055] A mobile phone battery includes the winding core of the lithium battery in Example 1.

[0056] Such as Image 6 As shown, the mobile phone battery further includes a casing 500, which has been shaped into a curved surface and fitted with the curved surface of the core of the lithium battery.

[0057] The surface of the cell phone battery connected with the cell phone shell is a curved surface; the surface connected with the main board of the cell phone is a flat surface.

[0058] The mobile phone battery of this embodiment also includes a positive electrode coating and a negative electrode coating, which improves the activity of the positive and negative electrodes, thereby improving the storage capacity and performance of the mobile phone battery. At the same time, the mobile phone battery is prepared by using the lithium battery core described in Example 1 through curved surface shaping, which facilitates curved surface shaping and facilitates the formation of a lithium bat...

Embodiment 3

[0060] A method for manufacturing a lithium battery, used to manufacture the lithium battery in Example 2, includes the following steps:

[0061] S100: The stack of positive electrode sheets, separators and negative electrode sheets laid in sequence is wound to form a winding core;

[0062] Before forming the core by winding, in order to make the positive electrode ear and the negative electrode ear more stable and prevent them from falling off, tape can be attached to the riveted joint between the positive electrode ear and the positive electrode sheet, and the negative electrode ear and the negative electrode Adhesive tape is attached to the riveting part of the sheet.

[0063] S200: placing the winding core in a set packaging film, pouring electrolyte solution, and sealing to form a single battery;

[0064] The packaging film is composed of three layers of polypropylene film, aluminum foil and nylon film to form a composite film. Wherein, the nylon membrane can be replaced with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com