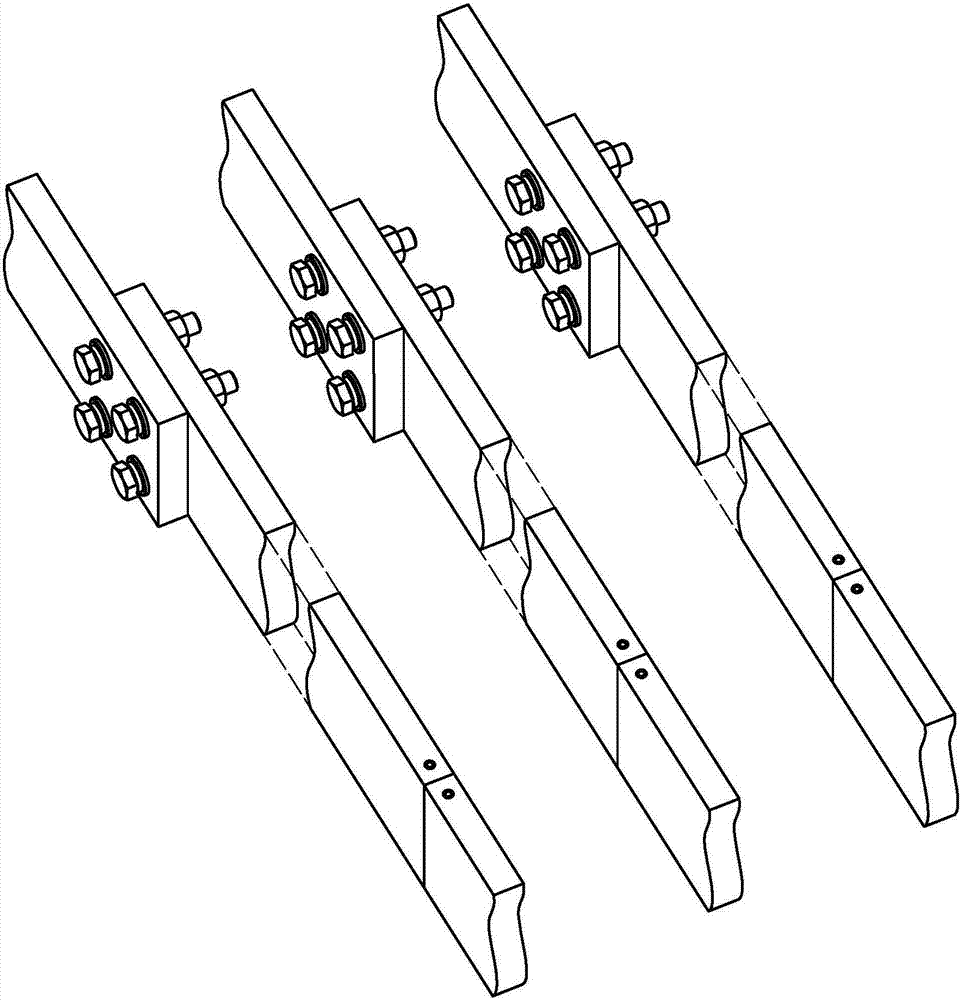

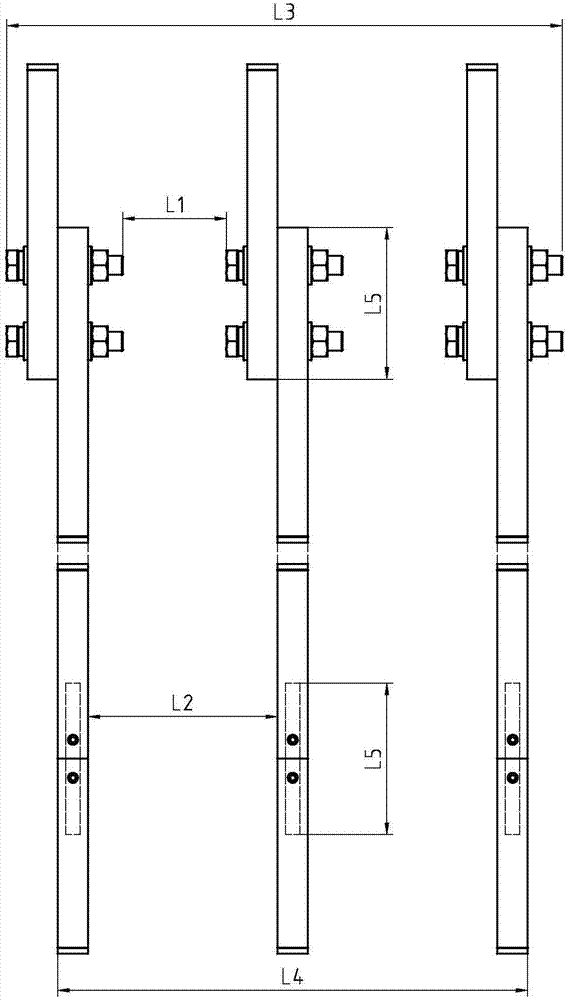

Construction method for reducing the temperature rise at the lap joint of electrical busbars

A technology of busbar lap connection and construction method, applied in the direction of cooling busbar devices, etc., can solve the problems of reducing electrical clearance or interphase distance, increasing equipment manufacturing cost, and increasing the space occupied by busbars, so as to increase the electrical clearance or phase-to-phase distance, etc. The effect of distance, saving resources, reducing wiring width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

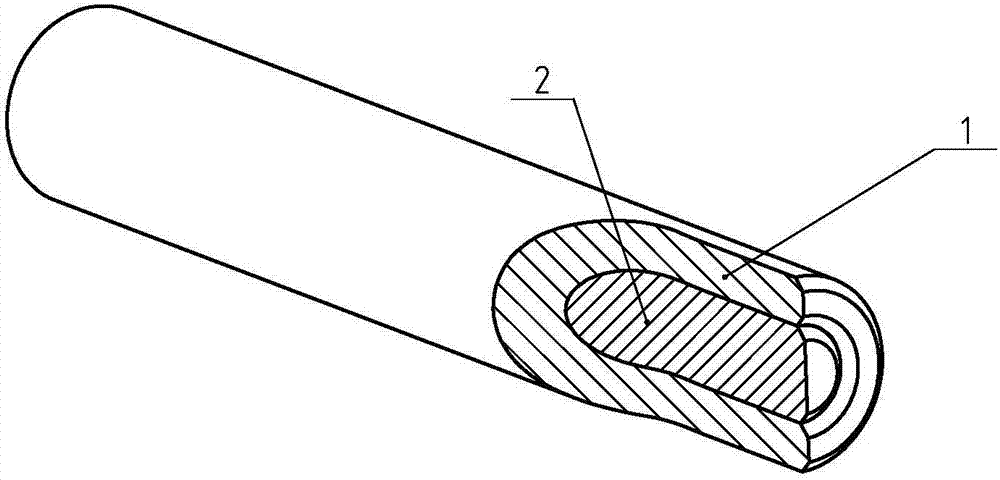

Embodiment 2

[0084] Change the copper tube in Example 1 into a copper alloy tube, and change the aluminum rod into an aluminum alloy rod. Because the hardness of the alloy is relatively high, the aluminum alloy rod can be stored for a period of time (5 minutes) in a low temperature environment (5 degrees). ), and the copper alloy tube is stored in a high temperature environment (80 degrees) for a period of time (5 minutes), with the help of thermal expansion and contraction effect, the inner diameter of the copper alloy tube can be slightly larger, while the outer diameter of the aluminum alloy rod is slightly smaller , and then conveniently assemble the aluminum alloy rod into the copper alloy tube. After the assembled connecting column returns to normal temperature, the copper alloy tube and the aluminum alloy rod can achieve interference fit. The diameter and length of the coupling column disclosed in the present invention have different specifications to meet the needs of different busb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com