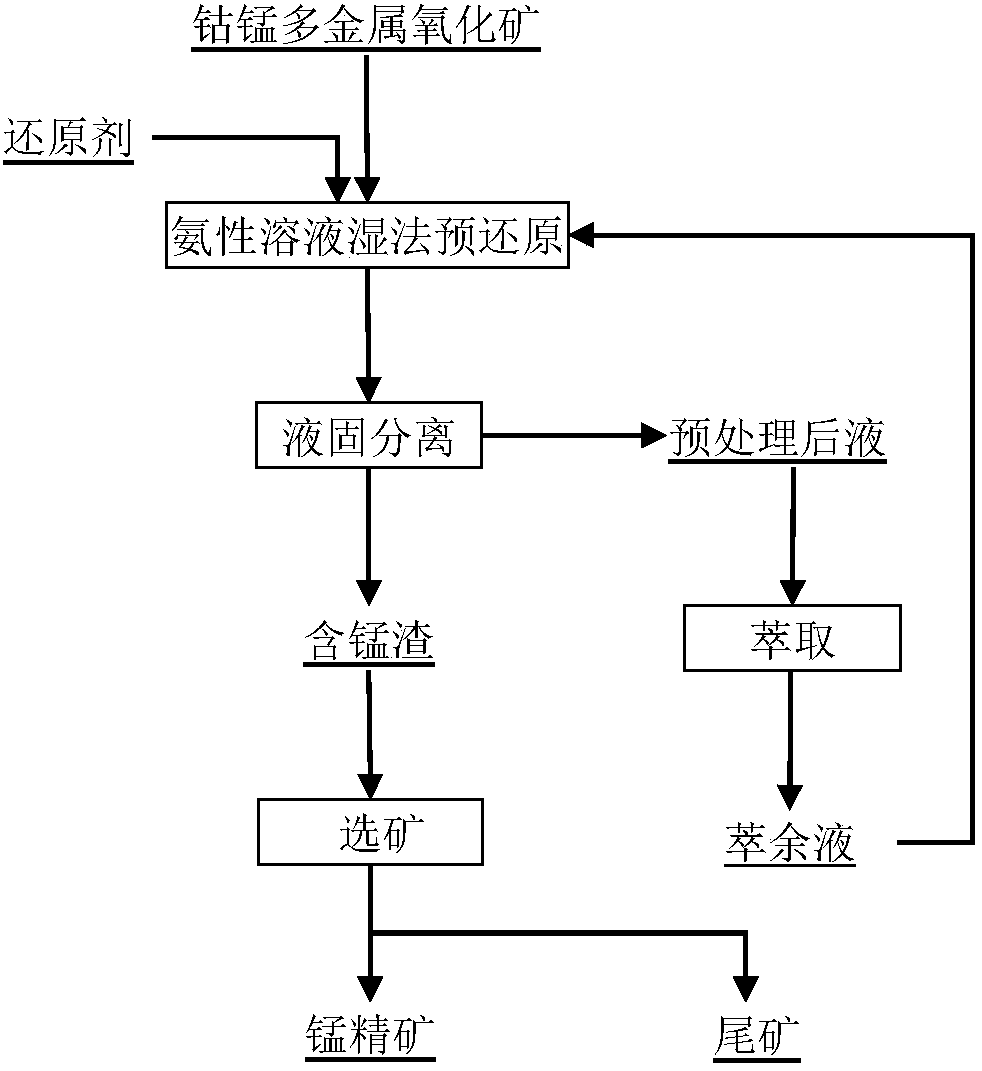

Method for recovering manganese from cobalt manganese polymetallic oxide ore

A technology for polymetallic oxide ore, cobalt and manganese, applied in the field of wet reduction pretreatment, beneficiation and recovery of manganese, can solve the problems of complex comprehensive recovery process, low manganese content and high cost, and achieve good separation effect, high manganese recovery rate, Good quality product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add the cobalt-manganese polymetallic oxide ore into the ammonia-ammonium carbonate solution with a total ammonia concentration of 120g / L and stir. After mixing evenly, add an appropriate amount of cuprous salt to the pulp and pass it into carbon monoxide for reduction treatment for 4 hours. Separation of solid and liquid to obtain manganese-containing slag and pretreated liquid. After pretreatment, the liquid is extracted and separated from valuable elements such as nickel, cobalt, and copper, and then returned to reduction leaching for use. Add water to the manganese-containing slag to prepare a 35% pulp, add sulfuric acid solution to adjust the pH of the pulp to 8-9, and then add 2.8kg of water glass / t slag, 2.5kg sodium oleate / t slag, after being stirred for 5 minutes, enter the flotation machine, after primary separation, the yield of manganese concentrate is 63.4%, the manganese content is 37.2%, and the total iron content is 1.5%.

Embodiment 2

[0023] Add the cobalt-manganese polymetallic oxide ore into the ammonia-ammonium sulfate solution with a total ammonia concentration of 80g / L and stir. After mixing evenly, add an appropriate amount of cuprous salt to the slurry and pass it into carbon monoxide for reduction treatment for 2 hours. Separation of solid and liquid to obtain manganese-containing slag and pretreated liquid. After pretreatment, the liquid is extracted and separated from valuable elements such as nickel, cobalt, and copper, and then returned to reduction leaching for use. Add water to the manganese-containing slag to prepare a 35% pulp, add sulfuric acid solution to adjust the pH of the pulp to 8-9, and then add 2.8kg of water glass / t slag, 2.5kg sodium oleate / t slag, after stirring for 5 minutes, it enters the flotation machine. After primary selection, the yield of manganese concentrate is 62.6%, the manganese content is 35.9%, and the total iron content is 1.3%.

Embodiment 3

[0025] Add the cobalt-manganese polymetallic oxide ore into the ammonia-ammonium sulfate solution with a total ammonia concentration of 60g / L and stir. After mixing evenly, add an appropriate amount of cuprous salt to the pulp and pass it through carbon monoxide for reduction treatment for 4 hours. Separation of solid and liquid to obtain manganese-containing slag and pretreated liquid. After pretreatment, the liquid is extracted and separated from valuable elements such as nickel, cobalt, and copper, and then returned to reduction leaching for use. Add water to the manganese-containing slag to prepare a 35% pulp, add sulfuric acid solution to adjust the pH of the pulp to 8-9, and then add 2.8kg of water glass / t slag, 2.5kg sodium lauryl sulfate / t slag, after stirring for 5 minutes, enter the flotation machine, after a primary separation, the yield of manganese concentrate is 61.4%, the manganese content is 35.5%, and the total iron content is 1.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com