A squeegee device for automatic gluing machine

A technology of a squeegee device and a glue applicator, which is applied in the field of glue applicators, can solve the problems of poor squeegee effect, unfavorable large-scale production and processing, and high processing costs, saving manpower and positioning time, good squeegee effect, The effect of improving processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

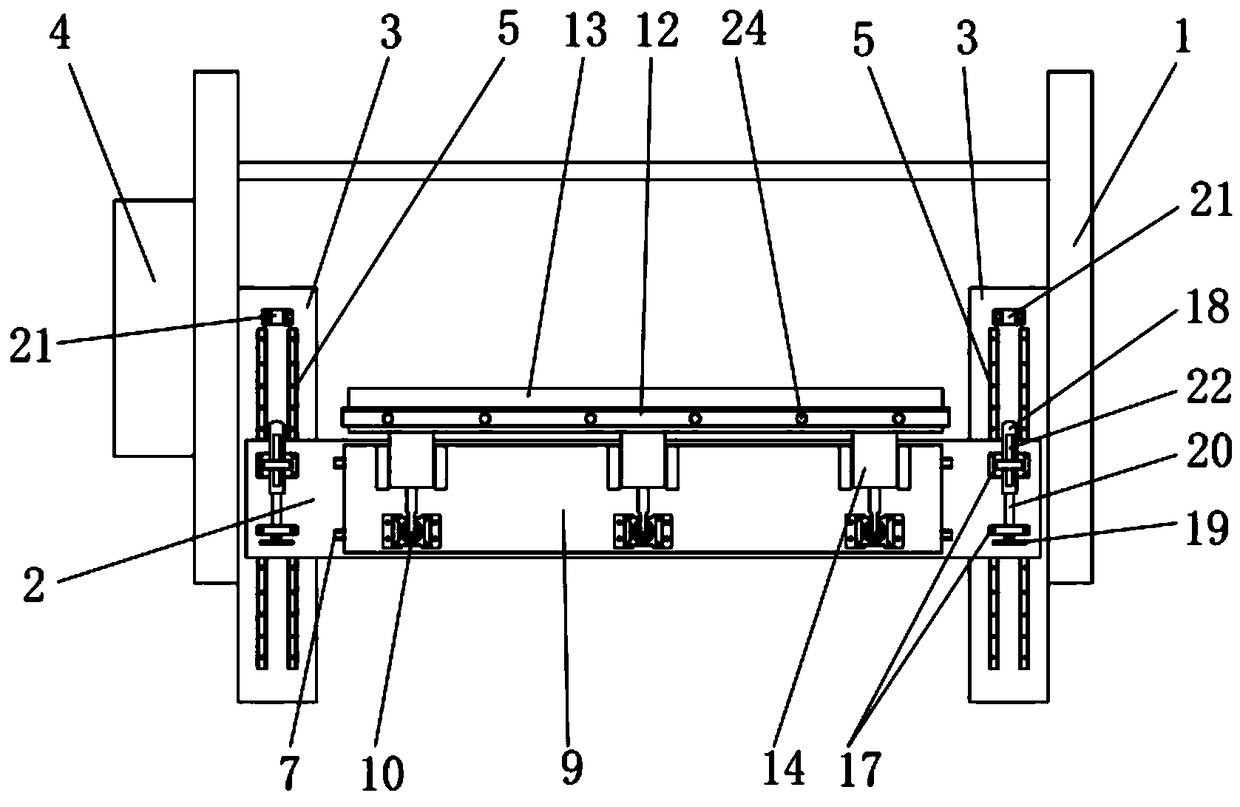

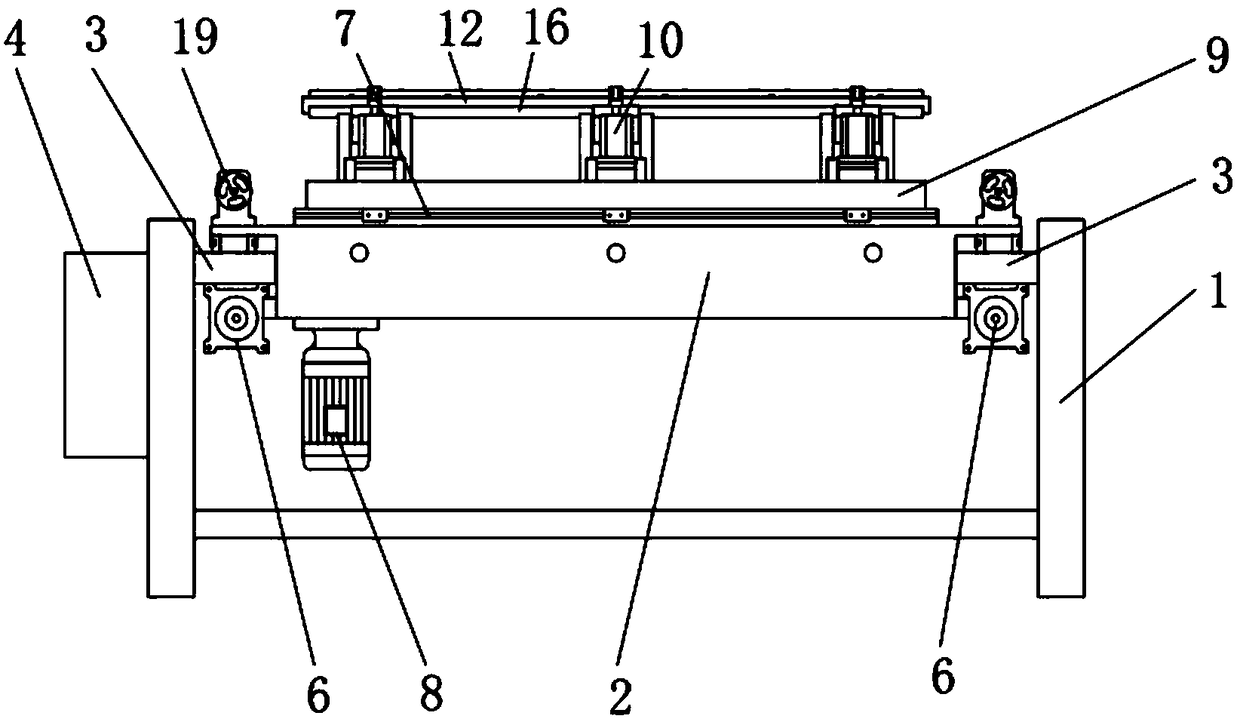

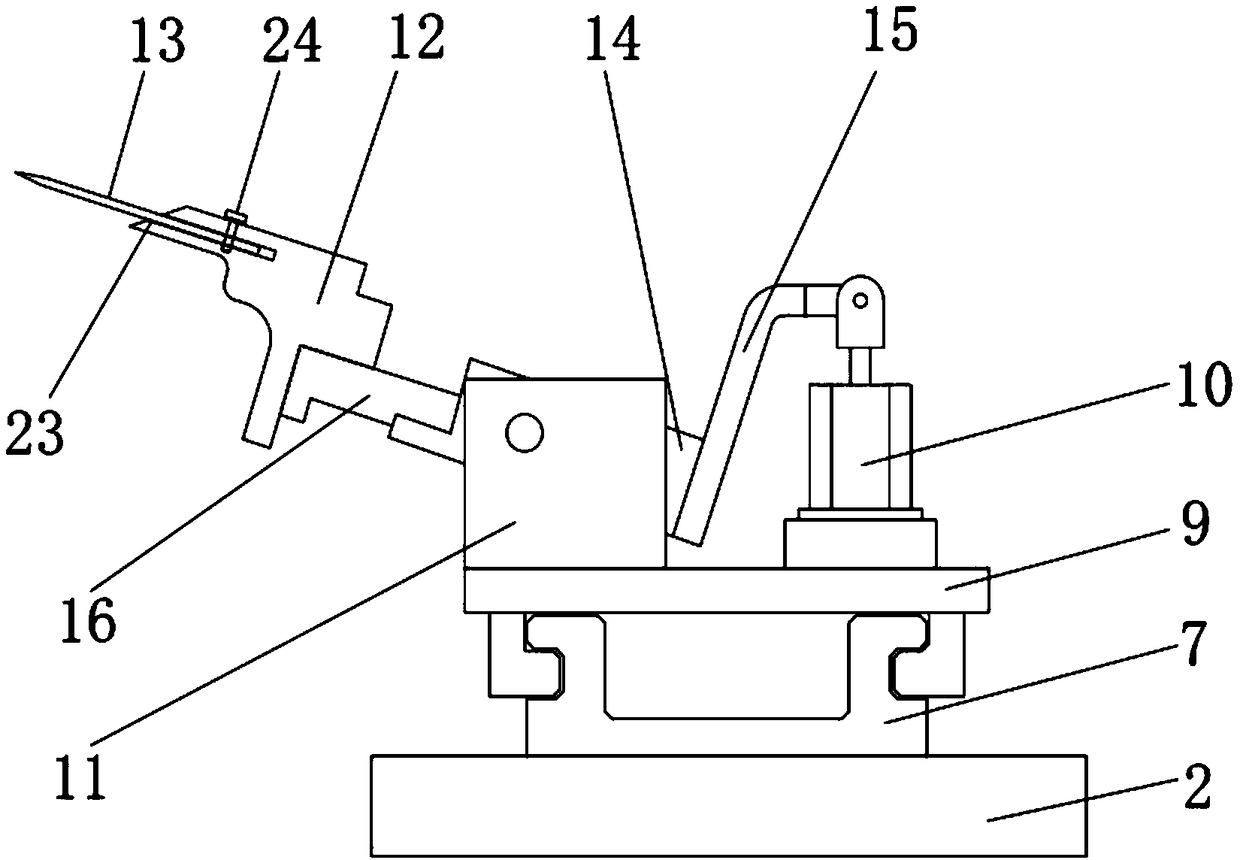

[0021] A glue scraping device for an automatic glue coating machine according to the present invention, such as Figure 1 to Figure 3 As shown, it includes a frame 1, a scraping platform 2, a platform support plate 3 and an electric control box 4; the electric control box 4 is arranged on the side of the frame 1; the platform support plate 3 is symmetrically arranged on the frame 1 The inner side of the platform support plate 3 is provided with a propulsion guide rail 5, and a propulsion cylinder 6 is provided below; ; A set of sliding guide rails 7 are arranged on the rubber scraping platform 2, and a sliding driving motor 8 is arranged below; a sliding base plate 9 is arranged on the sliding guide rail 7; A scraper adjustment mechanism; the scraper adjustment mechanism includes: an adjustment cylinder 10, an adjustment bracket 11, a scraper fixing plate 12 and a scraper 13; the adjustment bracket 11 is provided with a rotating plate 14; the rotating plate 14 is connected by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com