Manual rhinestone detaching device

A lifting device and rack technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as the inability to unload small-sized rhinestones, and achieve good popularization and application value, novel structure design, simple and efficient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

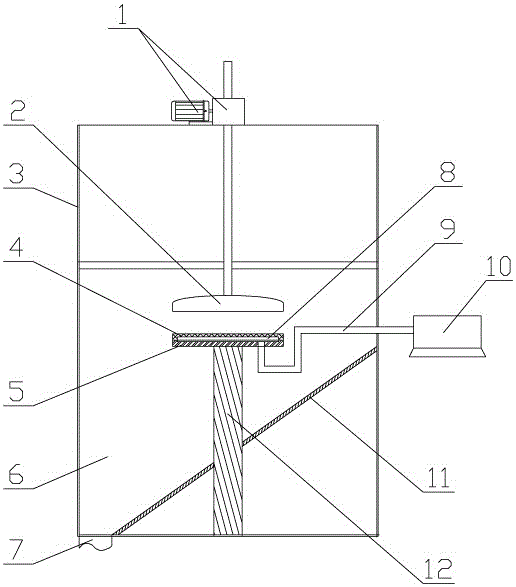

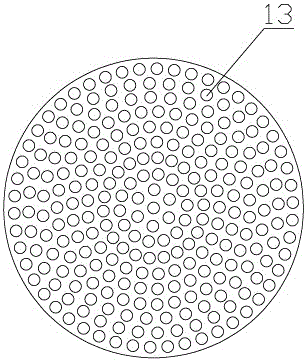

[0012] see figure 1 , figure 2 , the present invention is a manual drill unloading device, which has a box-shaped frame 3, the lower half of the box-shaped frame is a hopper 6, and a lifting device 1 is arranged on the top of the box-shaped frame, and the lifting device is vertically downward An electric heating plate 2 is connected, and a column 12 is arranged directly below the electric heating plate. A plurality of air holes 13 are arranged on the plate, and an air cavity 8 is sealed between the porous plate and the steel chassis. A vacuum tube 9 is arranged on the steel chassis, one end of the vacuum tube passes through the steel chassis and communicates with the air chamber, and the other end of the vacuum tube is connected with a vacuum pump 10 .

[0013] The perforated plate 4 in this embodiment is a disk-shaped structure made of aluminum plate.

[0014] In the hopper described in this embodiment, a material baffle plate 11 is arranged obliquely under the steel chas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com