Manipulator capable of rotatably lifting

A technology of rotating lifting and manipulators, which is applied in the field of manipulators, can solve the problems of high maintenance cost and high price, and achieve the effects of high degree of automation, scientific and reasonable setting, and reliable transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

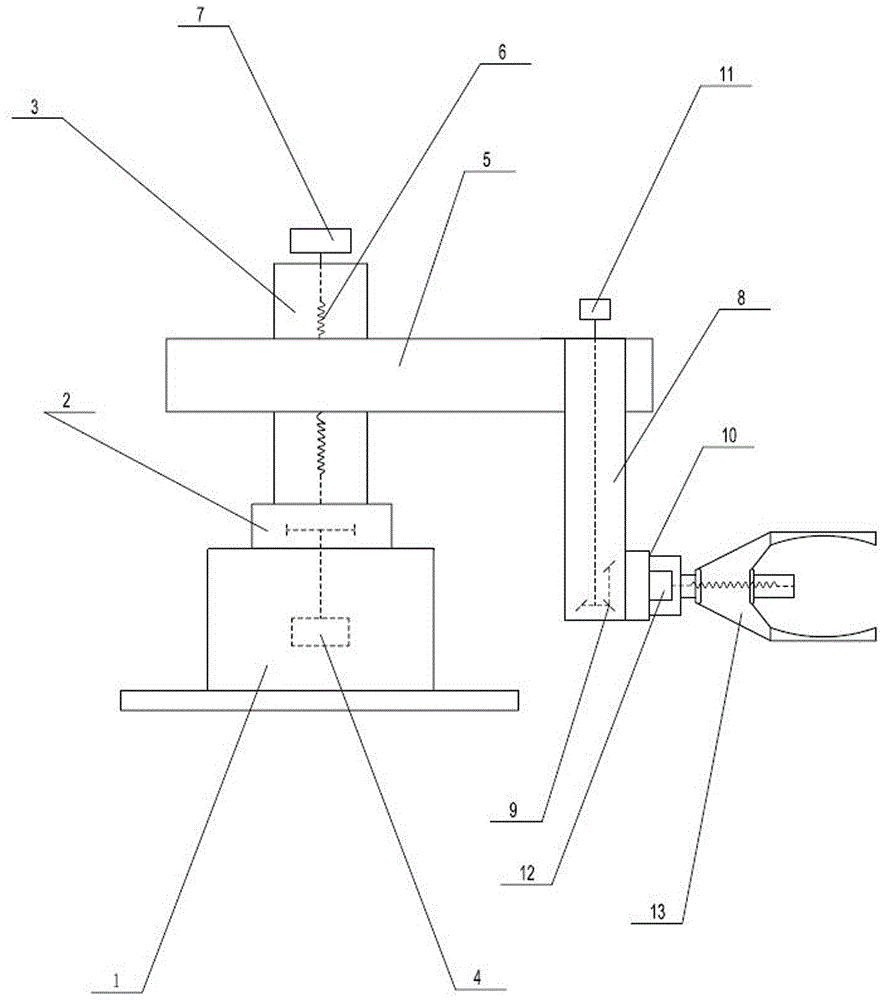

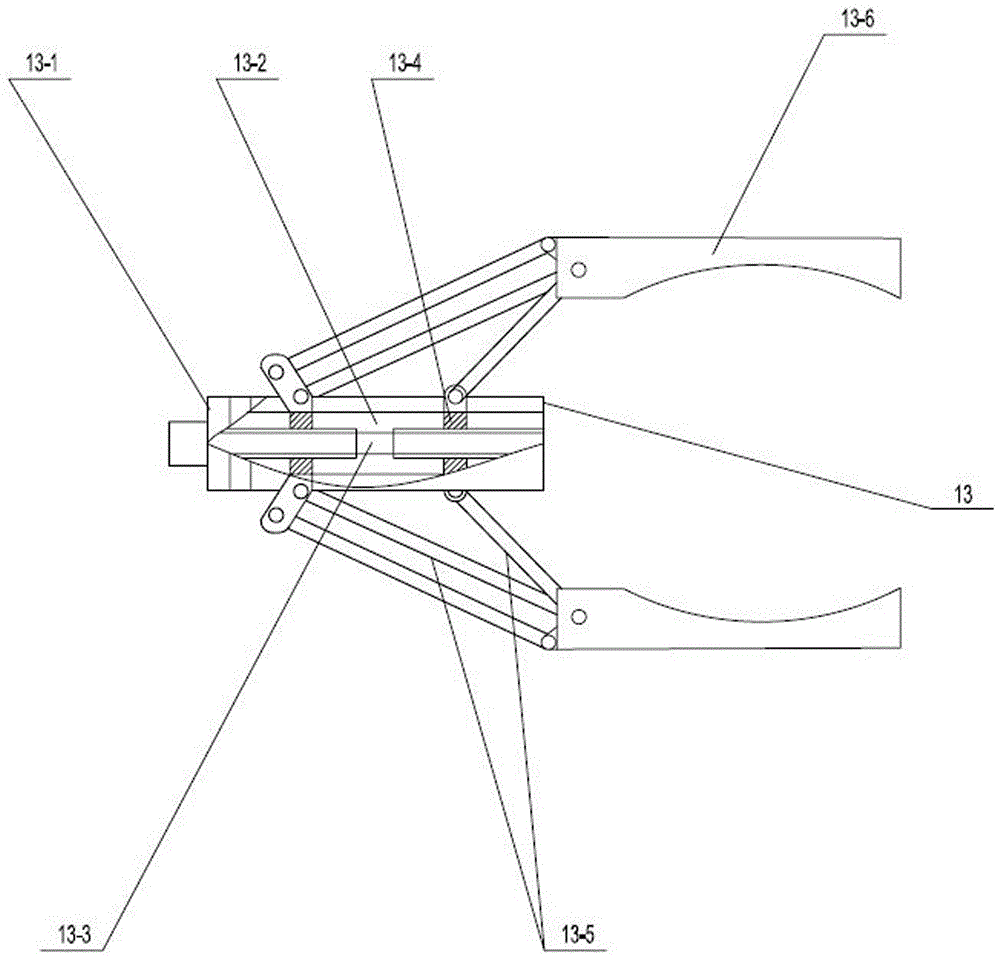

[0027] Such as figure 1 and figure 2 As shown, a rotatable lifting manipulator of the present invention is provided with a rotating waist plate 2 and a vertical arm 3 sequentially above the base 1, the gear on the rotating waist plate 3 and the first gear on the base 1 The rotating shafts of the drive 4 are meshed to realize circular rotation. The vertical arm 3 is installed vertically, and a cantilever 5 installed horizontally is provided on it. The lower side of the front end of the cantilever 5 is provided with a telescopic connector with one end fixed on the vertical arm 3. 6. The upper side is provided with a telescopic connector 6 with one end connected to the second drive 7. In this embodiment, a chute is set on the vertical arm 3, and the workbench connected to the cantilever 5 is placed in the chute, and the second drive 7 passes through the chute. The telescopic connector 6 moves up and down along the vertical arm 3 to realize the lifting of the cantilever 8. The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com