Deburring system for framework-containing rubber sealing ring

A technology for rubber sealing rings and deburring, which is applied in the field of sealing ring manufacturing, can solve problems such as difficulty in guaranteeing roundness, flatness, surface finish, non-compliance with requirements in the shape and position tolerance of sealing ring products, and easy deformation, etc. Reliability, reduce labor intensity, and ensure the effect of sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

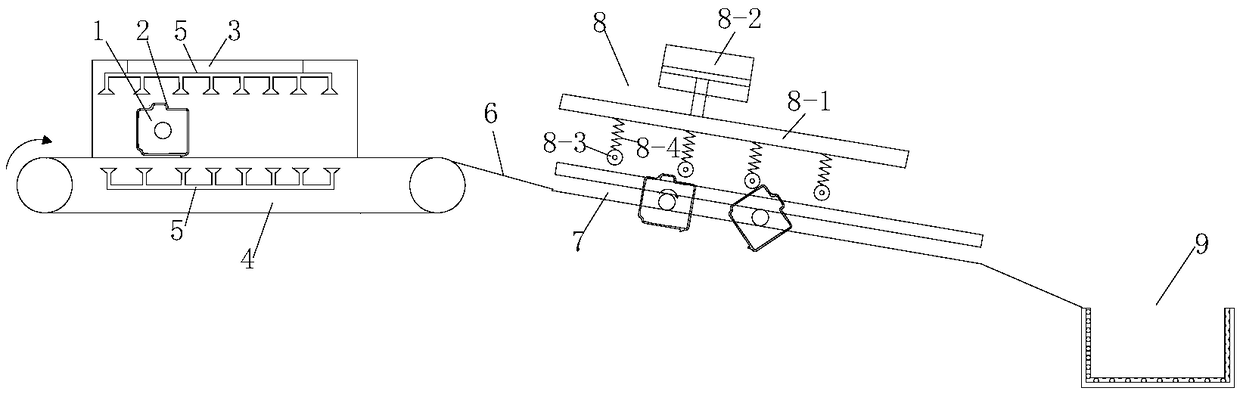

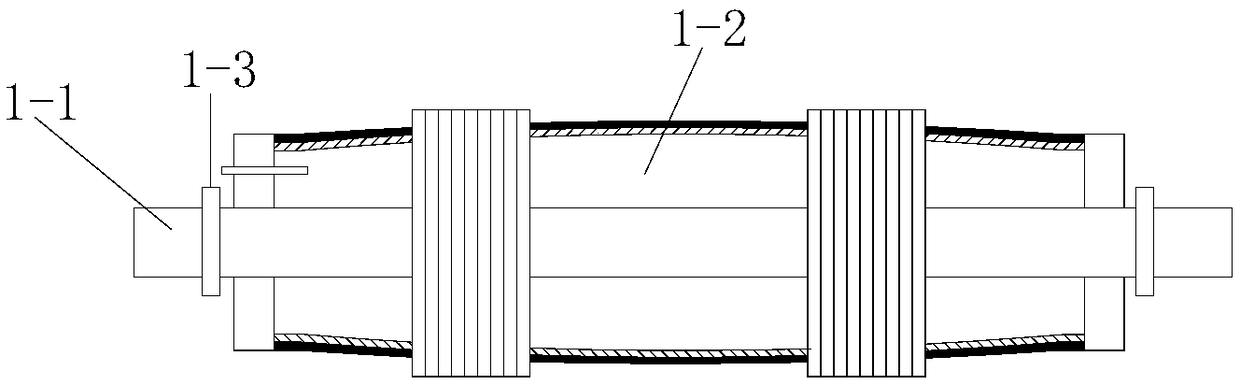

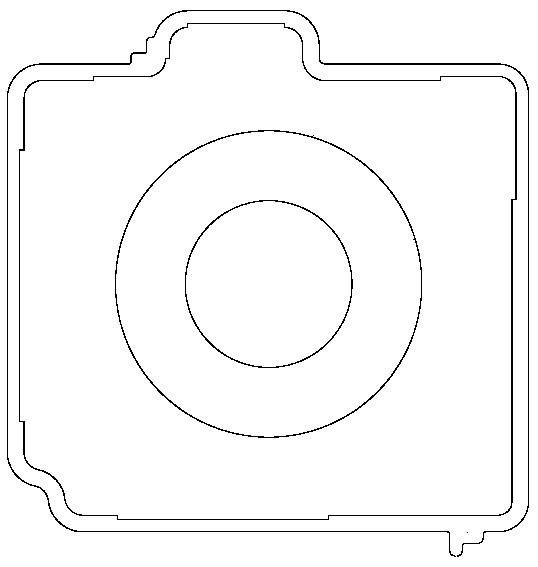

[0026] Such as figure 1 As shown, a rubber seal ring deburring system containing a skeleton includes a sleeve rod 1, which is used to socket and fix the seal ring 2 to be processed on the sleeve rod 1. The sleeve rod 1 includes: a rigid core rod 1 with a circular cross section -1, and the diameter reducing mechanism 1-2 arranged on the outside of the rigid core rod 1-1, the diameter reducing mechanism 1-2 supports and fixes the seal ring to be processed after expansion and diameter reduction, A bristle layer is provided on the surface of the contacting side of the circle;

[0027] The tunnel-type quick-freezing machine 3 includes: a tunnel cavity, the two ends of the tunnel cavity are respectively provided with a feed inlet and a discharge outlet, the bottom of the tunnel cavity is provided with a conveyor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com