High-speed dicer

A dicing machine, high-speed technology, applied in metal processing and other directions, can solve problems such as affecting the taste and appearance of processed meat pieces, low cutting efficiency, and high operating noise, so as to improve cross-cutting efficiency, improve dicing efficiency, and reduce operation. effect of noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

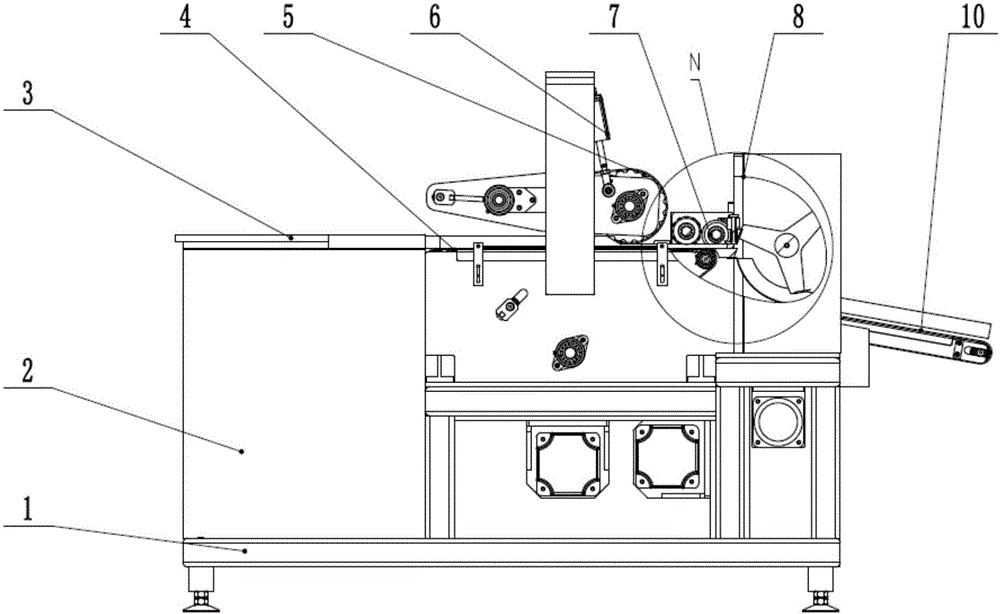

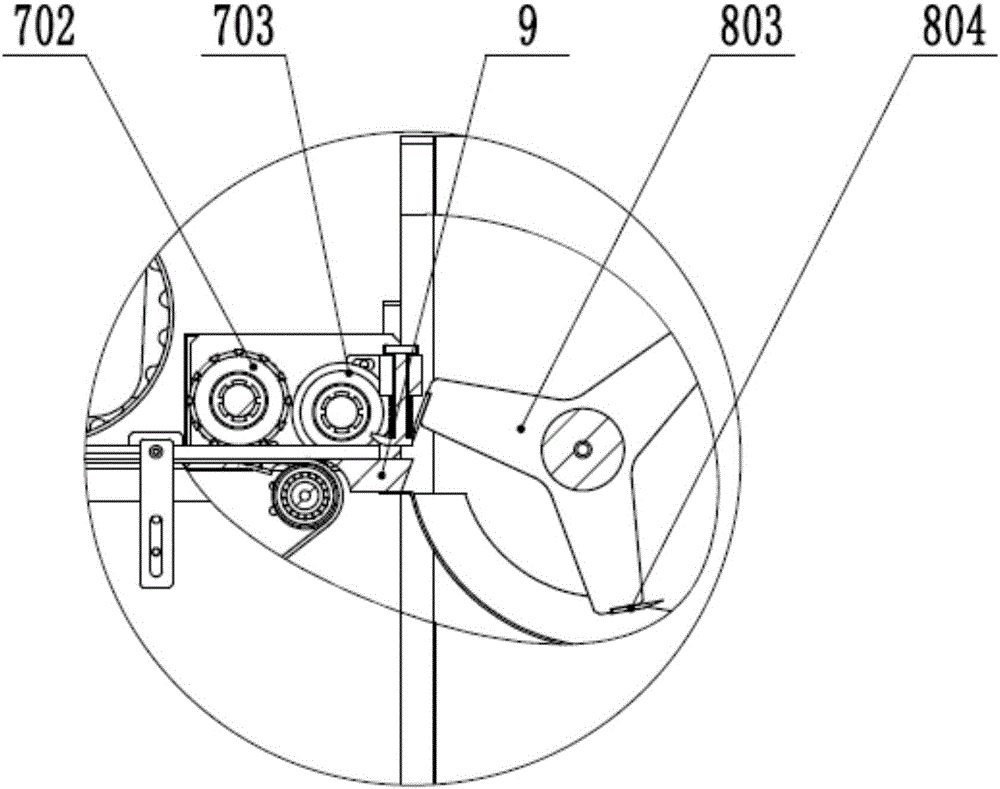

[0016] Such as figure 1 , 2 As shown, the high-speed dicing machine of the present invention includes a frame 1, an electric control box 2 fixed on the frame 1 and a feeding platform 3, and the feeding conveyor belt 4 is provided on the feeding platform 3, and the machine The frame 1 is also provided with an upper pinch belt 5 and a pressing cylinder 6, and the pressing cylinder 6 is connected with the upper pinch belt 5, and presses the upper pinch belt 5 to the feed conveyor belt 4; the feed conveyor belt 4 The downstream of the longitudinal strip cutting device 7 is provided with a horizontal cutting device 8 downstream of the longitudinal cutting device 7, and the bottom of the horizontal cutting device 8 is provided with a lower cutter 9, and the bottom of the lower cutting knife 9 is provided with There are meat diced output belt 10;

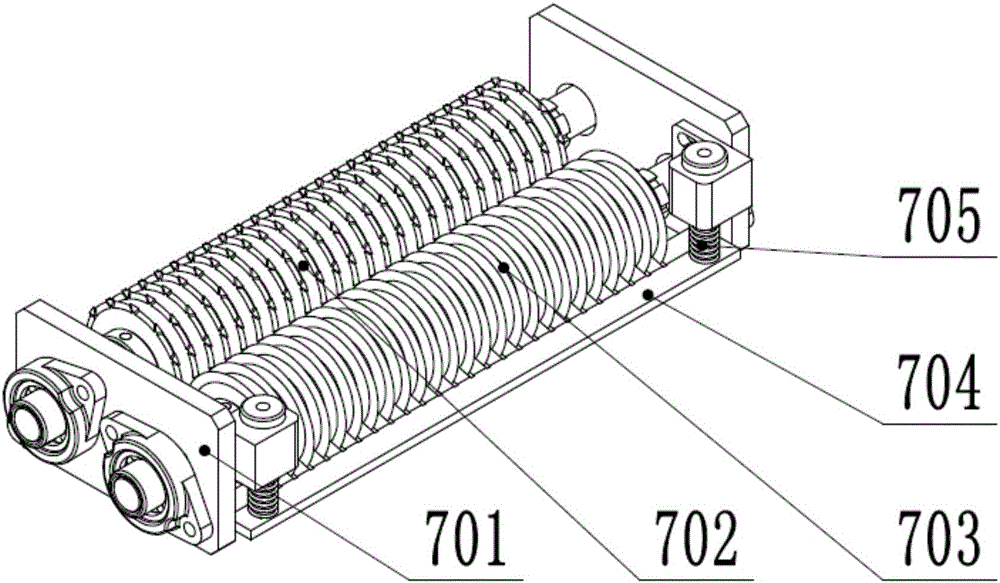

[0017] Such as image 3 As shown, the longitudinal strip cutting device 7 includes a longitudinal cutting device mounting plate 701, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com