Pearl embroidery fabric for clothes

A bead embroidery and fabric technology, applied in the field of bead embroidery fabrics, can solve the problem that bead embroidery fabrics are difficult to meet the requirements, and achieve the effects of high wear resistance, good fabric texture, and reasonable and novel structural design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

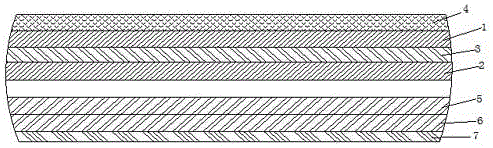

[0010] The technical characteristics of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0011] The present invention relates to a bead embroidery fabric for clothing, which comprises a fabric layer and a base layer. The fabric layer includes a nylon mesh layer I, a nylon mesh layer II, a fabric middle layer and a pearlescent cloth layer. The base layer includes a non-woven fabric layer I, a non-woven fabric layer Cloth layer II and fleece layer; the middle layer of the fabric is arranged between the nylon mesh layer I and the nylon mesh layer II; the non-woven layer I is bonded to the nylon mesh layer II, and the fleece layer is arranged on the non-woven layer On the outer surface of the cloth layer II, the pearl cloth layer is arranged on the outer surface of the nylon mesh layer I; the thickness of the nylon mesh layer I is 0.14 mm, the thickness of the nylon mesh layer II is 0.14 mm, and the midd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com