An electric printing head device

A printing head and electric technology, which is applied in the field of electric printing head device and marking device on the steel plate, can solve the problems of immature structure and unsatisfactory effect, achieve the forward punching and returning action simply, improve the durability, and the front Punch and return actions and high-speed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

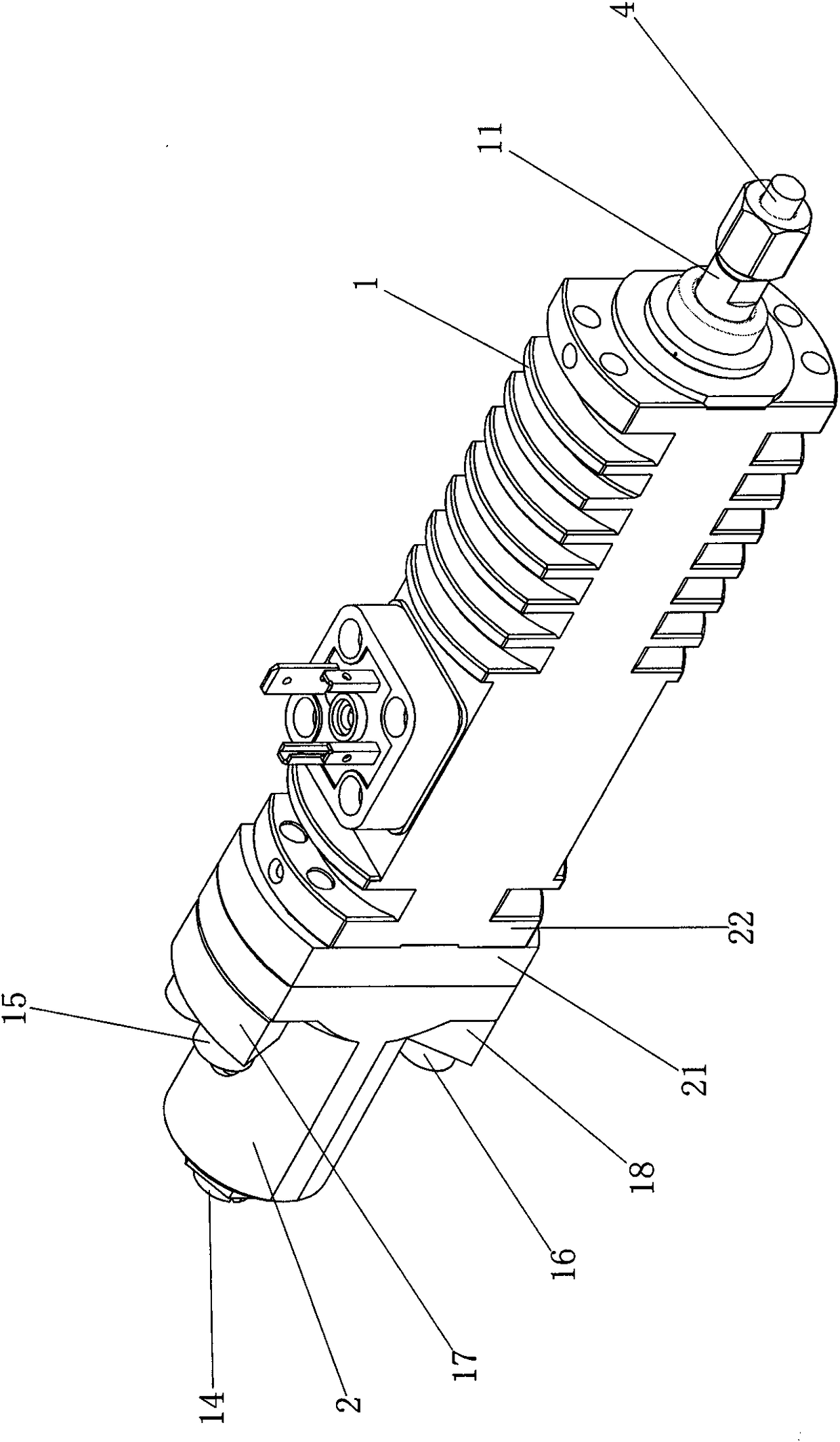

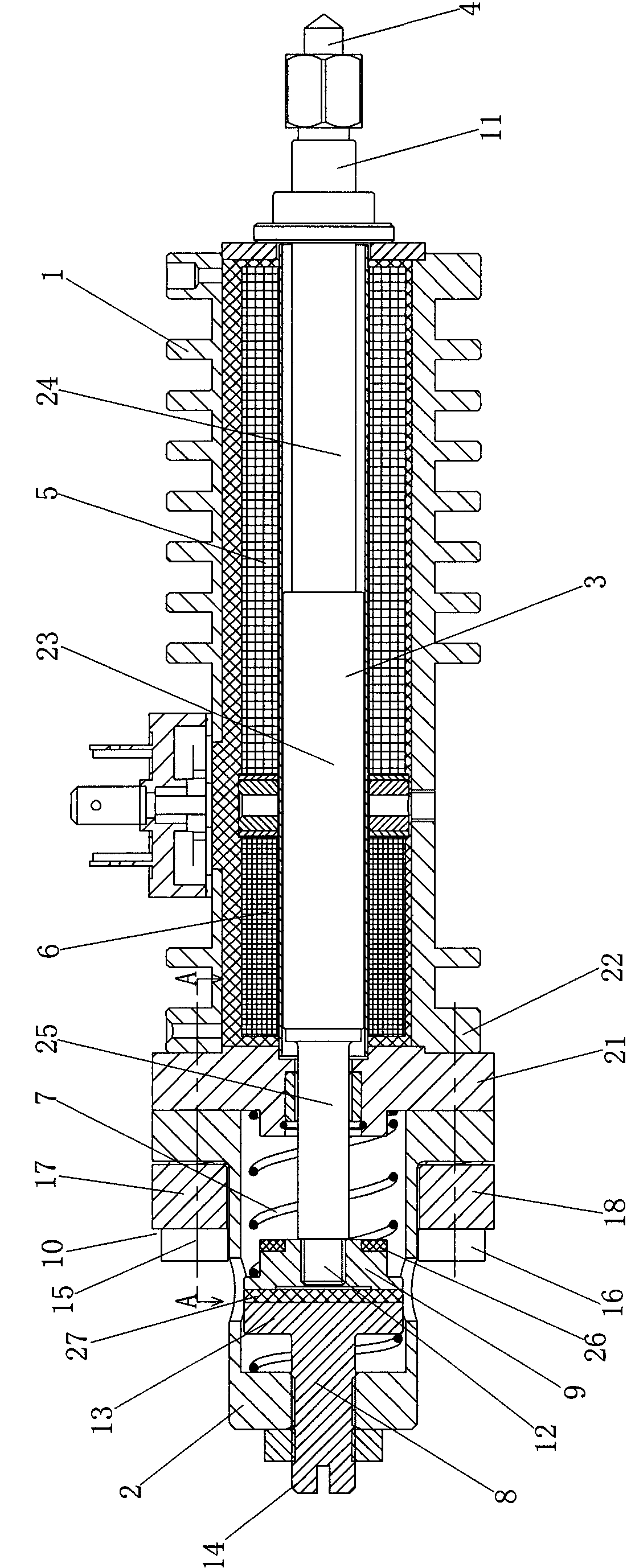

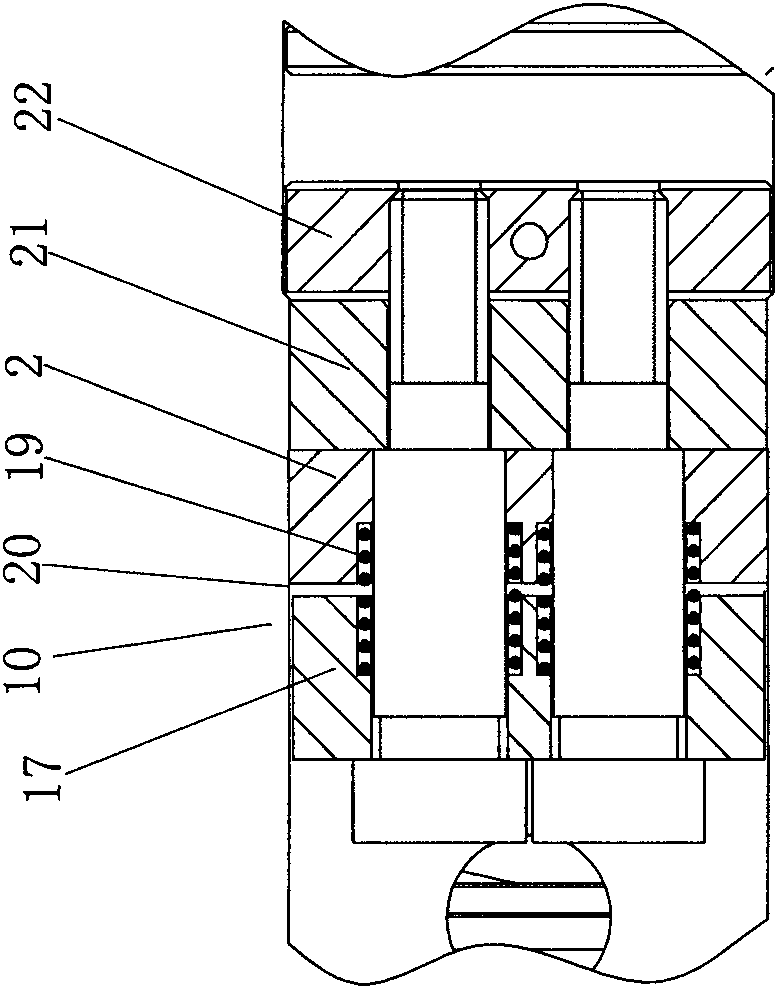

[0020] refer to Figure 1 ~ Figure 3 , the electric print head device is characterized in that it includes a casing 1, a casing back seat 2, a punch rod 3, a punch 4, a forward electromagnetic coil 5, a return electromagnetic coil 6, a return spring 7, and a stroke adjustment stud 8 , the punch tailstock 9 and the return buffer mechanism 10, wherein the punch 4 is slidingly fitted in the housing 1, its front end section 11 exposes the front of the housing 1, and its rear end section 12 exposes the housing 1, the punch 4 is fixed on the front end section 11 of the punch rod 3, the punch tailstock 9 is fixed on the rear end section 12 of the punch rod 3, and the front punch electromagnetic coil 5 is installed on the front part of the cavity of the housing 1 outside the punch 3, the return electromagnetic coil 6 is installed on the rear part of the cavity of the housing 1 outside the punch 3, and the rear seat of the housing 2 The return buffer mechanism 10 is installed on the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com