Storage cabinet stock material real-time metering method and device for tobacco production

A real-time measurement and material technology, applied in the direction of measuring devices, storage devices, weighing equipment for continuous material flow, etc., can solve the problems of not being able to measure in real time, and achieve production efficiency and product quality, low cost, and simple measurement methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

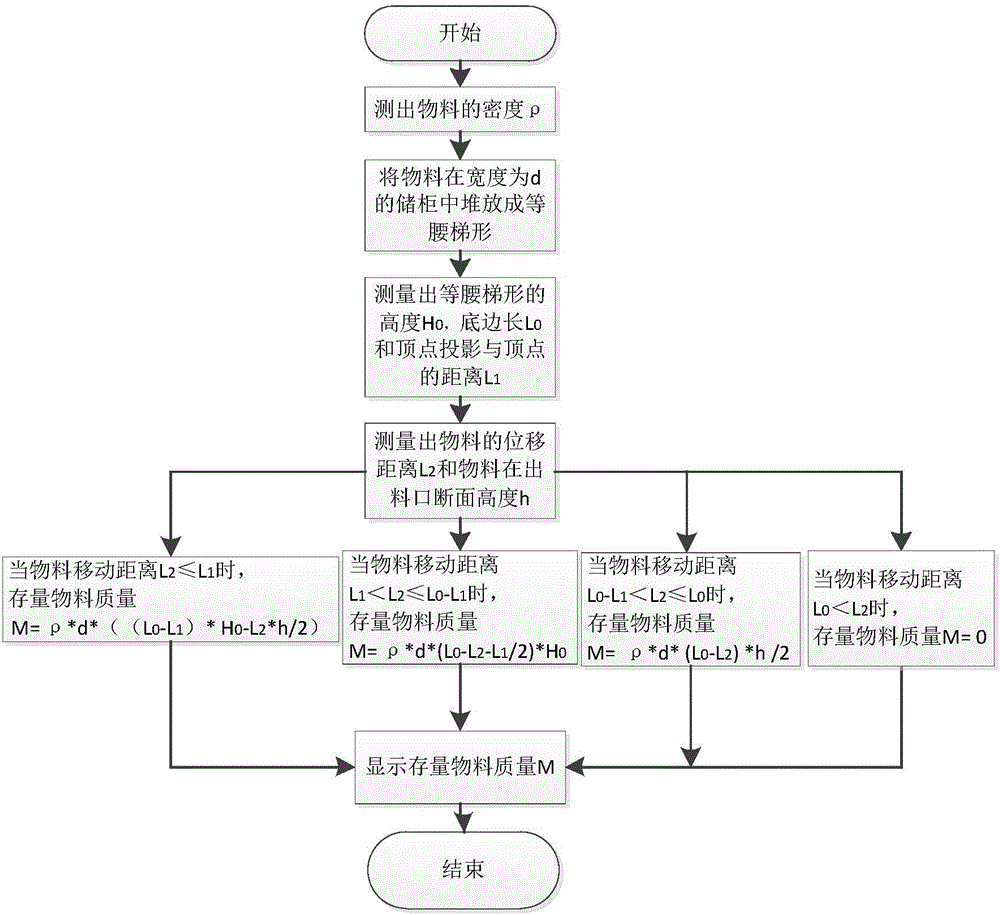

Method used

Image

Examples

Embodiment Construction

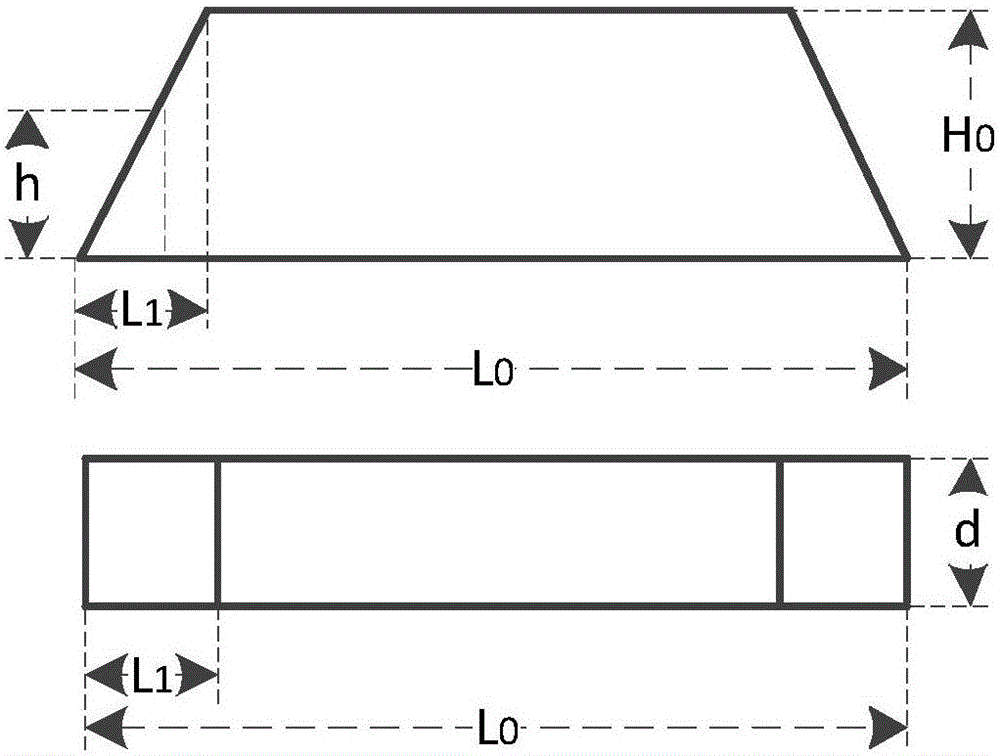

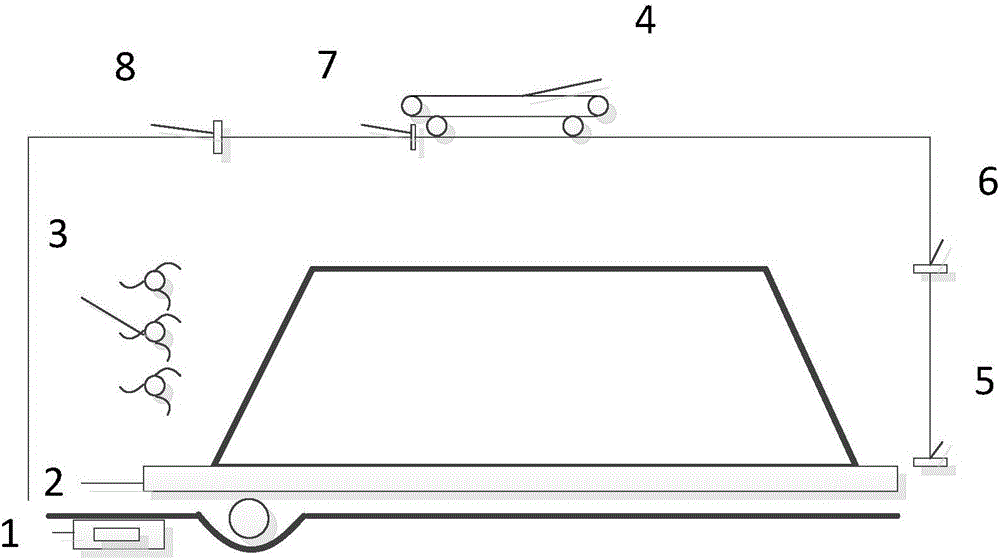

[0052] This embodiment provides a real-time metering system for storage materials in tobacco production storage cabinets, such as image 3 As shown, 1 is the outlet vibrating groove, 2 is the discharge bottom belt, 3 is the rake roller, 4 is the feeding truck for the cabinet, and 5, 6, 7, and 8 are all distance measuring sensors, which are installed on the storage cabinet. The function of the feeding truck 4 in the cabinet is to put the material into the storage cabinet and stack it into a shape whose longitudinal section is an isosceles trapezoid, such as figure 2 As shown, distance measuring sensors 5, 6, 7, 8 are used to directly or indirectly obtain the height H of the above-mentioned isosceles trapezoid 0 , base length L 0 , the projected length L of the hypotenuse in the horizontal direction 1 , material displacement L 2 and the height h of the material at the material outlet, the function of the outlet vibration trough 1, the discharge bottom belt 2 and the rake rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com