Packaging structure and method of infrared thermal pile sensor

A packaging structure and packaging method technology, which is applied in the manufacture/processing of thermoelectric devices, the use of electric/magnetic devices to transfer sensing components, thermoelectric device components, etc., can solve the problems of large volume and complex process, and achieve integrated packaging. , the effect of shortening process steps and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

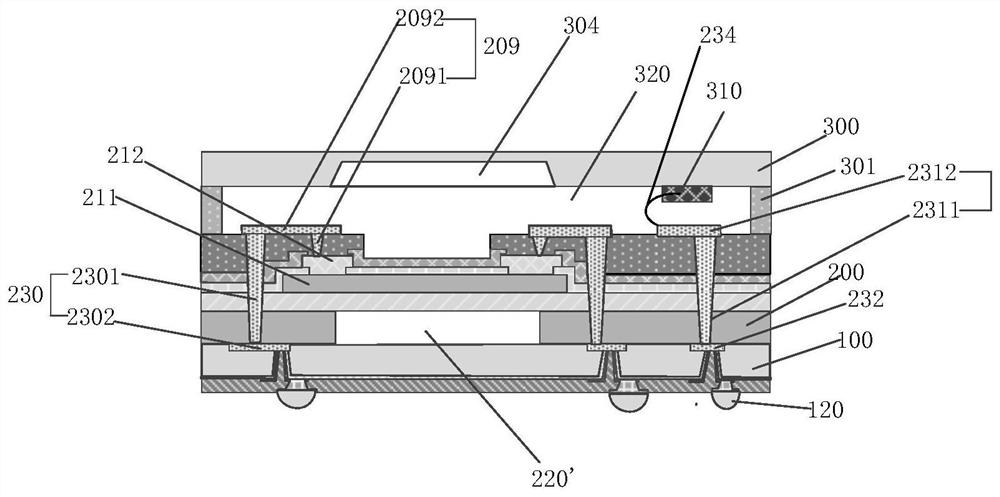

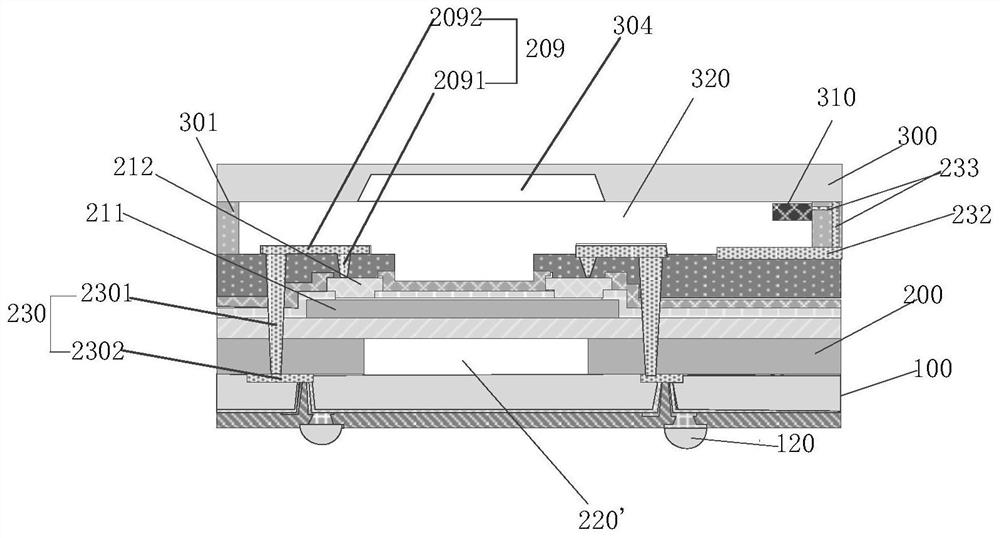

[0036] In order to solve the above problems, this embodiment provides a package structure of infrared thermal pile sensors, such as figure 1 shown, including:

[0037] the first substrate 200;

[0038] A thermopile structure located on the first surface of the first substrate 200, the thermopile structure includes a thermopile body composed of at least one set of thermocouple pairs;

[0039] The cover substrate is arranged above the thermopile structure and forms a first cavity 320 with the upper surface of the thermopile structure. The film-like thermistor 310 is arranged on the cover substrate.

[0040] The cover substrate has a first surface and a second surface, the first surface is the surface where the cover substrate and the thermopile structure enclose the first cavity 320 , and the second surface is opposite to the first surface.

[0041] In this embodiment, the thermistor 310 is located on the first surface of the cover substrate; in one embodiment, the thermistor ...

Embodiment 2

[0082] This embodiment provides a method for packaging an infrared thermal pile sensor, including:

[0083] S01: providing a first substrate;

[0084] S02: forming a thermopile structure on the first surface of the first substrate, where the thermopile structure includes a thermopile body composed of at least one set of thermocouple pairs;

[0085] S03: forming a cover substrate on the upper surface of the thermopile structure, and connecting the cover substrate and the upper surface of the thermopile structure to form a first cavity;

[0086] S04: Forming a film thermistor on the cover substrate.

[0087] Step SON does not represent a sequence.

[0088] Figure 3 to Figure 11 It is a structural schematic diagram corresponding to the corresponding steps of the manufacturing method of a packaging structure of an infrared thermal pile sensor in this embodiment, refer to Figure 3 to Figure 11 , detailing the manufacturing method of the package structure of the infrared therm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com